Best Die Cut Gaskets for Water Sealing – Poron® or Bisco® Silicone Foam?

July 18, 2017

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignGaskets are everywhere and all engineers today understand their importance in the creation of reliable, quality products. Die cut gaskets are used in everything from medical equipment; to military hardware; to the hand-held devices that most of us now carry 24 hours a day. Effective gaskets are designed to shield sensitive electronic components from the environment, vibration, heat, dust, air leaks, electromagnetic interference, and the nemesis of all electronics - water.

If you've ever dropped your cell phone, you know it's hard to keep in what's meant to be kept in! But worse, if you drop it in water, you know it's even harder to keep out what's meant to be kept out! Knowing that water resistance does not mean waterproof, designers must consider gaskets that resist sprayed or splashed liquids, and more importantly, complete under pressure immersion.

Read the Guide: Designing for Success - Die Cut Gaskets

So how can designers ensure that their sensitive electronics are protected from the harmful effects of water? Sealing foam, a foam gasket, insulating foam sealant, spray foam and other gasket sealing materials prevent air leaks, cracks and moisture exposure.

Let's look at a couple of Industry Associations which develop and define standards for electronics manufacturers, and provide the guidelines needed to choose materials for successful seals.

- The National Electrical Manufacturer's Association (NEMA) is the largest trade organization of electrical equipment manufactures in North America, and develops standards for safe and effective design, installation and use of electrical and medical imaging products. They use a ratings schema for electrical enclosures which can be found in this NEMA link.

- The Underwriters Laboratories (UL) tests representative samples of products or services to determine if they meet the stringent UL's requirements. When successfully validated, UL authorizes the manufacturer as certified to use the UL trademark.

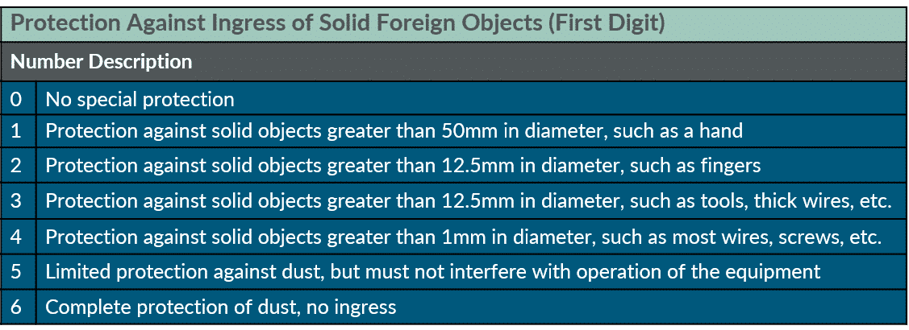

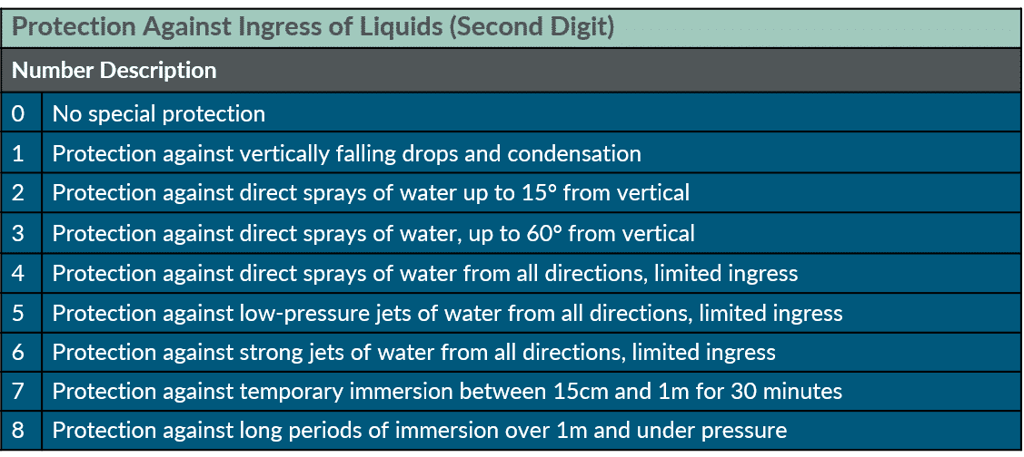

- The International Electrotechnical Commission (IEC) sets Ingress Protection (IP) standards to ensure that electronic equipment, components and parts fit and work safely together. They have established a set of international standards and conformity assessment systems which define the requirements of protection against solid foreign objects and liquids. See the charts below.

There are a lot of decisions to be made when considering any type of seal. As you can see, for water protection, the IP67 or IP68 rating is definitely the most reliable. Using the Rogers Corporation material selection tool to assist you, you will find materials that meet, or even exceed, international standards .

Die cut gasket material comparison

Understanding the properties of the many materials used to create a custom gasket is a lot to know. Each material has unique advantages and disadvantages. Take a look at the informational chart below.

![]()

As you can see, no one material will suit every application, so your success depends on selecting the material best suited for your particular need. To really understand the effectiveness of each of these materials for custom gaskets water seals, it's helpful to see how they stack up against each other during testing.

Our partner, Rogers Corporation, continually performs controlled tests to ensure the water sealing properties of their materials. Measuring leakage rate, they test each of their materials underwater and under pressure at varying gasket compressions to provide accurate expectations of their polymers. With their years of providing reliable water resistant and water tight seals, you can count on Poron®, Bisco® and Poron® AquaPro™ to provide the exact protection you require in your design.

The best material is going to be the one that’s best suited for your application.

Obviously, your application should be the primary consideration when determining which material to choose. Let's look in depth at Poron® , Bisco® and Poron® AquaPro™ to see how they stack up against each other.

Poron®

Poron® is a cellular urethane foam, made by Rogers, that offers a broad range of design solutions for gaskets, seals, and energy absorption. Because of its unique manufacturing process, Poron foam is highly customizable and can be created in a range of densities to suit diverse applications. Poron gasket materials form a highly effective watertight seal when compressed above 50%.

Other benefits of Poron include:

- Excellent resistance to compression set

- High-energy absorption

- Low out-gassing

- Resistance to extreme temperatures

- Bondable surface

- Low hydrolysis

- No plasticizers to migrate

- High internal strength and dimensional stability

Image: Poron® cellular urethane foam (Courtesy of Rogers Corporation)

Poron® AquaPro™

The Poron® AquaPro™ family of cellular urethane provides the same excellent qualities expected of Poron in addition to further enhanced protection. Providing exceptional water sealing and long-term performance, the new AquaPro formulations require the lowest compression force of any Poron water sealing formulation in achieving a tight seal. Due to its greater closed-cell formulation, AquaPro is designed to meet the IP67 or IP68 watertight ratings needed for vacuum sealing applications or low closure-force requirements.

The Poron® AquaPro™ family of cellular urethane provides the same excellent qualities expected of Poron in addition to further enhanced protection. Providing exceptional water sealing and long-term performance, the new AquaPro formulations require the lowest compression force of any Poron water sealing formulation in achieving a tight seal. Due to its greater closed-cell formulation, AquaPro is designed to meet the IP67 or IP68 watertight ratings needed for vacuum sealing applications or low closure-force requirements.

Image: Poron® AquaPro™cellular urethane (Courtesy of Rogers Corporation)

Bisco® Silicone Foams

Bisco® Silcone Foams are incredibly resilient and also made by Rogers. Resistant to extreme temperatures, the line is versatile enough to be used in sealing, cushioning, insulation, and vibration isolation. Like Poron, Bisco Silicone Foams are available in a variety of densities to suit a range of applications.

Key characteristics of Bisco Silicone Foams include:![]()

- Extreme resistance to mechanical fatigue

- Meets the most stringent UL flame ratings

- Resistance to UV, ozone, extreme temperatures, and flame

- Compressible

- Excellent compression set and creep resistance

Image: Bisco® Silcone Foams (Courtesy of Rogers Corporation)

The Takeaway

Engineers should be aware that they have many materials to choose from when designing a die cut gasket designed for water sealing. Thankfully, engineers can take advantage of helpful tools for determining which materials will best suit their unique application.

Lastly, while we've stressed that there's no single material that will work in every application, some materials simply outperform the rest . By staying informed about the latest materials on the market today, engineers are sure to find materials that will meet or exceed the sealing ratings required for their design.

How do you choose materials for your designs?

Share your thoughts with us below and don’t forget to check out the AquaPro™ case study here.