Strategic Sourcing: What it Means from the Supplier Side

May 10, 2021

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignStrategic sourcing is a major buzzword these days, and there is plenty of information about what you should be considering when undergoing an initiative to move from a more traditional procurement model to a strategic sourcing model.

What is Strategic Sourcing?

Strategic sourcing is a procurement methodology or initiative that focuses on creating long term cost savings and improved strategic relationships with suppliers by making the procurement department a more strategic part of the organization. Often tactics used to execute a strategic sourcing initiative include spend analysis, market research, supplier evaluation and negotiations, as well as revisiting existing contracts.

This article is meant to help articulate what this shift toward strategic sourcing means from the suppliers you work with. Forward thinking suppliers will have already started making changes in order to make them a better strategic fit for customers looking to move in this direction.

Read on to find out how suppliers must shift to meet the demands of the strategic sourcing model, and what you should look for when identifying suppliers that will meet your needs for a fruitful long term relationship.

Supplier Consolidation Initiatives

Supplier consolidation is probably the most important part of a strategic sourcing initiative. Becoming more strategic with the vendors you work with means having stronger relationships with fewer suppliers.

The most important factor you have to consider is how you can accomplish more with fewer suppliers, meaning your suppliers have to be ready to support you across a larger variety of your needs.

At Modus, we are focused heavily on being that strategic supplier, the supplier who can be your go-to across a variety of needs and processes. As you are looking to strategically partner with suppliers more, we are interested in growing and changing to support those more strategic requirements of a supplier.

As such, we’ve invested heavily in the infrastructure and processes needed to support our partnership accounts across the entire product lifecycle.

When undergoing a strategic sourcing or supplier consolidation initiative you need to review supplier qualifications to find the right fit. In this process you’ll want to look for a supplier who can:

- Support you across a larger portion of the product life cycle

- Cover a larger variety of your capability requirements

- Provide vertically integrated solutions to reduce your risk

- Deliver rapid Engineering and Sales support

Product Development Life Cycle

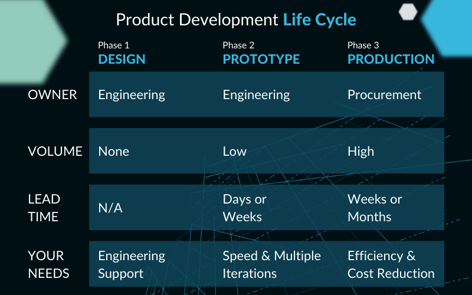

In order to reduce your number of suppliers, you need to find suppliers that are comfortable operating and partnering with you across more phases of your product design life cycle.

Design Phase

Early in the design phase, most engineers don’t even think to involve a manufacturing partner or supplier. But, we like to think differently.

The earlier you can involve us in the design phase, the more we can help you build a design that will ultimately perform to your specifications and be faster and less expensive to manufacture. Our team of engineers can also help give feedback on the overall design to make sure each component works well together, and you can efficiently manufacture each component.

(You wouldn’t believe the number of times we’ve been able to suggest a change to metal housing that made an FIP gasket about 10x easier to produce, bringing the entire part cost down.)

Prototyping Phase

In the prototyping phase, you care about speed. You are rapidly testing changes in your designs and working hard to get a minimum viable product (MVP) or a prototype that works the way you expect.

You’re interested in learning quickly and iterating on your design. This process usually takes months, but with the right partner you can achieve this in days or even weeks.

To do this, you’ll want a partner who is comfortable with small volumes and is prepared to support you on very quick turnaround parts. And this is much harder than it sounds. Many suppliers shy away from working on rapid prototyping because it is, quite honestly a huge disruption to traditional operations focused on large scale production runs.

At Modus, we see it a little differently. We love being involved in helping you get a prototype just right. There are a couple of key reasons that are beneficial to both your team and ours:

- Support of a Long Term Relationship: At Modus, we focus on the big picture, with a heavy emphasis on customer lifetime value, rather than a myopic focus on order-by-order revenue. Prototyping work is hard, but if we can help you get it right in this phase, we know we are poised to help you scale production (and we see that as a win for both of us!).

- Design Refinement: We also enjoy being a part of helping you refine your design to make sure it meets your requirements and is efficient to produce. Helping you refine a prototype allows us to give input when it can still change the outcome of your final product design.

So, we’ve built our business to support working with customers on rapid prototypes. In many cases, we can turn a prototype around in days when needed, and when the stars align, we can even occasionally turn it around same-day.

Product Launch Phase

Next up in your product life cycle is the launch phase. This is when you are ordering small initial runs of the product to get it out into the field to initial users or even for user testing.

At this point, you are heavily focused on speed to market and starting to care more about the per-product cost to produce each item. Having a partner who can adjust production methods right alongside you is huge in this situation.

When we work with our customers in this, we often provide quotes with varying options for trade-offs between lead times and costs, so you get to choose what is most important. If delivering a product a week earlier is worth the extra effort, you can tell us and we are happy to put in that extra effort to get it to you.

Maintenance and Ongoing Production Phase

As you shift a product from early launch stages to ongoing production, your primary goal will shift toward reducing unnecessary costs and finding the most efficient way to produce your final product.

This is where most suppliers want to live on a regular basis, and how they’ve structured their operations. And this is precisely why it is so hard to find a great supplier that can do this well and still deliver prototype runs as fast as you’d want.

At Modus, we pride ourselves on serving you every step of the way leading up to this phase in order to make sure we can most efficiently and effectively serve you in this phase. What we learn, and how we can help shape your design, in the early stages of product development makes a massive impact on how efficient we can ultimately make the long term production of your product. And who wouldn’t want that?

A Breadth Manufacturing Capabilities

So, how can you find a manufacturing partner that can support you all the way from prototype through production? The easy answer is to find a partner that has a breadth of manufacturing capabilities.

As your goals shift across the product life cycle, different manufacturing processes may be best suited to your needs. For instance, when prototyping a custom gasket or thermal pad, digital or CNC cutting may be the best fit to get small volumes across the finish line fast. And with no hard tooling required, it also means you have the flexibility to rapidly change the design as you test your prototype.

As you shift that very same gasket into large scale production, suddenly die cutting may be the best fit for high volume production to keep overall costs at a minimum and maintain a consistent production schedule where lead times are less crunched.

Additionally, the more manufacturing capabilities a single supplier has in house, the more of your parts they can provide from a single point of contact and under one roof. This means lower risk, less time spent overseeing and communicating with vendors, and likely better customer service from a supplier that deeply values your relationship.

Vertical Integration

Yet another consideration factor when determining if a partner is a good fit for supplier consolidation under a strategic sourcing model is how that partner has built processes to reduce your risk and take even more work off your plate.

Looking at the RF shield production process for instance, a traditional procurement strategy would mean sourcing the machining of the shield, FIP gasket dispensing, plating and addition of thermal materials all from separate vendors.

When looking for a partner who can support a strategic sourcing initiative, you’d instead look for a single manufacturer who can consolidate all of those individual processes under one roof.

A partner with a high degree of vertical integration removes both effort and risk from your team, and when there is no shipping required between each step of a manufacturing process, it saves significantly on both time and freight cost.

The Bottom Line

If you are undergoing a strategic sourcing initiative, you’ll need suppliers who are ready to jump in alongside you and build a mutually beneficial long term relationship. Many suppliers who are used to operating in the “traditional” model simply aren’t poised to make the transition with you today. To truly get the most out of a supplier consolidation effort, make sure you take all of the considerations above into account.