Thermal Management in Electronic Devices: Design for Manufacturing Best Practices

July 25, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Early design integration: Incorporating thermal management considerations during the initial design phase prevents costly redesigns and ensures optimal heat dissipation performance

- Material selection impact: Choosing appropriate thermal interface materials and heat dissipation components directly affects device reliability and manufacturing complexity

- Manufacturing process alignment: Design decisions must account for production capabilities, assembly sequences, and quality control requirements to achieve consistent thermal performance

- Testing and validation: Implementing comprehensive thermal testing protocols during the design phase ensures devices meet performance specifications under real-world operating conditions

- Cost-benefit optimization: Balancing thermal performance requirements with manufacturing feasibility creates more efficient production processes and better end-product reliability

Understanding Thermal Challenges in Modern Electronics

Electronic devices generate heat as an inevitable byproduct of operation, and managing this thermal energy has become increasingly critical as components become more powerful and compact. Thermal management in electronic devices directly impacts performance, reliability, and safety across all applications from consumer electronics to mission-critical medical and aerospace systems.

The consequences of inadequate thermal management extend far beyond simple performance degradation. Excessive temperatures can cause component failure, reduce device lifespan, and create safety hazards in critical applications. In medical devices, thermal issues can compromise patient safety, while in aerospace systems, they can lead to mission-critical failures.

Modern electronic systems operate in environments where thermal loads continue to increase due to higher power densities and smaller form factors.

Definition

What is Power Density?

Power density refers to the amount of electrical power consumed per unit volume of the device, typically measured in watts per cubic centimeter.

Learn MoreThis trend makes thermal management for electronics a primary design consideration rather than an afterthought. Engineers must balance heat generation, heat transfer mechanisms, and manufacturing constraints to create devices that perform reliably throughout their operational lifecycle.

Read the Complete Engineer's Guide to Thermal Management

Design for Manufacturing Considerations in Thermal Management

Effective thermal management begins during the conceptual design phase, where engineers can make decisions that significantly impact both thermal performance and manufacturing feasibility. The design for manufacturing (DFM) approach ensures that thermal solutions are not only technically sound but also practical to produce at scale.

Manufacturing constraints directly influence thermal management strategies. Assembly processes, material availability, and production equipment capabilities all affect how thermal solutions can be implemented. Engineers must consider these factors early to avoid expensive redesigns later in the development cycle.

The integration of thermal management components into the overall device architecture requires careful coordination between mechanical, electrical, and thermal engineering teams. This collaboration ensures that thermal solutions complement rather than complicate the manufacturing process.

Critical Design Phase Decisions

Several key decisions made during the design phase have lasting impacts on thermal management effectiveness and manufacturing efficiency:

- Component placement and spacing: Strategic positioning of heat-generating components affects thermal distribution and influences the complexity of thermal management solutions

- Thermal pathway design: Creating efficient heat transfer paths from sources to sinks requires careful consideration of material properties and manufacturing capabilities

- Interface design: Proper specification of thermal interfaces ensures consistent performance while maintaining assembly feasibility

- Testing accessibility: Designing devices with accessible thermal measurement points enables quality control during manufacturing

Material Selection for Optimal Thermal Performance

Material selection represents one of the most critical aspects of thermal management design, directly affecting both performance and manufacturing complexity. Engineers must evaluate thermal properties alongside manufacturing requirements to select materials that deliver optimal results for thermal management in electronic devices.

Thermal interface materials (TIMs) serve as the bridge between heat sources and heat sinks, requiring careful selection based on thermal conductivity, application method, and manufacturing compatibility.

Definition

What is Thermal Conductivity?

Thermal conductivity measures a material's ability to conduct heat, expressed in watts per meter-kelvin (W/mK), where higher values indicate better heat transfer capability.

Learn MoreDifferent TIM types offer varying advantages in terms of performance and production efficiency.

Thermal Interface Material Performance Comparison

Material Type | Thermal Conductivity (W/mK) | Application Method | Manufacturing Complexity | Typical Applications |

Thermal Pads | 1.0 - 8.0 | Assembly placement | Low | General electronics |

Thermal Paste | 2.0 - 12.0 | Manual/automated dispensing | Medium | High-performance computing |

Phase Change Materials | 3.0 - 8.0 | Pre-applied/dispensed | Medium | Automotive electronics |

Thermal Adhesives | 1.5 - 5.0 | Dispensing/screen printing | High | Permanent assemblies |

Gap Fillers | 1.0 - 6.0 | Compression fitting | Low | Irregular surfaces |

The selection process must account for operating temperature ranges, mechanical stress requirements, and long-term reliability expectations. Materials that perform well in laboratory conditions may present challenges during high-volume manufacturing due to application complexity or quality control requirements.

Environmental factors also influence material selection. Devices operating in harsh conditions require materials that maintain thermal performance across wide temperature ranges while resisting degradation from humidity, vibration, or chemical exposure.

Heat Dissipation Strategies and Implementation

Effective heat dissipation requires a systematic approach that considers heat generation sources, transfer mechanisms, and environmental constraints. Engineers must design thermal paths that efficiently move heat from critical components to the surrounding environment.

Passive cooling solutions often provide the most reliable and cost-effective thermal management for many electronic applications.

definition

What is Passive Cooling?

Passive cooling relies on natural heat transfer mechanisms like conduction, convection, and radiation without requiring external power or moving parts.

Learn MoreThese systems rely on natural heat transfer mechanisms and require minimal maintenance while offering excellent long-term reliability.

Active cooling systems introduce additional complexity but can achieve superior thermal performance in high-power applications.

definition

What are Active Cooling Systems?

Active cooling systems use powered components such as fans, pumps, or thermoelectric coolers to enhance heat transfer beyond natural mechanisms.]The integration of fans, pumps, or thermoelectric coolers requires careful consideration of power consumption, reliability, and manufacturing complexity.

Learn MorePassive Cooling Design Strategies for Electronic Devices

- Heat sink optimization: Designing heat sinks with appropriate fin density, surface area, and mounting methods ensures efficient heat transfer while maintaining manufacturing feasibility

- Thermal spreading: Using heat spreaders or thermal planes distributes heat over larger areas, reducing hot spots and improving overall thermal management

- Natural convection enhancement: Optimizing device orientation and ventilation paths maximizes natural airflow without requiring additional components

- Radiation enhancement: Increasing surface emissivity through coatings or surface treatments improves radiative heat transfer

Manufacturing Process Integration

Thermal management solutions must integrate seamlessly with existing manufacturing processes to ensure consistent quality and production efficiency. This integration requires understanding how thermal components affect assembly sequences, quality control procedures, and overall manufacturing complexity.

Assembly processes significantly impact thermal interface performance. Automated assembly lines require thermal solutions that can be applied consistently with minimal variation. Manual assembly processes may allow for more complex thermal solutions but introduce variability that must be controlled through proper procedures and training.

Quality control procedures must include thermal performance verification at appropriate stages of manufacturing. This verification ensures that thermal management systems function as designed and meet performance specifications before final assembly.

Manufacturing Compatibility Assessment Framework

Process Stage | Thermal Considerations | Quality Control Points | Potential Issues |

Component Placement | TIM application uniformity | Visual inspection | Air bubbles, uneven coverage |

Assembly | Compression consistency | Torque verification | Over/under compression |

Curing/Bonding | Temperature/time control | Process monitoring | Incomplete curing |

Final Test | Thermal performance | Temperature mapping | Performance variation |

Manufacturing environments can affect thermal material properties and application procedures. Temperature and humidity control during assembly ensures consistent thermal interface performance and prevents contamination that could degrade thermal transfer.

Storage and handling procedures for thermal materials require special attention. Many thermal compounds have limited shelf life or specific storage requirements that must be maintained throughout the supply chain and manufacturing process.

Testing and Validation Protocols

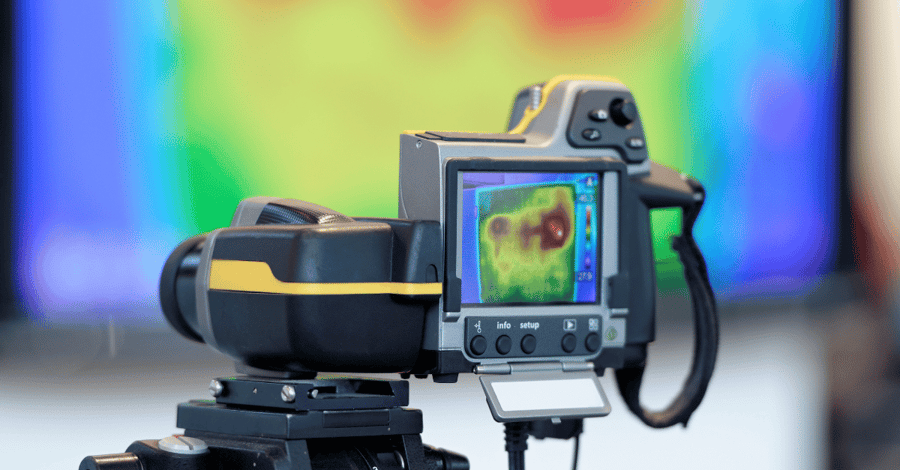

Comprehensive testing and validation ensure that thermal management systems perform as designed under real-world operating conditions. Testing protocols must evaluate both steady-state and transient thermal behavior to verify design performance.

Thermal testing during the design phase identifies potential issues before manufacturing begins.

Definition

What are Steady-State Thermal Conditions?

Steady-state thermal conditions occur when temperatures stabilize and heat input equals heat output, while transient conditions involve changing temperatures as the system reaches equilibrium.

Learn MoreThis early validation prevents costly redesigns and ensures that thermal management systems meet performance requirements across expected operating conditions.

Production testing verifies that manufactured devices meet thermal specifications and perform consistently. These tests must be efficient enough for manufacturing environments while providing adequate coverage of critical thermal parameters.

Essential Thermal Testing Parameters

- Steady-state performance: Measuring thermal resistance and maximum temperatures under continuous operation conditions

- Transient response: Evaluating thermal time constants and temperature rise rates during power cycling

- Environmental testing: Validating performance across specified temperature, humidity, and vibration ranges

- Aging effects: Assessing long-term thermal performance degradation through accelerated testing

- Manufacturing variation: Quantifying thermal performance variation due to manufacturing tolerances

Advanced Design Techniques for Complex Electronic Systems

Complex electronic systems require sophisticated thermal management approaches that address multiple heat sources, varying power levels, and dynamic operating conditions. These systems benefit from advanced design techniques that optimize thermal performance while maintaining manufacturing feasibility.

Thermal modeling and simulation tools enable engineers to evaluate design alternatives and optimize thermal management systems before physical prototyping. [DEFINITION: Thermal modeling uses computational methods to predict heat transfer behavior and temperature distributions within electronic devices under various operating conditions.] These tools help identify potential thermal issues and guide design decisions to ensure optimal performance.

Multi-physics simulation approaches consider the interaction between thermal, mechanical, and electrical systems. This comprehensive analysis ensures that thermal management solutions do not adversely affect other system performance parameters.

Advanced Thermal Design Considerations

- Thermal coupling effects: Understanding how heat transfer between components affects overall system thermal behavior

- Power management integration: Coordinating thermal design with power management systems to optimize overall efficiency

- Predictive thermal control: Implementing sensors and control algorithms that anticipate thermal loads and adjust cooling accordingly

- Modular thermal design: Creating thermal management systems that can be scaled or modified for different product variants

Quality Systems and Thermal Performance Assurance

Quality systems play a crucial role in ensuring consistent thermal performance across manufactured devices. These systems must address material control, process validation, and performance verification to maintain thermal management effectiveness.

Statistical process control techniques help identify and correct manufacturing variations that could affect thermal performance.

Definition

What is Statistical Process Control

Statistical process control uses statistical methods to monitor and control manufacturing processes, ensuring they operate within specified limits and maintain consistent quality.

Learn MoreThese methods enable continuous improvement of thermal management processes and ensure consistent product quality.

Documentation and traceability requirements ensure that thermal management materials and processes can be tracked throughout the manufacturing cycle. This capability is essential for quality investigations and continuous improvement efforts.

Frequently Asked Questions About Thermal Management for Electronics

What is the most important factor in thermal management design?

Early integration of thermal considerations during the initial design phase prevents costly redesigns and ensures optimal heat dissipation performance throughout the device lifecycle.

How do thermal interface materials affect manufacturing complexity?

Different thermal interface materials require varying application methods and quality control procedures, with thermal pads offering low complexity assembly while thermal adhesives require high-precision dispensing processes.

What are the key differences between passive and active cooling systems?

Passive cooling relies on natural heat transfer mechanisms without external power, offering reliability and low maintenance, while active cooling uses powered components for superior performance in high-power applications.

How can engineers optimize thermal management for manufacturing?

Engineers should consider component placement, thermal pathway design, material selection, and manufacturing process integration early in the design phase to ensure both thermal performance and production feasibility.

Partnering with Modus Advanced for Thermal Management Excellence

Modus Advanced brings deep engineering expertise and comprehensive manufacturing capabilities to thermal management challenges. Our team of engineers — representing more than 10% of our staff — understands the critical balance between thermal performance and manufacturing feasibility.

Our vertically integrated approach enables us to support thermal management projects from initial design consultation through high-volume production. This integration includes precision machining of heat sinks, application of thermal interface materials, and assembly of complex thermal management systems.

With AS9100 and ISO 9001 certifications, we maintain the quality standards essential for critical applications in aerospace, defense, and medical device industries. Our quality systems ensure that thermal management solutions perform consistently and reliably throughout their operational lifecycle.

Our rapid prototyping capabilities enable quick validation of thermal management concepts, helping engineers optimize designs before committing to production tooling. This approach reduces development time and ensures that thermal solutions meet performance requirements from the start.

When lives depend on reliable thermal management — whether in life-support medical devices or mission-critical defense systems — choose a partner who understands that one day matters. Contact Modus Advanced to accelerate your thermal management innovation and bring your critical technologies to market sooner.