Modus Advanced, Inc. Waterjet Cutting Tolerances

October 27, 2020

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignCustomers have a lot of options when it comes to selecting a manufacturing process to make their part. We often get questions on which method to choose based on the desired outcome.

The most common types of cutting you will see are:

- Laser

- Digital

- Die

- Waterjet

There is no definitive best option. Each has its specific uses and benefits. Generally, your choice of cutting is determined by your material and your project. Waterjet cutting is an optimal choice for specific applications.

The benefits of waterjet cutting are:

- Clean cut

- Low heat

- High precision

- Environmentally friendly

- Many material options

- No hard tooling

Waterjet cutting is the go-to for cutting materials that are heat-sensitive and require high precision, both of which we see every day.

Why is High Precision Cutting important?

Tight tolerances and high quality are standards in the industries we serve. Every day we handle projects in defense, aerospace, medical, communications, and more. In these demanding industries, the difference between a successful project and a failure is often tied to the tolerances we can achieve with our cutting process. Waterjet cutting is often a great solution when tight tolerances are required.

Machine Tolerances

When we discuss tolerances in industrial cutting applications, we are really talking about accuracy. Waterjet cutting has two primary forms of accuracy:

- Repeatability – how closely it can hit a specific point, over and over again.

- Linear straightness – how straight of a line the machine can draw.

The Mach 4

For our waterjet cutting, Modus uses the Mach 4 from Flow. In our opinion, it is groundbreaking for its flexibility, precision, and reliability. There is no other waterjet on the market that can compete in speed or accuracy. Its stats are:

- Repeatability: +/-0.03mm

- Linear straightness: +/-0.038mm/m

Material Tolerances

Machine tolerances are the best in the industry but we aren’t cutting in a perfect world. Every material has its tolerances. Materials can change as we expose raw materials to the heat or abrasion of the cutting process. Some are even sensitive enough that the ambient temperature and environment will affect the results. That means there is some variance over the peak performance of the machine to account for.

At Modus, we have a database of the products and processes we have seen firsthand. We track how the materials respond and the closest cuts we can get by the thickness and material type.

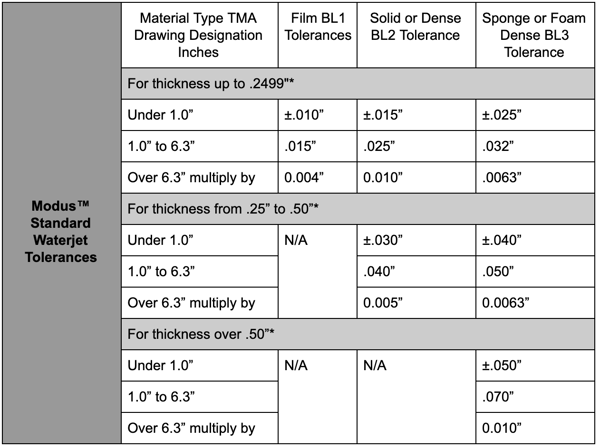

The standard tolerances for our waterjet are:

*Separate schedules of length and width tolerances are listed for different thicknesses of these materials because of the “dish” effect in die-cutting. This is more noticeable as the thickness increases. The “dish” effect is a concavity of die-cut edges (due to the material’s squeezing by the pressure of the cutting die). The length or width on the top and bottom surfaces are slightly more significant than the center’s height or width.

A full table of our standard tolerances can be found here.

High Precision Cutting

Your standards are our priority. We understand your project isn’t as simple as a reference guide, and clients come to us for more than the “industry standard.” That’s why we have Process Capability Indices, or CPK study available for all of our cutting methods. When you need tolerances tighter than we have listed or are working with less predictable materials but still need those tight tolerances—we utilize this test method.

We’ll make a specific number of parts, and measure each one to ensure we can meet your standards, every time. And this test won’t take weeks to complete. Depending on our current manufacturing schedule, we can see the results in days, not weeks, keeping your project moving along quickly.

Taking your Idea-to-Ignition™

We know just how important precision is. Taking your idea to ignition is challenging and involves a lot of variables. Modus Advanced, Inc. is here to take unknowns out of the equation. We operate with speed & precision. This coupled with our years of experience, level of expertise, and our proven processes makes us the obvious choice for your cutting needs.

You can have confidence that your parts will show up when you need it, and exactly to spec. Modus is the Obvious Choice when you need a trusted partner. Contact us and get a quote today.