Phase Change Materials for Advanced Thermal Management in Defense, Medical, and Aerospace Engineering

August 22, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Temperature regulation precision: Phase change materials provide consistent temperature control by absorbing and releasing thermal energy during state transitions at precisely defined temperatures

- Mission-critical reliability: Advanced PCM formulations deliver predictable thermal performance in extreme environments where conventional cooling methods fail

- Space and weight optimization: PCM-based thermal management systems offer superior energy density compared to traditional active cooling solutions, critical for aerospace and portable medical applications

- Passive operation advantages: Phase change materials function without external power requirements, enhancing system reliability in defense and emergency medical scenarios

- Material customization capabilities: Engineering teams can select from organic, inorganic, and eutectic PCM formulations to match specific operational temperature ranges and thermal capacity requirements

What Are Phase Change Materials? The Foundation of Advanced Thermal Control

Phase change materials are substances that absorb and release substantial amounts of thermal energy during solid-liquid phase transitions while maintaining nearly constant temperatures. This fundamental property makes PCMs invaluable for thermal management applications where precise temperature control is essential for mission success.

The principle behind phase change materials lies in latent heat storage. When a PCM reaches its melting point, it absorbs significant thermal energy without a corresponding temperature increase until the phase transition completes. This isothermal behavior provides exceptional temperature stability precisely when and where it's needed most in critical systems.

Thermal energy storage using phase change materials offers energy densities significantly higher than conventional sensible heat storage materials. While traditional materials store energy through temperature changes, PCMs store energy through molecular restructuring during phase transitions, providing superior performance for space-constrained applications.

Read the Complete Engineer's Guide to Thermal Management

Understanding Phase Change Material Classifications and Properties

Phase change materials encompass three primary categories serving different engineering applications. Organic PCMs include paraffins and fatty acids, offering chemical stability and non-corrosive properties ideal for electronics cooling. Inorganic PCMs encompass salt hydrates and metallic alloys, providing higher thermal conductivity and energy density for demanding applications. Eutectic mixtures combine multiple compounds to achieve specific melting points and optimized thermal properties.

Material selection for phase change materials requires systematic evaluation of thermal, physical, and chemical properties against application requirements. Engineers must consider operating temperature ranges, thermal cycling stability, and compatibility with containment materials under anticipated operating conditions.

The selection process begins with defining operational temperature ranges and thermal load profiles specific to the mission requirements.

PCM Category | Temperature Range (°C) | Thermal Conductivity (W/m·K) | Primary Applications |

Organic Paraffins | -10 to 80 | 0.2 - 0.3 | Electronics cooling, comfort systems |

Salt Hydrates | 10 to 100 | 0.4 - 0.8 | Building thermal regulation, solar storage |

Metallic Alloys | 60 to 400 | 10 - 50 | High-temperature aerospace applications |

-30 to 200 | 0.3 - 2.0 | Customized thermal management solutions |

Defense Applications: Mission-Critical Thermal Solutions

Defense systems operate in extreme environments where thermal management failures can compromise mission success and personnel safety. Phase change materials provide passive cooling solutions that function reliably without external power or complex mechanical systems that could fail in combat scenarios.

Electronic warfare equipment generates substantial heat loads while requiring precise temperature control for optimal performance. Phase change materials integrated into equipment enclosures absorb thermal spikes during high-power operations while maintaining component temperatures within specified limits for sustained operational capability.

Portable communication systems benefit from PCM thermal regulation during extended field operations. The passive nature of phase change materials eliminates the need for fans or active cooling systems that consume battery power and create detectable acoustic signatures in tactical environments.

Vehicle-mounted systems face particularly challenging thermal environments in armored platforms. Phase change materials can buffer temperature fluctuations where conventional HVAC systems may be compromised or unavailable during mission operations.

Key considerations for defense PCM applications include:

- Operational temperature ranges: Materials must function across extreme ambient conditions from arctic to desert environments spanning -40°C to +60°C (-40°F to +140°F)

- Mechanical durability: PCM containment systems must withstand shock, vibration, and impact loads typical of military operations according to MIL-STD specifications

- Chemical compatibility: Phase change materials must not degrade or contaminate sensitive electronic components over extended service life

- Maintenance requirements: Systems should operate without regular servicing or replacement in forward deployment scenarios

Medical Device Innovation Through PCM Integration

Medical devices increasingly rely on phase change materials to maintain critical temperatures for patient safety and device functionality. Temperature-sensitive medications, diagnostic equipment, and life support systems all benefit from precise thermal control that can mean the difference between life and death.

Portable medical devices face unique thermal challenges in emergency and field applications. Phase change materials provide temperature buffering that extends operational time without external power sources, critical for emergency medical services and disaster response scenarios where grid power is unavailable.

Laboratory equipment requires stable temperatures for accurate diagnostic results that directly impact patient care decisions. PCM-based thermal management systems maintain consistent sample temperatures during transport and analysis, ensuring measurement reliability and diagnostic accuracy.

Surgical instruments and implantable devices benefit from PCM thermal regulation during sterilization and operation. The predictable thermal behavior of phase change materials helps maintain sterile conditions while protecting temperature-sensitive components from thermal damage.

Medical PCM applications must address specific regulatory and safety requirements:

- Biocompatibility standards: Materials must meet FDA requirements for potential patient contact scenarios

- Sterilization compatibility: PCM systems must withstand repeated sterilization cycles without performance degradation

- Temperature precision: Medical applications often require tight temperature control within ±1°C (±1.8°F) tolerances

- Fail-safe operation: Systems must maintain safe temperatures even during power failures or equipment malfunctions

Aerospace Engineering: Weight-Critical Thermal Management

Aerospace applications demand maximum thermal performance per unit weight and volume. Phase change materials excel in these constrained environments by providing superior energy density compared to traditional thermal management approaches, essential for mission success.

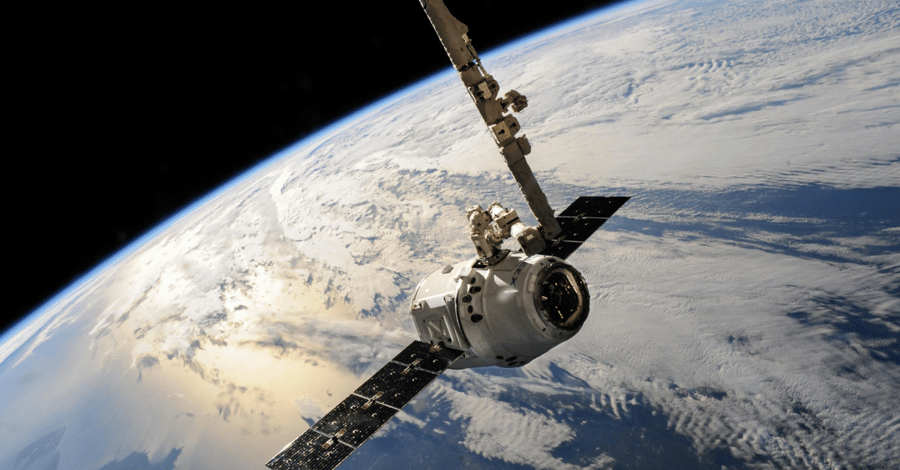

Satellite thermal control systems utilize phase change materials to manage orbital temperature cycling between eclipse and solar exposure phases. The extreme temperature variations experienced during orbital operations require robust thermal buffering capabilities that only PCMs can provide efficiently.

Aircraft avionics systems generate concentrated heat loads in confined spaces where weight and volume constraints severely limit cooling options. PCM integration provides passive thermal regulation without the complexity and weight penalties of active cooling systems that reduce payload capacity.

Spacecraft electronics must function reliably in the vacuum of space where conventional convective cooling is impossible. Phase change materials provide thermal inertia that smooths temperature variations and protects sensitive components during critical mission phases.

Aerospace PCM implementations focus on several critical performance parameters:

- Specific energy density: Maximum thermal storage capacity per unit mass, typically measured in kJ/kg for optimal spacecraft efficiency

- Thermal cycling endurance: Ability to withstand thousands of melt-freeze cycles without property degradation over mission lifetime

- Vacuum compatibility: Materials must not outgas or create contamination in space environments per NASA specifications

- Temperature range optimization: PCM selection must match specific mission thermal profiles and component operating ranges

Aerospace Application | Typical PCM Temperature Range (°C) | Key Performance Requirements |

Satellite thermal control | -20 to 60 | High thermal conductivity, vacuum stability |

Avionics cooling | 40 to 85 | Low outgassing, electrical isolation |

Spacecraft electronics | -40 to 80 | Radiation resistance, long-term stability |

Engine bay thermal management | 80 to 200 | High temperature stability, corrosion resistance |

Material Selection and Engineering Considerations

Selecting appropriate phase change materials requires systematic evaluation of thermal, physical, and chemical properties against application requirements. The decision process begins with defining operational temperature ranges and thermal load profiles for specific mission requirements.

Thermal conductivity significantly impacts PCM system performance and heat transfer rates. Pure phase change materials often exhibit low thermal conductivity, requiring enhancement through additives or structural modifications to achieve adequate heat transfer rates for time-critical applications.

Containment design represents a critical engineering challenge for PCM systems. The volume expansion that occurs during phase transitions must be accommodated without compromising system integrity or creating safety hazards in pressurized environments.

Chemical compatibility assessment ensures long-term system reliability over expected operational lifetimes. Phase change materials must not react with containment materials, adjacent components, or environmental contaminants over the expected service life.

Engineering teams should evaluate these essential material characteristics:

- Melting point accuracy: PCM transition temperature must align precisely with target thermal control requirements within ±2°C (±3.6°F)

- Latent heat capacity: Higher values provide more thermal storage per unit volume but may require different containment strategies

- Thermal conductivity: Enhanced formulations may be necessary for rapid heat transfer applications

- Viscosity characteristics: Liquid-phase viscosity affects heat transfer and containment design requirements

- Corrosion potential: Compatibility with aluminum, steel, and polymer containment materials must be verified through testing

- Cycling stability: Materials must maintain properties through thousands of thermal cycles without degradation

Integration Strategies and System Design

Successful PCM integration requires careful attention to heat transfer mechanisms and system architecture optimization. The relatively low thermal conductivity of many phase change materials necessitates enhancement strategies to achieve acceptable response times for mission-critical applications.

Heat transfer enhancement techniques include metallic additives, foam inserts, and finned structures that increase effective thermal conductivity. Research shows that graphene additives can improve thermal conductivity by up to 164%, while these approaches must balance improved heat transfer against increased system weight and complexity.

Encapsulation methods protect PCM materials while accommodating volume changes during phase transitions. Flexible containers, expansion chambers, and pressure relief mechanisms prevent containment failure during thermal cycling operations.

System integration considerations extend beyond the PCM material itself to include mounting methods, thermal interfaces, and integration with existing cooling systems. Proper thermal interface design ensures efficient heat transfer between heat sources and PCM storage volumes.

Effective PCM system design addresses several key integration challenges:

- Heat transfer optimization: Maximizing thermal conductivity through material selection and structural enhancements using carbon additives

- Volume change accommodation: Designing containment systems that handle 10-15% volume expansion during melting without structural failure

- Thermal interface design: Ensuring efficient heat transfer between components and PCM storage volumes with minimal thermal resistance

- System monitoring: Implementing temperature sensing and diagnostic capabilities for mission-critical applications

- Maintenance accessibility: Designing systems that allow inspection and potential replacement of PCM materials during service life

Performance Optimization and Testing Protocols

Phase change material systems require comprehensive testing to validate performance under realistic operating conditions. Standard laboratory tests may not capture the complex thermal environments encountered in defense, medical, and aerospace applications.

Thermal cycling tests evaluate long-term material stability and performance retention over operational lifetimes. These tests subject PCM samples to repeated melting and solidification cycles while monitoring thermal properties and physical integrity according to industry standards.

Accelerated aging protocols assess chemical stability and compatibility under elevated temperature and humidity conditions. These tests help predict long-term system reliability and identify potential failure modes before deployment.

Performance validation requires measurement of key thermal parameters under controlled conditions. Differential scanning calorimetry (DSC) provides precise measurement of melting points, latent heat capacity, and thermal transitions with laboratory accuracy.

Critical testing protocols for PCM systems include:

- Thermal cycling endurance: 1,000+ cycles minimum for critical applications, with property monitoring throughout test duration

- Accelerated aging: Elevated temperature exposure equivalent to 10+ years of service life under operational conditions

- Chemical compatibility: Long-term exposure testing with containment materials and environmental contaminants

- Mechanical integrity: Vibration and shock testing under conditions representative of intended applications

- Thermal performance mapping: Heat transfer rate measurements across expected operating conditions

Test Parameter | Measurement Method | Acceptance Criteria |

Melting point stability | DSC analysis | ±2°C (±3.6°F) deviation maximum |

Latent heat retention | Calorimetry measurement | >95% of initial value after cycling |

Thermal conductivity | Steady-state measurement | <10% degradation over service life |

Chemical compatibility | Mass spectroscopy analysis | No detectable contamination products |

Partnering with Advanced Manufacturing Expertise

The successful implementation of phase change material systems requires expertise in precision manufacturing, thermal analysis, and system integration. Complex PCM applications demand manufacturing partners who understand both material science fundamentals and practical engineering challenges.

Modus Advanced brings together engineering expertise and advanced manufacturing capabilities to support PCM system development from concept through production. Our team of engineers — comprising more than 10% of our staff — provides design support that ensures manufacturability while optimizing thermal performance for mission-critical applications.

Our AS9100 and ISO 9001 certifications demonstrate our commitment to quality standards essential for defense, medical, and aerospace applications. ITAR compliance enables us to support sensitive defense programs requiring secure handling of technical data and components.

The vertical integration of our manufacturing processes enables rapid prototyping and production of PCM containment systems, thermal interfaces, and integrated assemblies. This comprehensive capability reduces development timelines while maintaining strict quality control throughout the manufacturing process.

When your thermal management challenges require the precision and reliability that lives depend on, partner with a manufacturing team that understands the critical nature of your applications. Contact Modus Advanced to discuss how our engineering expertise and manufacturing capabilities can accelerate your next phase change material system development.