Educational Resources

Custom Manufacturing Services for Satellite Components Resource Center

Browse all of our educational resources about Custom Manufacturing Services for Satellite Components.

Guide Articles Case Study.png?width=1024&height=768&name=Pillar%20Hero%20%20Custom%20Manufacturing%20Services%20for%20Satellite%20Components%20(1).png)

Custom Manufacturing

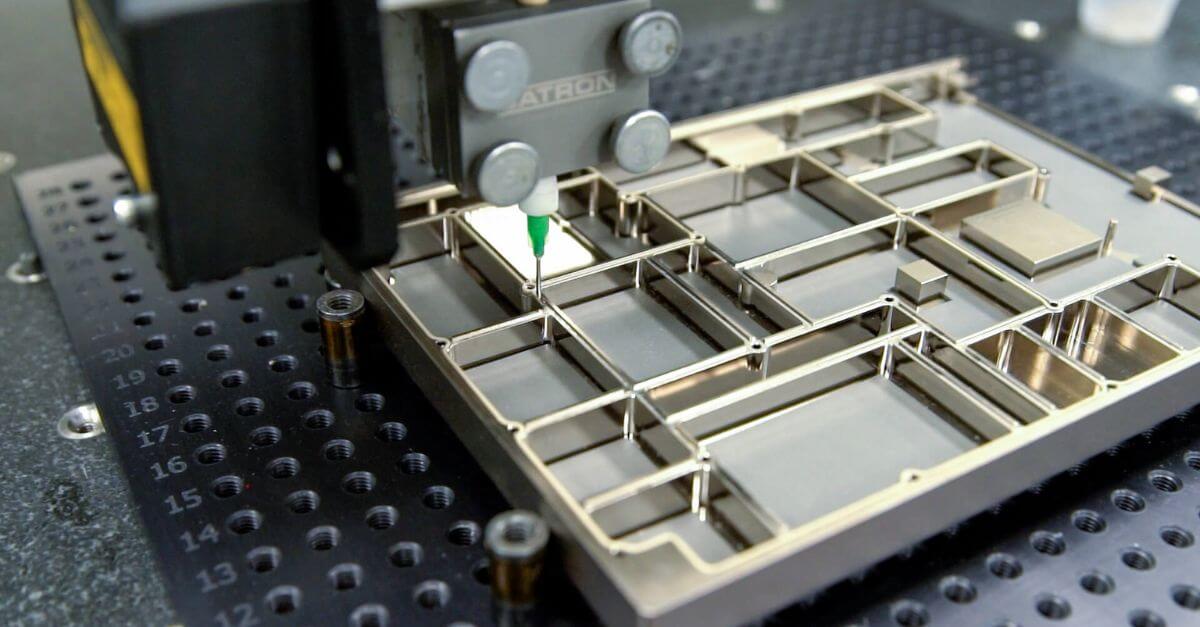

What are Custom Manufacturing Services for Satellite Components?

Custom manufacturing services for satellite components involve the precision fabrication of mission-critical parts — including RF shields, thermal interfaces, EMI gaskets, and machined housings — engineered to withstand the extreme thermal cycling, radiation, and vacuum conditions of space. These services typically span from rapid prototyping through production volumes, transforming specialized materials into components that meet the exacting tolerances and quality standards required for satellite bus systems, communications payloads, and optical assemblies.

Guide

Download the Custom Manufacturing Services for Satellite Components Guide

Understand the challenges of satellite component manufacturing and how integrated, compliant production processes accelerate delivery, reduce risk, and ensure mission success. Read everything right on page (no form fill required), or get a PDF to keep!

Read the GuideFeatured Articles About Custom Manufacturing Services for Satellite Components

Component Manufacturing Services for Satellite Sensors

Expert satellite sensor component manufacturing services with vertically integrated precision machining, RF shielding, thermal management, and space-qualified coatings. CMMC Level 2 and AS9100 certified for defense programs with 99.5% quality rates.

Component Manufacturing for Satellite Bus Manufacturers: Precision Solutions for Space Applications

Precision satellite bus component manufacturing with vertical integration, AS9100 certification, and CMMC Level 2 compliance. CNC machining, RF shielding, thermal management, and FIP gaskets for space applications.

Working with CMMC-Compliant Satellite Components Manufacturers

Learn how CMMC-compliant satellite components manufacturers protect your designs while delivering precision machining, RF shielding, and thermal management solutions that meet AS9100 aerospace standards for defense and commercial satellite programs.

Guide to Outsourcing Satellite Manufacturing for Parts and Components

Learn how outsourcing satellite manufacturing accelerates development timelines while maintaining quality. Discover vertical integration advantages, compliance requirements, and partner selection criteria for mission-critical space components.

Satellite Payload Component Manufacturing: Engineering Components for Space Missions

Discover precision satellite payload component manufacturing with vertically integrated processes including CNC machining, RF shielding, and FIP gaskets. AS9100 certified, CMMC Level 2 compliant for defense programs.

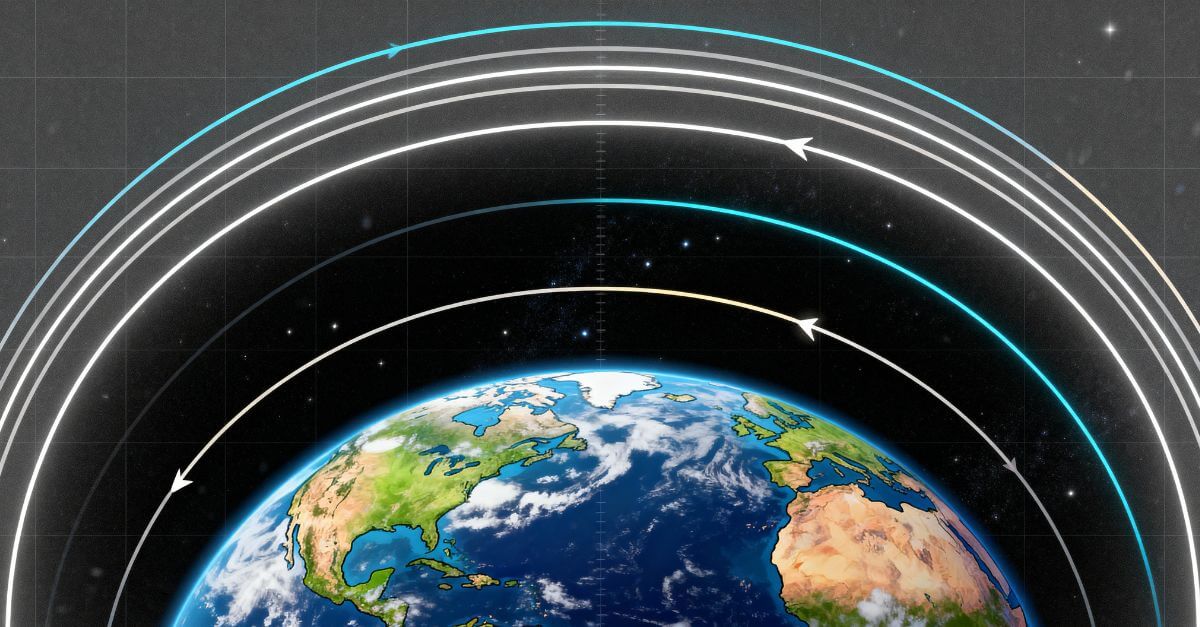

Orbital Transfer Vehicle Component Manufacturing: Precision Services for Space Missions

Learn about precision orbital transfer vehicle component manufacturing with vertically integrated metal machining, RF shielding, thermal management, and converting services. AS9100 certified with CMMC compliance for defense applications.

Satellite Constellation Component Manufacturing: Mission-Critical Solutions for LEO Systems

Discover precision satellite constellation component manufacturing for LEO systems. Space-grade CNC machining, RF shielding, FIP gaskets & thermal management with CMMC/DFARS compliance for mission-critical space applications.

Component Manufacturing for Satellite Communication Systems: Precision Engineering for Space Applications

Discover precision component manufacturing for satellite communication systems with CNC machining, RF shielding, and FIP gaskets. AS9100 certified with ITAR compliance for space-grade quality.

Satellite Bus Thermal Coatings: Engineering Solutions for Mission-Critical Temperature Control

Discover satellite bus thermal coatings for mission-critical temperature control in extreme space environments. Learn material properties, application requirements, and coating selection criteria for aerospace missions operating from -180°C to 121°C.

Case Study

When Standard Manufacturing Processes Won't Cut It: Engineering Custom Solutions for Space-Critical Components

See how custom waterjet process achieves tight tolerances for space-critical aerospace components through innovative engineering.

See HowSubmit Your Design

Get Design Feedback from Our Team

Have a design that needs feedback? Get in touch with our engineering team today to get real-time feedback on how to make your design more effective and manufacturable.

Submit a Design

Get Started

Speak to an Engineer Today

Don’t take our word for it. Reach out and speak to one of our engineers about your part today and see the benefits for yourself. We strive to turn all quotes around 48 hours or less to get your part moving as quickly as possible.

Submit a Design