Guide

Parker LORD Vibration Isolation Mounts

Helping you select the right vibration isolator.

Download PDF

What's in the guide

What's in the guide

Understanding the adverse effects of vibration, shock, and noise disturbances is the first step in selecting an appropriate isolation solution. Problems range from simple annoyances to the more serious complications of shortened equipment life and especially safety.

In this paper, we'll discuss reliable and cost-effective solutions to isolate vibration and shock, accommodate motion, and decrease noise for optimal vibration isolation performance and reliability. Parker LORD isolators are designed to bring cutting-edge vibration and shock control management solutions to improve the quality of your products.

Don't have time to read this? Take a copy with you:

Download PDFTable of Contents

Select Your Chapter

A clearer understanding of this will promote a more efficient application of its principles and techniques and improve overall engineering competence wherever products are exposed to hostile dynamic environments.

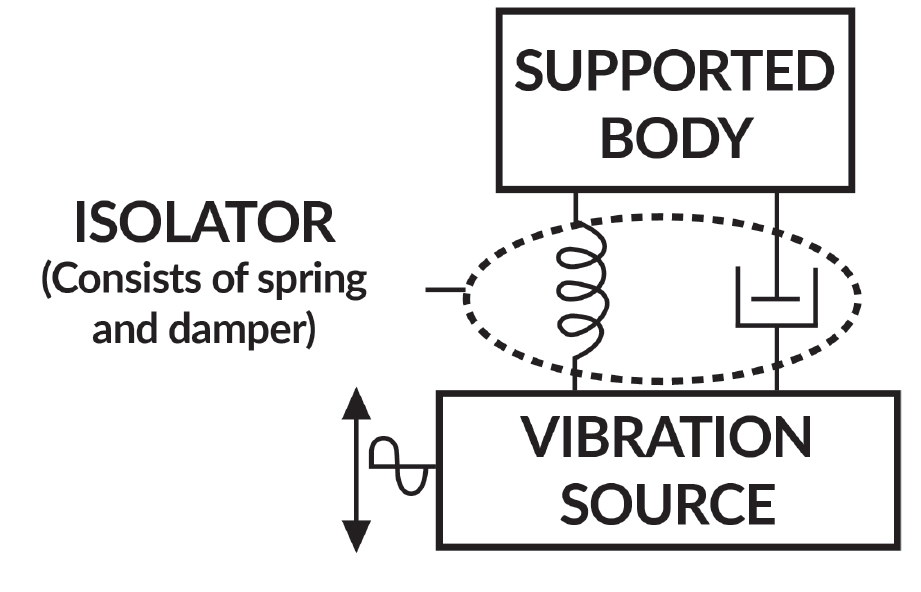

The only way to reduce vibration transmitted from a vibration source to the supported body is to permit relative motion. This is the function of the vibration isolators. The more isolation required; the more relative motion is needed. Isolators control the effect, not the cause. They reduce transmission of vibration from a vibration source to the attached structures or systems.

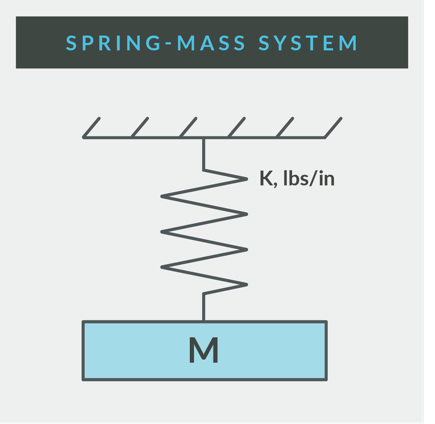

Vibration definition is explained as an oscillatory motion. Any body with mass and elasticity can vibrate. The simplest type of vibrating systems is called a single-degree-of-freedom spring-mass system. The spring is characterized by its spring rate and a mass.

This system is called a single-degree-of-freedom system because motion can occur in only one direction.

All single-degree-of-freedom problems can be classified into two groups:

- Mass excited system: protecting the supporting structure from vibratory disturbances originating in the supported mass.

- Base excited system: protecting the supported mass from vibratory disturbances of the supporting structure.

In the first case the mass moves because of the vibrating force. This causes a deflection across the spring which transmits a force to the structure. This force must be reduced.

In the second case the vibrating or moving structure causes a deflection across the spring which transmits a force to the supported mass. This causes the mass to move. The motion must be reduced.

What about more complex systems that move in more than one direction? A multiple-degree-of-freedom system occurs when there are two or more coordinates within its motion. Force and motion must be reduced.

Chapter 2

Shock

Shock is a common phenomenon with many familiar sources: aircraft landings, impacting of railroad cars, power surges, impacts in marine drive systems, driving over bumps, dropping product containers, explosions, or missile launching and staging.

Therefore, shock protection is a common requirement in good product design. In today’s trend to higher speeds, heavier loads, larger power plants and lighter weights, this accentuates the problem.

Mechanical shock is a nonperiodic disturbance of a mechanical system characterized by suddenness and severity. Such extreme disturbances cause significant forces in the system which may be damaging. A shock input is non-repetitive in nature and of limited time duration. The response it produces normally decays to an arbitrarily small value before the next disturbance.

Analysis of a shock problem usually starts with an examination of the shock input. Often these short-duration transient loads have complex wave shapes. Analysis may be simplified by comparing the actual wave shape to several simple wave shapes for which the response is known. Important features of the shock pulse are maximum amplitude, time duration, and approximate shape. The majority of excitations typically encountered are:

Half-sine shock pulse

Triangular shock pulse

Drop shock

Velocity shock

Case Study

Building a 10 Year Strategic Relationship

See how Modus has redefined the traditional supplier relationship and supported the strategic growth of this DoD telecommunications company.

See HowChapter 3

Vibration and shock terms and definitions

There are a number of terms and definitions which should be understood with regard to vibration and shock theory.

Acceleration is the rate of change of velocity with time, usually along a specified axis and usually expressed in “G” or gravitational units. It may refer to angular motion.

Amplitude is the maximum displacement from its zero-value position.

Compression when specified as a direction for loading is a deformation caused by squeezing the layers of an object in a direction perpendicular to the layers.

Damping the mechanism in an isolation system dissipates a significant amount of energy. This mechanism is important in controlling resonance in vibratory systems.

Disturbing frequency is the number of oscillations per unit time of an external force or displacement applied to a vibrating system.

Durometer (hardness) is an arbitrary numerical value, which measures the resistance to the penetration of the durometer meter indenter point; value may be taken immediately or after a very short specified time.

Fragility is the highest shock or vibration level that can be withstood without equipment failure.

“G” Level is an expression of the vibration shock acceleration level being imposed on a piece of equipment as a dimensionless factor times the acceleration due to gravity.

Isolation is the protection of equipment from vibration and/or shock. The degree (or percentage) of isolation necessary is a function of the fragility of the equipment.

Load deflection curve is the measured and recorded displacement of a mounting plotted versus an applied load.

Natural frequency is the number of cycles (expressed as Hertz or cycles per second) at which a structure will oscillate if disturbed by some force and allowed to come to rest without any further outside influence.

Random vibration is a non-sinusoidal vibration characterized by the excitation of a broad band of frequencies at random levels simultaneously.

Resonance vibratory system is said to be operating at resonance when the natural frequency of the disturbance (vibration or shock) coincides with the system’s natural frequency.

Set is the amount of deformation never recovered after removal of a load. It may be in shear or compression.

Shear when specified as a direction for loading is a deformation caused by sliding layers of an object past each other in a direction parallel to the layers.

Shock pulse is a transmission of kinetic energy to a system, which takes place in a relatively short length of time compared to the natural period of this system. It is followed by a natural decay of the oscillatory motion. Shock pulses are usually displayed as plots of acceleration vs. period of time.

Spring rate is the force required to induce a unit deflection of spring. A steel spring has a very linear relationship between force and deflection. Elastomeric springs may or may not be linear depending on the amount of deflection due to the load.

Static deflection is the deflection of the isolator under the static or deadweight load of the mounted equipment.

Transmissibility is a dimensionless unit expressing the ratio of the response vibration output to the input condition. It may be measured as motion, force, velocity or acceleration.

Resource Center

EMI Shielding Solutions for Aerospace & Defense Resource Center

All your EMI Shielding resources have been organized in one spot to help answer your most common questions regarding EMI shielding in aerospace and defense.

See HowChapter 4

Shock mounts and vibration isolators

Parker LORD offers a full range of sophisticated materials and products that with the proper application will allow products to operate more smoothly and quietly; less disturbing to surrounding equipment and personnel; less susceptible to damage; and less expensive to make.

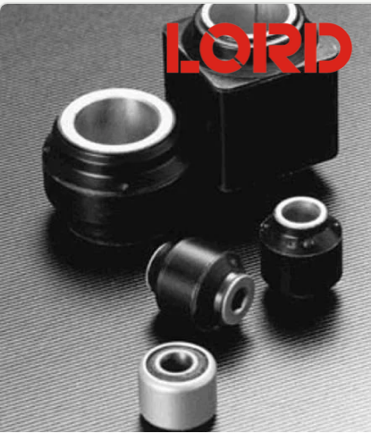

With more than 90 years providing innovation and solutions to their demanding aerospace, defense, automotive and industrial customers, Parker LORD elastomeric isolators set the International standard for compact, high-load, high-capacity anti-vibration mounts.

From vibration management systems to Parker LORD's high-performance rubber-to-metal vibration couplings, Parker LORD's Innovation, research, and expertise they feature a wide range of products to meet most applications as well as custom-designed vibration isolation system. This paper has been prepared to offer information needed to select and use rubber mounts, explain terms and definitions, understand theory, and deliver data for standard mounts.

Rubber bushings

Used in applications where the absorptions of shock, attenuation of noise, reduction of wear, and elimination of lubrication are required.

Center-bonded bushings

Center-bonded bushings are designed to be loaded radially and utilize a soft torsional spring rate to provide freedom in rotation. High radial restraint maintains the alignment between joined parts. They are not intended for use where extreme rotational motion will occur. Typical applications include heavy-duty highway equipment, drilling equipment, harvesters, combines, wheel suspensions, vibratory feeders, mobile power equipment, vibratory cable-layers, and industrial equipment.

Square-bonded bushings

Square-bonded bushings accommodate angular movement and isolate vibratory disturbances in heavy equipment. These bushings combine a torsional spring with an elastomeric pivot and isolator. They provide positive torsional positioning and pivot action under the most demanding operating conditions. Typical applications include wheel suspensions, vibratory feeders, mobile power equipment, and vibratory cable-layers.

Easy to install, the uncomplicated designs of the center-bonded and square-bonded bushings provide initial economy, while the rugged elastomers and high strength bonding assures extended service life with minimal maintenance.

Features and benefits:

Easy to install

Uncomplicated design provides initial economy

High-strength bonding assures extended service life

Minimal maintenance due to specially compounded elastomer

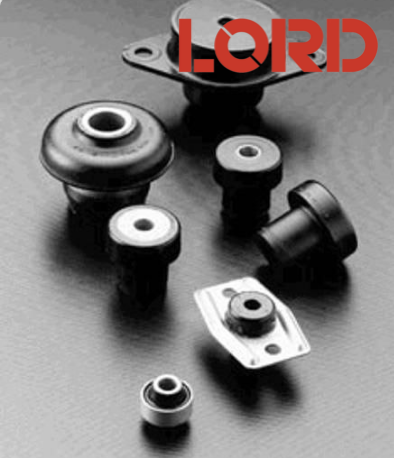

Center bonded mounts

Center bonded mounts are used in applications to isolate vibration, control shock, and reduce noise due to structure-borne vibrations. Available in a full range of rated load capacities and able to withstand shock loads of 10 g’s, these equipment mounts protect and improve operator comfort. They are ideal for automotive, marine, railroad and other industrial applications.

Center-bonded mounts provide flexible suspension systems for mobile, transport-mounted or portable equipment. Typical applications include engines, cabs, fuel tanks, pumps, air conditioning units, compressors, and industrial machinery.

Features and benefits:

Vibration isolation in all directions

Noise attenuation

Easy installation because of one-piece design

Low-cost installation

Long service life

Consistent performance because of permanently bonded design

Shock protection in all directions provided by cushioned rubber snubbers, no metal-to-metal bottoming

Standard sizes available from stock

Space-saving size

Captive installation after overload failure when recommended bolt, washer and nut are used

Accommodate English and Metric bolts

Dynaflex® couplings

These easily installed ring-type couplings were developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. They reduce the transmission of noise and increase bearing and driveline life through greater misalignment accommodation, isolation of low frequency disturbance, and isolation of torsional shock.

The highly flexible elastomeric couplings for accessory drives are also designed to eliminate lubrication and maintenance.

Features and benefits:

Misalignment accommodation – elastomeric flexibility allows for large angular misalignment.

Vibration isolation - low torsional spring rate is achieved with the elastomeric ring-type coupling using rubber in compression. This allows for low system natural frequencies and isolation of first mode driveline disturbances in most driveline systems.

Shock protection – isolates torsional shock, prevents backlash, and protects system components including bearings from fatigue failure.

Long service life – Dynaflex® LCR Series Couplings have proven themselves under demanding service conditions.

Maintenance-free – elastomer flexibility accommodates all motion without wear eliminating the need for lubrication.

Noise reduction – no metal-to-metal contact; elastomer attenuates structure-borne noise and isolates vibration from components that would act as noise generators.

Systems Engineering – Parker LORD has in-house computer capabilities for multi-torsional analysis to assist in proper coupling selection.

Flex-bolt™ sandwich mounts and cylindrical vibration isolators

Parker LORD Flex-Bolt™ Sandwich Mounts are designed to protect equipment and machinery against damaging vibration. This family of mounts has excellent capacity for vibration energy control.

Constructed with high-strength bonds and specially compounded elastomers, these mounts provide high load-carrying capacity and assure long life. The simple design and unitized construction provide low cost mounting systems that are compact, lightweight, easy to install, and maintenance-free.

Typical applications include business machines; motorcycles; heating, ventilating and air conditioning equipment, light motors, appliances, shipping containers, feeders, compactors, and vibratory rollers.

Features and benefits:

Economical

Compact and lightweight

Easy to install

Maintenance-free

Three size groups; small, medium and large

Unitized construction

Grommet isolators

Grommet Isolators provide effective, economical vibration isolation system for light loads. They are suitable for commercial and military applications including computers, disk drives, business machines, precision instrumentation and general industrial equipment.

Grommet isolators are designed and produced with the same type of precision and care as our high-performance bonded elastomeric mounts. This provides close control of stiffness and dimensions.

Made of neoprene and natural rubber provides close control of stiffness and dimensions. They also provide good vibration isolation for disturbing frequencies above 30 Hz.

Features and benefits:

Economical

Offer improved reliability in environments where harsh unwanted vibration and shock occur

Space saving

Oil resistant

Effective vibration isolation and shock protection for light load applications

Two-piece mounts

Two piece-mounts are designed for applications involving severe dynamic forces in the static load direction, as well as the rebound direction. Travel is limited in both directions by rubber in compression which provides snubbing.

These mounts are designed to support engines, cabs, and accessory units and accommodate frame racking and twisting while isolating vibration and absorbing shock.

Typical applications for two-piece mounts include backhoe mounts, excavator mounts, loader mounts, etc. used on-highway, off-highway vehicles, construction and industrial machines.

Features and benefits:

Dynamically effective in all directions

Prevents mechanical transmission of noise

Accommodate misalignment and distortion

High rebound capacity

Easy to install with common tools

Standard bolt torque assures proper assembly

Top and bottom parts alike – cannot be misassembled

Fail-safe assembly

Sized for English and Metric bolts

Long dependable service life

Economical

Machinery mounts

Machinery mounts are designed to support heavy equipment and isolate intermittent or continuous vibration. The result is greater machine accuracy, longer service life, smoother machine operation and reduced maintenance. These mounts are available in four types to suit smoother operation and reduced maintenance.

Lattice mounts are recommended for applications where disturbing frequencies are as low as 6 Hz. Their lattice design provides a soft vertical spring rate combined with lateral stability.

Typical applications include shakerscreens, sifters, rubber mills, air compressors, and large engines/generators.

Chan-L™ mounts are recommended for machines where vertical disturbing frequencies are 600 cpm or higher. Their elastomer-supported channel design features a soft vertical spring rate. The design incorporates built-in protection against metal-to-metal bottoming. Typical applications include separating and grading screens and shakeouts.

Industrial shock mounts efficiently control shock and structural noise transmission from heavy industrial machinery. Industrial shock mounts protect adjacent controls, sensitive instruments and precision machines from impact disturbances which could hamper their performance. Worker comfort is increased, and building structures need less maintenance.

Features and benefits:

High-efficiency multi-directional isolation of low-frequency vibration

Extremely rugged and require no maintenance

Easy to install

Long service life

Plateform mounts

Parker LORD plateform mounts provide effective isolation against vibration. The contour of the flexing element was developed to provide uniform stress distribution. This, plus high strength bonding and the use of specially compounded elastomers provides maximum service life.

These versatile mounts are available in three types, each type featuring square, diamond or holder configurations to suit a variety of design requirements.

The three types, plateform mounts, heavy-duty plateform mounts and multiplane mounts, offer a range in load ratings from 0.5 to 600 pounds. Snubbing washers provide an interlocking system of metal parts which act to prevent damage from overload or excessive shock impact.

Plateform mounts are easy to install and provide efficiency. Typical applications include electronic equipment, business machines, medical equipment, small pumps, engines, and gen sets.

Features and benefits:

Three types of mounts for different applications

Square, diamond or holder configurations to suit a variety of design needs

Load ratings from 0.5 to 500 pounds per mount

Uniform stress distribution

Easy to install

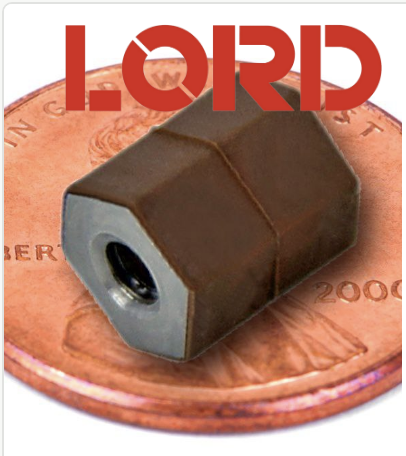

Micro-mounts™

Designed for sensitive electronic systems, Parker LORD Micro-mounts™ are capable of isolating electronic components and other light-weight electronics from shock and vibration.

Applying Parker LORD’s aerospace isolator knowledge, this unique series of miniature vibration isolators are high-performance isolators small enough and soft enough to protect individual electronic components allowing isolation at the circuit board level.

Micro-mounts can be used as a stand-alone solution or to augment performance of a Parker LORD full-system isolation solution. The small, flexible mounts are used successfully on GPS oscillators in satellites, military aircraft, downhole oil and gas equipment, and many more applications.

Made of Broad Temperature Range (BTR®) silicone bonded to stainless-steel, these miniature mounts are ideal for applications requiring consistent performance at extreme temperatures. The combination of this unique high-end silicone with stainless steel components assures easy installation in a wide range of applications.

How to select a vibration isolator

There are a number of critical pieces of information necessary to understand when choosing the appropriate isolator for a particular application. Some items are more critical than others, but all should be considered.

Weight, size, center-of-gravity of the equipment to be isolated

Types of dynamic disturbances to be isolated

Static loadings other than supported weight

Allowable system response

Ambient environment

Other environmental effects

Service life

One of the many benefits of being a Parker LORD Channel Partner is access to Parker LORD’s engineering support, their fully accredited test lab, and extensive design/analysis software capabilities. This computer capability, as well as specialized programs for analyzing engine/transmission combinations provides output to optimize performance over the complete range of operating speeds. Information needed to perform the analysis to facilitate design decisions using appropriate solutions includes:

Physical data – location relative to mounting points, sway space, maximum mounting size, resonance frequencies

Dynamics data – sinusoidal inputs, random inputs, shock requirement, sustained acceleration, vibration fragility envelope, dynamic coupling angle, desired returnability

Environmental data – operating and non-operating temperature, salt spray, humidity, sand and dust, fungus resistance, oil and/or gas

Case Study

Vertical Integration

Alleviates Production Delays

Learn more about how Signal Hound was able to overcome six months of production delays by finding a manufacturing partner that offered vertical integration.

Read the Case StudyChapter 5

Safety

There is one more thing to cover and that is understanding the importance of safety.

Yes, you can solve the vibration or shock with an isolator but sometimes the job does not stop there. Is the mount “safetied”? When the vibration mounts are the only thing supporting the entire piece of equipment, it’s crucial to ensure that the mount and/or the piece of equipment is secured by straps, webbing, washers, or other means to provide a “safetied” feature in the case that the rubber in the mount becomes damaged.

Sometimes the “safetied” feature is inherent to the mount as in the case of a Parker LORD safetied tubeform. These are designed to carry loads in both the axial and radial direction and uses only one washer on the bottom side.

Chapter 6

Next Steps

Well, as you can see there is a lot to know about vibration isolation and shock absorber; therefore, we recommend that you don’t go far without us!

It is always a smart decision to reach out to our vibration isolation experts to advise you while developing your design. Our engineers offer experience and expertise to help you determine potential vibration issues during product development and, more importantly, before the vibration issues actually occur in the field.

Are you experiencing vibration problems with products already deployed? Then it’s time to give us a call. With over 40 years of experience, we’ve likely seen it or solved it.

As a trusted Parker LORD channel partner for over 25 years, together Parker LORD and Modus® bring engineering and problem-solving skills directly to our customers. Use our expertise to help you specify appropriate high-performance rubber-to-metal bonded vibration isolators. Modus® adds further value by stocking the parts in Livermore, CA for immediate delivery! You can count on us so your customers can count on you.

Don't have time to read the entire guide now?

Fill out the form to get a downloadable PDF version of the guide to save so you can read it later.

Get Started

Speak to an Engineer Today

Don’t take our word for it. Reach out and speak to one of our engineers about your part today and see the benefits for yourself. We strive to turn all quotes around 48 hours or less to get your part moving as quickly as possible.

Submit a Design.png?width=1024&height=768&name=Telecommunciations%20(1).png)

.jpg?width=1200&height=627&name=_high%20electrical%20conductance%20thermal%20control%20coating%20(1).jpg)