Tight Tolerance Manufacturing: Processes and Quality Control for Precision Engineering

September 19, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Precision Definition: Tight tolerance manufacturing achieves dimensional accuracy within ±0.010" (±0.25 mm) or tighter, requiring specialized processes and rigorous quality control systems

- Process Selection: Advanced CNC machining, precision grinding, and EDM form the foundation of tight tolerance capabilities in modern machine shops

- Quality Systems: Comprehensive metrology, environmental controls, and statistical process control ensure consistent micron-level precision across production runs

- Design Considerations: Engineers must balance tolerance requirements with manufacturability, material properties, and cost implications when specifying components

- Industry Applications: Medical devices, aerospace components, and defense systems demand tight tolerance manufacturing to ensure reliability in mission-critical applications

Understanding Tight Tolerance Manufacturing

Tight tolerance manufacturing represents the pinnacle of precision engineering, where dimensional accuracy becomes critical for component performance and system reliability. This specialized approach achieves tolerances significantly tighter than standard industrial practices, often reaching micron-level precision.

definition

What is Tight Tolerance Manufacturing?

Tight tolerance manufacturing is a specialized precision process that maintains dimensional accuracy within extremely narrow limits — typically ±0.010" (±0.25 mm) or tighter — using advanced equipment, environmental controls, and rigorous quality systems.

Learn MoreThe definition varies across industries but generally refers to tolerances of ±0.010" (±0.25 mm) or tighter. In aerospace and medical applications, tolerances may reach ±0.001" (±0.025 mm) or even tighter for critical components where lives depend on perfect performance.

Read the Complete Guide to Machining Tolerances here!

Advanced Manufacturing Processes for Precision Components

Achieving tight tolerances requires sophisticated manufacturing processes that go far beyond conventional machining capabilities. These specialized techniques combine advanced equipment, precise tooling, and expert operator knowledge to consistently produce components within micron-level specifications.

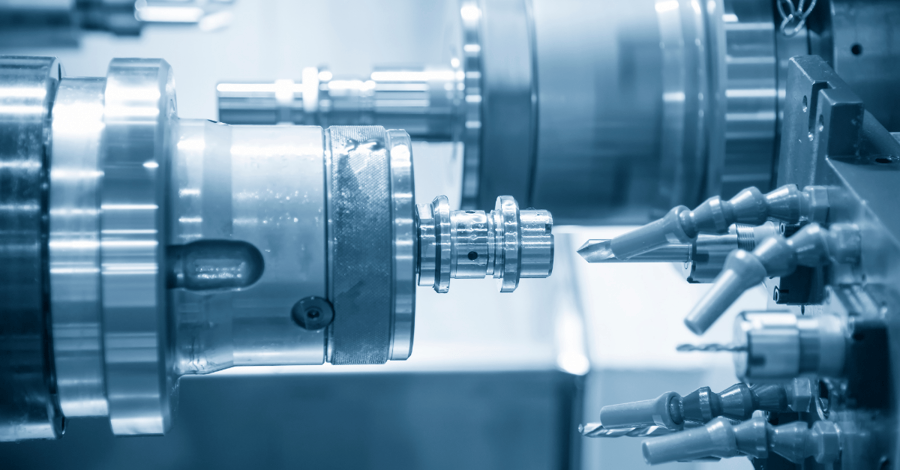

CNC Machining: The Foundation of Precision

Computer numerical control (CNC) machining serves as the cornerstone of tight tolerance manufacturing in most precision machine shops. Modern CNC systems combine precise mechanical motion with sophisticated software control to achieve repeatable accuracy across complex geometries.

High-precision CNC machining centers incorporate advanced spindle systems that maintain exceptional rotational accuracy. Precision linear guides and ball screws ensure consistent positioning within tight specifications. Temperature compensation systems automatically adjust for thermal expansion, maintaining accuracy as machines warm during operation.

CNC Machining Capabilities | Standard Tolerance | Achievable Precision |

General Machining | ±0.010" (±0.25 mm) | ±0.001" (±0.025 mm) |

High-Precision Centers | ±0.005" (±0.127 mm) | ±0.0005" (±0.013 mm) |

Micro-Machining | ±0.002" (±0.051 mm) | ±0.0001" (±0.0025 mm) |

Precision Grinding and EDM Operations

Grinding processes excel at achieving surface finishes and dimensional tolerances that surpass conventional machining capabilities. Surface grinding can achieve flatness tolerances of ±0.0001" (±0.0025 mm) across large surface areas through controlled abrasion.

Electrical Discharge Machining (EDM) enables creation of complex geometries with tight tolerances in materials difficult to machine conventionally. Wire EDM achieves tolerances of ±0.0001" (±0.0025 mm) while creating intricate internal features. The EDM process removes material through controlled electrical discharges, allowing stress-free machining that doesn't alter material properties.

Quality Control Systems and Metrology

Tight tolerance manufacturing demands quality control systems that exceed the precision of the manufacturing processes themselves. These comprehensive measurement and inspection capabilities ensure every component meets exacting specifications through advanced metrology equipment and rigorous process monitoring.

Measurement and Inspection Technologies

Tight tolerance manufacturing demands measurement capabilities that exceed the precision of manufacturing processes themselves. Coordinate measuring machines (CMMs) provide accuracy and repeatability necessary for verifying micron-level tolerances across complex three-dimensional geometries.

Modern CMMs incorporate advanced probe systems that measure internal features, complex contours, and surface textures with exceptional accuracy. Temperature-controlled measurement environments ensure thermal expansion doesn't compromise measurement accuracy. Software automation enables rapid inspection of multiple features across production runs.

Essential Quality Control Equipment:

- Coordinate Measuring Machines (CMMs): Primary dimensional verification with ±0.0001" (±0.0025 mm) accuracy

- Optical Measurement Systems: Laser interferometry for precise distance measurements

- Surface Profilometers: Surface texture and roughness verification

- Environmental Controls: Temperature stability within ±1°C (±1.8°F)

Statistical Process Control Implementation

Statistical process control (SPC) transforms measurement data into actionable insights that drive continuous improvement. Control charts track key dimensional characteristics over time, identifying trends before they result in nonconforming parts.

Process capability studies quantify the relationship between process variation and tolerance requirements. Cpk values above 1.33 indicate processes capable of consistently producing parts within specification. Real-time monitoring systems alert operators to developing problems before they result in scrapped parts.

Environmental Controls and Manufacturing Stability

Environmental factors significantly impact the ability to maintain tight tolerances throughout the manufacturing process. Temperature variations, vibrations, and air quality all influence dimensional accuracy, making controlled manufacturing environments essential for consistent precision results.

Temperature and Vibration Management

Thermal stability plays a crucial role in maintaining tight tolerances throughout manufacturing. Temperature variations cause material expansion and contraction that can easily exceed tight tolerance requirements. Modern tight tolerance machine shops maintain temperature control within ±1°C (±1.8°F) or tighter.

Mechanical vibrations from nearby equipment can compromise precision manufacturing operations. Effective vibration isolation requires comprehensive analysis of vibration sources and transmission paths. Machine foundations incorporate isolation materials and structural design elements that minimize vibration transmission.

Critical Environmental Factors:

- Temperature Control: ±1°C (±1.8°F) facility-wide with localized machine controls

- Humidity Management: Controlled moisture levels to prevent dimensional changes

- Vibration Isolation: Active and passive systems for critical equipment

- Air Quality: Filtered environments to prevent contamination

Manufacturing Tolerance Standards and Capabilities

The foundation of tight tolerance manufacturing rests on understanding standard capabilities and when tighter tolerances become necessary. Standard CNC machining tolerances of ±0.010" (±0.25 mm) serve as the baseline for most precision applications.

Process | Standard Tolerance | Achievable Precision | Typical Applications |

CNC Machining | ±0.010" (±0.25 mm) | ±0.001" (±0.025 mm) | General precision parts |

Surface Grinding | ±0.0005" (±0.013 mm) | ±0.0001" (±0.0025 mm) | Critical flat surfaces |

Wire EDM | ±0.0002" (±0.005 mm) | ±0.00005" (±0.001 mm) | Complex hard materials |

Cylindrical Grinding | ±0.0002" (±0.005 mm) | ±0.00005" (±0.001 mm) | Precision shafts, bores |

Tighter tolerances require specialized approaches that increase both lead times and manufacturing costs. Engineers should specify tight tolerances only when design function truly demands this level of precision.

Industry-Specific Applications and Requirements

Different industries have unique requirements that drive the need for tight tolerance manufacturing. Understanding these sector-specific demands helps engineers appreciate when micron-level precision becomes essential for component functionality and safety.

Medical Device Manufacturing

Medical device components often require tight tolerances to ensure proper function and patient safety. Surgical instruments demand precise dimensions for proper fit and operation. Implantable devices require dimensional accuracy for biocompatibility and long-term performance.

Regulatory requirements add complexity to tight tolerance work. FDA Quality System Regulation (QSR) and ISO 13485 standards demand comprehensive documentation and process validation beyond traditional manufacturing quality systems.

Aerospace and Defense Applications

Aerospace components operate in extreme environments where dimensional accuracy directly impacts safety and mission success. Engine components require tight tolerances for proper clearances and thermal expansion management. Structural elements demand precision for load distribution and fatigue life.

Defense applications involve specialized materials and coating requirements that complicate tight tolerance manufacturing. ITAR compliance adds security considerations, requiring controlled access and documentation procedures.

Cost Considerations and Design Guidelines

Tight tolerance manufacturing involves significant cost implications that must be balanced against functional requirements. Understanding these economic factors and design principles helps engineers make informed decisions about when to specify tight tolerances.

Balancing Precision and Economics

Tight tolerance manufacturing typically costs 2-5 times more than standard processes due to specialized equipment requirements, extended cycle times, and additional quality control measures. The increased cost results from specialized tooling, longer cycle times, additional inspection steps, and higher scrap rates during development.

Why does tight tolerance manufacturing cost more? Specialized equipment requirements, extended cycle times, additional quality control measures, more precise tooling, and higher scrap rates typically make tight tolerance manufacturing 2-5 times more expensive than standard tolerances.

Value engineering approaches help optimize the balance between tolerance requirements and manufacturing costs. Analyzing functional requirements of each dimension can identify opportunities to relax tolerances without compromising performance.

Design for Manufacturability Guidelines

- Tolerance Allocation: Use statistical analysis to identify critical dimensions requiring tight control

- Material Selection: Consider thermal expansion coefficients and machinability characteristics

- Geometric Dimensioning: Apply GD&T principles for clear communication of design intent

- Stack-Up Analysis: Evaluate how individual tolerances combine to affect assembly performance

Quality Certifications and Industry Standards

Tight tolerance manufacturing requires robust quality management systems that ensure consistent results across all production activities. AS9100 certification demonstrates aerospace industry compliance, while ISO 9001 provides the foundation for quality management across industries.

Medical device manufacturing demands additional certifications and process validations. FDA registration and ISO 13485 compliance provide frameworks for consistent, traceable production of medical components.

Frequently Asked Questions About Tight Tolerance Manufacturing

What tolerances are considered "tight" in manufacturing?

Tight tolerances typically refer to dimensional accuracy within ±0.010" (±0.25 mm) or tighter, with ultra-precision applications achieving tolerances as tight as ±0.001" (±0.025 mm) or micron-level precision.

Which industries require tight tolerance manufacturing?

Medical devices, aerospace, defense, automotive, and electronics industries rely heavily on tight tolerance manufacturing for components where precision directly impacts safety, performance, and reliability.

How much does tight tolerance manufacturing cost compared to standard manufacturing?

Tight tolerance manufacturing typically costs 2-5 times more than standard tolerances due to specialized equipment, extended cycle times, additional quality control measures, and higher precision tooling requirements.

What equipment is required for tight tolerance manufacturing?

Advanced CNC machining centers, precision grinding equipment, EDM machines, coordinate measuring machines (CMMs), and climate-controlled environments are essential for achieving and maintaining tight tolerances.

The Future of Precision Manufacturing

Tight tolerance manufacturing continues evolving with advances in machine tool technology, measurement systems, and process control methods. Additive manufacturing technologies are beginning to achieve precision levels that approach conventional machining for specific applications.

Artificial intelligence and machine learning applications promise to revolutionize process optimization and quality control. These technologies identify subtle patterns in process data that human operators might miss, enabling proactive adjustments that maintain quality and reduce waste.

Engineers working with tight tolerance requirements benefit from partnering with manufacturers such as Modus Advanced, who understand the critical nature of precision work and invest in capabilities necessary for consistent results. When lives depend on component reliability — whether in medical devices, aerospace systems, or defense applications — tight tolerance manufacturing provides the precision foundation that enables innovation and saves lives.