Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Certification Requirements: AS9100 Rev D certification serves as the baseline quality management system for missile defense component suppliers, with ITAR registration and CMMC Level 2 or 3 compliance becoming increasingly mandatory for contractors working on classified systems

- Precision Standards: Interceptor components demand manufacturing tolerances of ±0.010" (±0.25 mm) for CNC-machined metallic components, with mission-critical parts requiring even tighter specifications and comprehensive documentation

- Security Framework: CMMC Level 3 compliance requires advanced cybersecurity controls to protect Controlled Unclassified Information (CUI), including network segmentation, multi-factor authentication, and continuous monitoring systems

- Material Specifications: MIL-STD specifications govern material selection and testing requirements, ensuring components can withstand extreme operational environments from -55°C to 125°C (-67°F to 257°F)

- Supply Chain Qualification: Missile Defense Agency (MDA) contractors must demonstrate vertical integration capabilities, engineering expertise, and robust quality systems to support rapid prototyping and production timelines where delays can impact national security

The Stakes of Missile Defense Manufacturing

Missile defense systems stand between populated areas and incoming threats. When these systems fail, the consequences extend beyond mission failure. Lives hang in the balance.

Component suppliers in this space operate under extraordinary pressure. The parts they manufacture must perform flawlessly in environments that would destroy commercial-grade components. There's no margin for error when interceptor components must function perfectly at hypersonic speeds.

Read the Guide to CMMC Level 2 and DFARS 252.204-7012 here!

Understanding Modern Missile Defense Architecture

The U.S. missile defense infrastructure relies on multiple integrated systems. Each system requires thousands of precision-engineered components that must meet exacting specifications.

Command and Control Systems (C2BMC)

Command, Control, Battle Management, and Communications (C2BMC) serves as the nervous system of the entire defense network. This system coordinates multiple sensor networks and weapons systems simultaneously. The electronic components that enable this coordination demand exceptional EMI shielding and thermal management solutions to maintain signal integrity in extreme conditions.

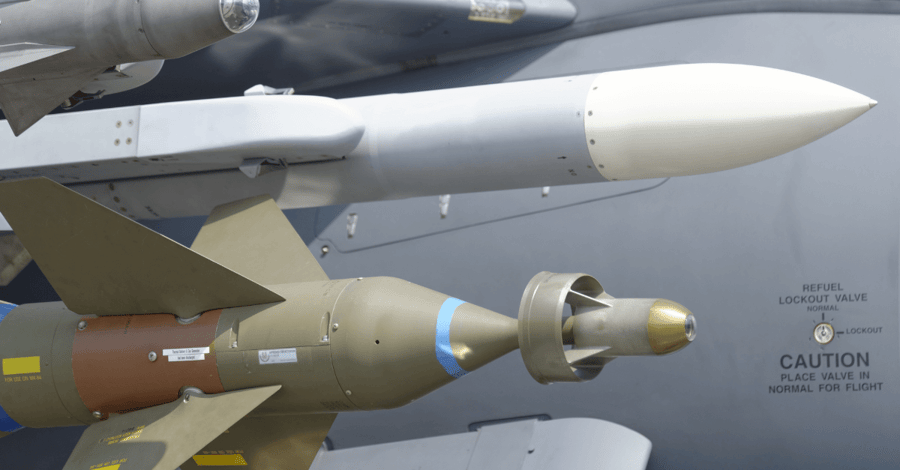

Patriot Advanced Capability-3 (PAC-3)

Patriot Advanced Capability-3 (PAC-3) interceptors represent the front line of tactical ballistic missile defense. These kinetic kill vehicles rely on precision guidance systems housed in aerodynamic enclosures that must maintain structural integrity during high-G maneuvers. The gaskets and seals protecting these guidance systems operate in temperature ranges from -40°C to 85°C (-40°F to 185°F) while maintaining perfect environmental sealing.

Terminal High Altitude Area Defense (THAAD)

Terminal High Altitude Area Defense (THAAD) systems engage threats in the terminal phase of flight. Components for THAAD interceptors must withstand the thermal shock of high-altitude interception while maintaining dimensional stability. RF shielding components in particular require specialized manufacturing processes to ensure consistent performance across the operational envelope.

Next Generation Interceptor (NGI)

Next Generation Interceptor (NGI) programs push the boundaries of what's possible in missile defense technology. These advanced systems demand manufacturing capabilities that didn't exist five years ago. Suppliers must demonstrate the ability to prototype rapidly while maintaining the quality standards required for production deployment.

Quality Management Systems: AS9100 Rev D Requirements

AS9100 Rev D certification forms the foundation of aerospace and defense quality management. This standard extends ISO 9001 requirements with aerospace-specific controls that address the unique challenges of defense manufacturing.

Configuration Management and Traceability

The configuration management requirements in AS9100 Rev D ensure that every component can be traced from raw material to final assembly. This traceability becomes critical when a component failure analysis requires reviewing every step of the manufacturing process. Suppliers must maintain records of material certifications, process parameters, inspection results, and operator qualifications for every part produced.

Risk Management and FMEA

Risk management processes under AS9100 Rev D require suppliers to identify potential failure modes before they occur. Failure Mode and Effects Analysis (FMEA) documentation must address not just manufacturing risks, but also risks related to supply chain disruption, obsolescence, and environmental factors. These analyses inform contingency planning and help ensure continuous supply even during geopolitical disruptions.

First Article Inspection Requirements

First Article Inspection (FAI) requirements demand comprehensive dimensional verification and material testing before production begins. For missile defense components, FAI reports typically include:

Dimensional Verification:

- CMM inspection results for all critical features

- Surface finish measurements using profilometry

- Geometric dimensioning and tolerancing (GD&T) verification

- Material composition analysis via spectroscopy

Performance Validation:

- Environmental stress screening results

- Thermal cycling test data

- Vibration and shock testing documentation

- Functional performance across operational temperature ranges

The corrective action process in AS9100 Rev D extends beyond fixing immediate problems. Root cause analysis must identify systemic issues that could affect other products or processes. When a nonconformance occurs in a missile defense component, the investigation often reveals opportunities for process improvement that benefit the entire operation.

Security and Export Control Framework

ITAR registration represents the minimum threshold for working with defense contractors. The International Traffic in Arms Regulations govern the export and temporary import of defense articles and services on the United States Munitions List (USML).

ITAR Compliance for Missile Defense

Missile defense components fall squarely under USML Category IV (Launch Vehicles, Guided Missiles, Ballistic Missiles, Rockets, Torpedoes, Bombs, and Mines). Suppliers must implement physical security measures that prevent unauthorized access to technical data and hardware. This includes secure storage areas, visitor access controls, and employee screening procedures.

CMMC Level 2 Requirements

CMMC Level 2 compliance addresses the protection of Controlled Unclassified Information (CUI) with documented policies and procedures. At this level, suppliers must demonstrate:

Access Control Measures:

- Multi-factor authentication for all system access

- Role-based access controls limiting CUI exposure

- Automated session termination after periods of inactivity

- Regular access reviews and recertification

Audit and Accountability:

- Comprehensive logging of CUI access and modifications

- Protected audit logs that cannot be altered

- Regular audit log reviews by security personnel

- Alert generation for suspicious activities

CMMC Level 3 for Advanced Systems

CMMC Level 3 requirements elevate security controls to address Advanced Persistent Threats (APTs). The distinction between Level 2 and Level 3 centers on the sophistication of threat actors and the value of the information being protected. NGI programs and other next-generation systems typically require Level 3 compliance.

Network segmentation at Level 3 isolates CUI environments from general business networks. This segmentation extends to physical infrastructure, with dedicated hardware for processing classified information. Intrusion detection systems monitor network traffic patterns to identify potential breaches before data exfiltration occurs.

Manufacturing Precision for Interceptor Components

The precision requirements for missile defense components exceed those found in most aerospace applications. Interceptor components must maintain dimensional stability across extreme temperature variations while withstanding shock loads during launch and interception.

CNC Machining Tolerances

CNC-machined housings for guidance systems typically require standard tolerances of ±0.010" (±0.25 mm). However, mating surfaces and critical alignment features often demand tolerances of ±0.005" (±0.127 mm) or tighter. Achieving these tolerances consistently requires:

Manufacturing Process Controls:

- Temperature-controlled machining environments at 20°C ±1°C (68°F ±1.8°F)

- Regular calibration of measurement equipment traceable to NIST standards

- Statistical process control with real-time monitoring

- First-piece inspection protocols for every production run

Form-in-Place Gasket Precision

Form-in-place gasket applications in missile defense components require exceptional precision. The standard tolerance of ±0.006" (±0.15 mm) for FIP beads ensures consistent compression and reliable sealing across the operational temperature range.

Conductive gasket materials used for EMI shielding must maintain their electrical properties across temperature extremes. Silver-nickel filled silicone compounds typically offer volume resistivity of 0.005 Ohm-cm with shielding effectiveness exceeding 100 dB across the frequency spectrum relevant to guidance systems.

Standard Manufacturing Tolerances

The table below outlines typical manufacturing tolerances for common missile defense component types:

Component Type | Standard Tolerance | Tighter Tolerance Available | Application Considerations |

CNC-Machined Housings | ±0.010" (±0.25 mm) | ±0.005" (±0.127 mm) | Critical alignment features may require tighter tolerances; longer lead times and increased costs apply |

FIP Gasket Beads | ±0.006" (±0.15 mm) | ±0.003" (±0.076 mm) | Tighter tolerances necessary for high-frequency RF shielding applications |

Die-Cut Gaskets (Dense Materials) | ±0.015" (±0.38 mm) for dimensions under 1.0" | ±0.010" (±0.25 mm) | Material selection and die design affect achievable tolerances |

±0.16 mm (±0.006") for 0-10 mm dimensions | ±0.10 mm (±0.004") | Precision molds and process control enable tighter tolerances for critical sealing applications |

Creative engineering solutions can achieve tolerances beyond these standard ranges. However, tighter tolerances should only be specified when design requirements truly demand them. Unnecessarily tight tolerances drive up costs and extend lead times without adding functional value.

Material Specifications and MIL-STD Requirements

MIL-STD specifications establish baseline material properties and testing protocols. These standards ensure that components perform reliably regardless of which qualified supplier manufactures them.

MIL-DTL-83528 for EMI Shielding Materials

MIL-DTL-83528 governs conductive elastomeric materials used for EMI/RFI shielding. This specification defines test methods for volume resistivity, shielding effectiveness, compression set, and environmental resistance.

Materials must demonstrate stable electrical properties after exposure to:

- Thermal aging: 1000 hours at 125°C (257°F)

- Thermal shock: -55°C to 125°C (-67°F to 257°F), 10 cycles

- Salt spray: 500 hours per ASTM B117

- Fluid resistance: Fuel, hydraulic fluid, and cleaning solvent exposure

MIL-STD-810 Environmental Testing

MIL-STD-810 environmental engineering considerations guide component design and testing. Method 514.8 addresses vibration exposure during ground transportation and flight operations. Missile defense components must survive vibration profiles that far exceed those found in commercial applications.

Temperature cycling per Method 503.7 validates component performance across operational temperature ranges. The test profile typically includes:

- High temperature exposure: 85°C (185°F) for 4 hours

- Rapid transition: Temperature change rate of 10°C/minute (18°F/minute)

- Low temperature exposure: -40°C (-40°F) for 4 hours

- Number of cycles: Minimum 10, often extending to 100 for critical components

Altitude Testing Requirements

Altitude testing under Method 500.6 ensures that components function properly in low-pressure environments. Interceptors may experience altitudes exceeding 30 km (100,000 feet) during flight. Outgassing of materials at these altitudes can contaminate optical systems or interfere with electrical connections.

Supplier Qualification and Continuous Improvement

The Missile Defense Agency and prime contractors maintain approved supplier lists. Achieving and maintaining qualification requires demonstrating consistent performance over time.

Initial Qualification Assessment

Initial qualification assessments evaluate:

Technical Capabilities:

- Manufacturing process documentation and control plans

- Quality management system implementation

- Engineering resources and design support capabilities

- Test equipment inventory and calibration systems

Past Performance:

- Delivery metrics from previous aerospace/defense programs

- Quality history and corrective action effectiveness

- Ability to scale from prototype to production volumes

- Financial stability and business continuity planning

Vertical Integration Advantages

Vertical integration capabilities provide significant advantages in missile defense manufacturing. Suppliers who can machine housings, dispense gaskets, apply protective coatings, and assemble sub-components reduce supply chain complexity. This integration eliminates handoffs between vendors that introduce opportunities for delays and quality issues.

Engineering Resources and DfM Support

Engineering resources matter more in defense applications than in commercial manufacturing. Suppliers with engineering staff comprising more than 10% of their workforce can provide Design for Manufacturability (DfM) feedback that prevents costly redesigns. These engineers understand how design choices affect manufacturing complexity, quality risk, and production costs.

Continuous improvement programs drive competitive advantage in defense manufacturing. Statistical process control data reveals trends before they result in nonconformances. Proactive process adjustments maintain tight control limits and minimize variation.

Frequently Asked Questions About Missile Defense Component Manufacturing

What certifications are required for missile defense contractors?

Missile defense contractors require AS9100 Rev D certification as the baseline quality standard, ITAR registration for handling defense articles, and CMMC Level 2 or 3 compliance for protecting Controlled Unclassified Information. ISO 9001 certification provides the foundation, while AS9100 Rev D adds aerospace-specific requirements.

What are standard manufacturing tolerances for interceptor components?

Standard manufacturing tolerances for missile defense interceptor components are ±0.010" (±0.25 mm) for CNC-machined housings and ±0.006" (±0.15 mm) for form-in-place gasket beads. Critical alignment features may require tighter tolerances of ±0.005" (±0.127 mm), though this increases costs and lead times.

What is the difference between CMMC Level 2 and Level 3?

CMMC Level 2 focuses on documented cybersecurity practices protecting CUI, while CMMC Level 3 implements advanced controls defending against Advanced Persistent Threats (APTs). Level 3 requires network segmentation, dedicated hardware for classified information, and intrusion detection systems monitoring for potential breaches.

Which MIL-STD specifications apply to missile defense components?

Key MIL-STD specifications for missile defense include MIL-DTL-83528 for conductive elastomeric materials, MIL-STD-810 Method 514.8 for vibration testing, Method 503.7 for temperature cycling, and Method 500.6 for altitude testing. These standards ensure components survive extreme operational environments.

How long does supplier qualification take for MDA contractors?

Supplier qualification timelines for Missile Defense Agency contractors vary based on certification status and past performance. Companies with existing AS9100 Rev D and ITAR compliance can complete initial assessments in 3-6 months. New suppliers requiring certification may need 12-18 months to achieve full qualification status.

Modus Advanced: Engineering Excellence in Defense Manufacturing

Modus Advanced serves missile defense contractors who demand precision, speed, and unwavering quality. Our AS9100 Rev D, ITAR, and ISO 9001 certifications establish the baseline. Our commitment to continuous improvement and engineering excellence sets us apart.

We currently hold CMMC Level 2 certification and maintain active progress toward CMMC Level 3 compliance because we understand the security challenges our partners face. Protecting your technical data and intellectual property isn't just a regulatory requirement. It's a fundamental aspect of the trust you place in us.

Our vertically integrated processes cover CNC machining, form-in-place gasket dispensing, waterjet cutting, die cutting, and assembly operations. This integration allows us to compress timelines that would take weeks with traditional supply chains into days. When missile defense programs require rapid prototyping or emergency production support, our capabilities respond to the urgency.

Engineering support drives every project we undertake. Our staff includes degree-holding engineers who specialize in manufacturability analysis, materials selection, and process optimization. These engineers review your designs before production begins, identifying opportunities to improve quality, reduce costs, and accelerate delivery.

Quality systems built around Six Sigma methodologies ensure consistent results. We don't just inspect quality into parts. We design processes that prevent defects from occurring. Our goal of 99.5% quality rate and 99.5% on-time delivery reflects our commitment to your mission success.

The Critical Path Forward

Missile defense component manufacturing demands more than technical competence. It requires understanding the stakes involved and maintaining unwavering focus on quality and security.

The gap between qualified suppliers and those merely claiming capability continues to widen. As missile defense systems become more sophisticated, the manufacturing requirements grow more stringent. Suppliers who invest in certifications, quality systems, and engineering talent position themselves as partners rather than vendors.

National security depends on the reliability of every component in the defense network. When you select a manufacturing partner for missile defense applications, you're choosing an ally in protecting lives. Choose partners who understand what's at stake and who have demonstrated the commitment to excellence that these applications demand.