What Could Happen when Vibration Isolation Isn’t Considered in the Design Stage

February 27, 2017

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Costly Design Modifications - When vibration isolation isn't considered during initial design, engineers often face expensive and time-consuming design modifications later to accommodate vibration mounts, significantly impacting project timelines and budgets.

- Performance and Safety Risks - Failing to address vibration issues can lead to potential operator injury, user discomfort, and equipment damage – critical considerations when determining if vibration mounts are necessary for your design.

- Delayed Problem Identification - Most vibration isolation issues aren't identified until problems arise in testing or real-world use, when it may be too late for simple solutions, as illustrated by the case study where a lab mixer caused test tubes to dance on a table.

- Engineering Efficiency Loss - Involving vibration specialists early in the design process prevents rework and accelerates development, supporting Modus Advanced's philosophy that "one day matters" in bringing products to market.

- Expertise Accessibility - Technical guidance for selecting the correct vibration mount is readily available through partners like Modus Advanced (an authorized LORD distributor), making vibration isolation planning more accessible than many engineers realize.

If you had called 877-ASK-LORD within the last several years, chances are you probably talked with me! Through my 34 years with LORD Corporation, I’ve had the opportunity to work as a Tool Engineer, designing all types of tooling used to manufacture LORD products; as a Product Engineer, providing design support to many of the LORD Industrial customers such as Caterpillar and John Deere; and most recently as an Application Engineer, providing technical support to LORD Industrial Distributors and their customers.

Helping you select the right vibration isolator

.png?width=250&name=Picture1%20(1).png) One morning while doing Application Engineering I received an internal call from Andy, who is one of the Technicians in the LORD Chemical Lab. “Dave, can you stop over for a few minutes? I need to show you something.” I stopped over and Andy showed me a new mixer that he had just installed on the lower shelf of one of the lab tables. Andy turned the mixer on and asked me to watch. The test tubes in stands on the top of the table were rockin’ and rollin’ and vibrating and ready to dive off the edge. “It’s kind of like the electric football game I had when I was a kid” I replied. “It appears that the frequency generated by the operation of the mixer is putting the lab table into resonance.” In other words, the natural frequency of the mixer, or disturbing frequency, is very close to the natural frequency of the lab table.

One morning while doing Application Engineering I received an internal call from Andy, who is one of the Technicians in the LORD Chemical Lab. “Dave, can you stop over for a few minutes? I need to show you something.” I stopped over and Andy showed me a new mixer that he had just installed on the lower shelf of one of the lab tables. Andy turned the mixer on and asked me to watch. The test tubes in stands on the top of the table were rockin’ and rollin’ and vibrating and ready to dive off the edge. “It’s kind of like the electric football game I had when I was a kid” I replied. “It appears that the frequency generated by the operation of the mixer is putting the lab table into resonance.” In other words, the natural frequency of the mixer, or disturbing frequency, is very close to the natural frequency of the lab table.

For ease of use, Andy certainly wanted to keep the mixer in close proximity to his work and asked what we could do to solve this vibration issue. Andy weighed the mixer and it was close to 60 pounds. We estimated the disturbing frequency to be somewhere between 15 to 25 Hz. I did a simple single degree-of-freedom calculation and determined that four LORD 156PD-16 multiplane plateform mounts should provide enough isolation to eliminate the problem.

Sure enough, when Andy installed the mounts, it did the trick and the vibration at the top surface of the lab table was drastically reduced. The test tubes on the table no longer danced or vibrated.

.png?width=429&name=Picture2%20(1).png)

.png?width=430&name=Picture3%20(1).png)

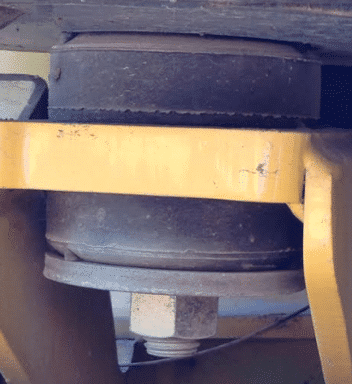

LORD Multiplane Plateform Mount 156PD-16 Shown Installed

Andy thanked me and said “I wish I knew this was going to happen from the beginning. I would have gotten you involved a lot earlier.” – Words we’ve heard again and again!

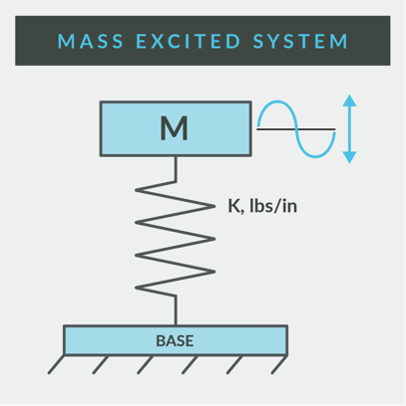

So, what do I mean by single-degree-of-freedom (SDOF)? Vibration is oscillatory motion. The simplest vibratory system consists of a single mass connected to a spring. It is referred to as single-degree-of-freedom because the motion will only occur in one direction. Because the oscillatory motion of the mixer was primarily in the vertical direction, I could apply equations based on a single degree-of-freedom system and could expect accurate results. Since the mixer was causing the disturbance and we were trying to keep the disturbance from affecting the lab table, we have what is known as a mass-excited system where the mass M represents the mixer, K represents the LORD 156PD-16 multiplane plateform mount, and the Base represents the lab table.

Single-Degree of Freedom

.png?width=417&name=Picture4%20(1).png)

As in Andy’s case, I wish that many of our customers would involve us earlier in the design process. Unfortunately, vibration isolation is usually not a consideration until there is a problem. At that point it may be too late and the customer may need to modify their design to accommodate a vibration mount that would improve the situation. As all engineers know, design modifications are time consuming and, maybe more importantly, costly! Therefore, the time to consider vibration is at the very beginning of the design phase!

Most OEM’s that I’ve dealt with know that they should use vibration mounts when attaching an engine to the frame rails of a vehicle or when mounting a cab onto the frame of a vehicle. In these cases they plan for vibration mounts in their design. Our trained staff can help to select the appropriate mount needed for your design. To make it easy, we can provide 3D models to add directly to your design to assure that the mount will have planned space to function properly. Click here to download LORD 3D models for free!

There are other components that cause disturbances, though, such as actuators, fans, electronics, or vehicle accessories that can be easily overlooked in the design process and the use of vibration mounts is only considered when vibration becomes a problem. When this happens, the customer's usual response is that they did not realize that vibration caused by these components would be an issue. In the worst case, redesign is necessary to provide adequate space to allow for vibration mounts in the system. Again, this amounts to additional time and cost, especially if the customer already has some equipment in the field. Nobody wants that to happen!

LORD 2-Piece Mount Installed on the cab of a Backhoe

Crew Working in Conjunction with a Wheel Loader

There are two important questions I recommend asking yourself when deciding whether a vibration mount is necessary to isolate a component causing a disturbance.

- Is there a potential for the operator or people near the equipment to become injured or to experience discomfort due to excessive vibration or noise if I do not use vibration mounts?

- Is there a potential that surrounding components or the component itself will be damaged or adversely affected if I do not use vibration mounts?

If the answer is yes to either of these questions, then you should consider using vibration mounts. Remember that you can always get technical assistance and guidance in selecting the correct mount for your system by calling on Modus Advanced, Inc., an authorized LORD Distributor, or linking to LORD Products on the website. Learn more about vibration from a LORD expert in the video below: