custom manufacturing services

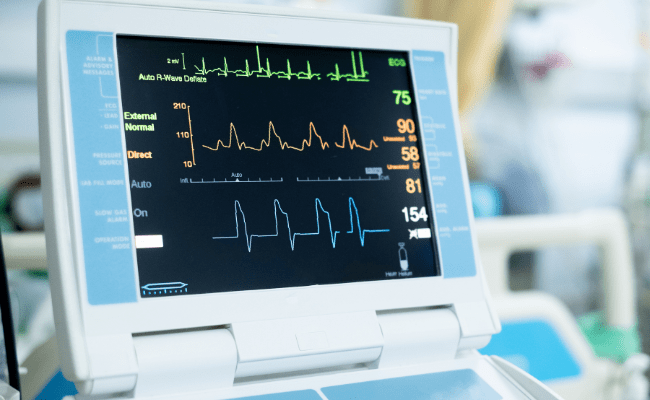

Custom Medical Device Manufacturing

Your Partner in Building Precision Medical Solutions

Accelerating your ability to bring tomorrow's life-saving innovations to market through custom manufacturing expertise.

Submit a DesignModus by the Numbers

Your Dedicated Custom Medical Device Manufacturing Partner

We've built deep expertise in custom medical device manufacturing through diverse projects including:

- Dialysis equipment

- Ventilators

- Heart pumps, like Left Ventricular Assist Devices

- Oxygenators

- Resuscitators

- Robotic surgical equipment

Hundreds of Medical Device Manufacturing Customers

With a wealth of long-term custom manufacturing partnerships, we understand your specialized needs.

CustomersDecades of Manufacturing Excellence

For over 30 years, Modus has provided custom manufacturing solutions, evolving alongside medical technology advancements.

Our CompanyScale + Specialized Manufacturing Scope

Our engineering team supports custom medical device manufacturing from rapid prototyping to full-scale production.

Engineering SupportProduct Lifecycle

Custom Manufacturing Support Across Your Product Lifecycle

From Prototype Through Production Manufacturing

The shift from prototype to production demands flexibility - as your needs evolve from rapid iteration to assembly efficiency and cost optimization, our custom manufacturing capabilities adapt accordingly.

Design

Critical DFM feedback that prevents costly redesigns while ensuring your parts perform as intended.

Prototype

Get precision prototypes rapidly, allowing you to validate your design without delay.

Rapid Iteration

As your design evolves, we quickly implement changes between iterations while providing technical feedback to enhance performance.

Long Term Production

When your design is finalized, we transition to optimized manufacturing processes that maintain quality while maximizing efficiency at scale.

Design

Critical DFM feedback that prevents costly redesigns while ensuring your parts perform as intended.

Learn moreModus Engineering Team

Our engineering-heavy staffing ensures technical expertise is embedded in every step of your manufacturing process. With engineers making up over 10% of our team, we provide superior design guidance and manufacturing solutions that other converters simply cannot match.RetryClaude can make mistakes. Please double-check responses.

Learn morePrototype

Get precision prototypes rapidly, allowing you to validate your design without delay.

Learn moreDie Cutting

Convert raw materials into precise components with our die cutting capabilities that deliver consistent quality at production volumes.

Learn moreWaterjet Cutting

Cut complex shapes from virtually any material with precision waterjet technology that maintains material integrity without heat-affected zones.

Learn moreCNC Cutting

Achieve precision cuts with minimal waste using computer-controlled cutting that translates your exact specifications into perfect components every time.

Learn moreCNC Machining

Transform your designs into precision-machined components with tight tolerances, complex geometries, and superior surface finishes, delivered with shorter lead times.

Learn moreFIP Dispensing

Create perfect custom gaskets with our automated dispensing technology that places material precisely where needed—even on the most complex and intricate designs.

Learn morePrototype

Get precision prototypes rapidly, allowing you to validate your design without delay. Then, work with our team to iterate on your design until it is perfect.

Learn moreProcess 1

Access any of our core manufacturing processes in any order to produce a completed component.

Learn moreProcess 2

Access any of our core manufacturing processes in any order to produce a completed component.

/manufacturing-processesProcess 3

Access any of our core manufacturing processes in any order to produce a completed component.

/manufacturing-processesProcess 4

Access any of our core manufacturing processes in any order to produce a completed component.

/manufacturing-processesCNC Machining

Transform your designs into precision-machined components with tight tolerances, complex geometries, and superior surface finishes, delivered with shorter lead times.

Learn morePlating + Coating

Enhance durability, conductivity, thermal properties and corrosion resistance with specialized surface treatments that meet your exact performance specifications.

Learn moreFIP Dispensing

Create perfect custom gaskets with our automated dispensing technology that places material precisely where needed—even on the most complex and intricate designs.

Learn moreDie Cutting

Convert raw materials into precise components with our die cutting capabilities that deliver consistent quality at production volumes.

Learn moreWaterjet Cutting

Cut complex shapes from virtually any material with precision waterjet technology that maintains material integrity without heat-affected zones.

Learn moreCNC Cutting

Achieve precision cuts with minimal waste using computer-controlled cutting that translates your exact specifications into perfect components every time.

Learn moreLaminating & Slitting

Transform flexible materials into custom components engineered to your exact specifications with our advanced soft goods converting capabilities.

Learn moreO-Ring Splicing

Produce custom-sized o-rings and d-rings for perfect fit in your application.

Learn moreMedical-Grade Manufacturing Standards

Quality and Precision Define Our Manufacturing DNA

Our years in custom medical device manufacturing have built robust quality processes and infrastructure needed to deliver materials converted to your exact specifications.

- AS 9100

- ISO 9001

- ITAR

- CMMC

CFR Class 6 Silicones

Our CFR Class 6 silicones meet all regulatory requirements for human contact while maintaining excellent properties for custom medical device manufacturing.

USP Class 6 Silicones

USP Class 6 silicones provide biocompatible solutions for critical custom-manufactured medical components requiring tissue contact.

FDA Approved Materials

Our FDA approved materials deliver regulatory compliance alongside optimal performance for custom medical device manufacturing applications.

Chemical Resistant Materials

Specialized materials engineered to withstand multiple sterilization cycles while maintaining critical performance in custom medical device components.

Case Study

Custom Manufacturing Solution for Medical Device Assembly

Learn how Modus' custom manufacturing expertise solved assembly issues, enabling a medical device company to accelerate time-to-market.

See HowCustom Manufacturing Capabilities

Comprehensive Solutions for Medical Device Manufacturers

Our breadth of manufacturing capabilities makes us an ideal partner for custom medical device projects from prototype to production. Simply bring us a design and volume requirements, and we'll recommend the optimal manufacturing process.

SigShield: Turnkey RF Sub-Assemblies

Get completed RF shields from a single custom manufacturing source: machining, FIP dispensing, plating, coating, and assembly of converted materials.

Learn More

Die Cutting

Convert raw materials into precise custom components with our die cutting capabilities that deliver consistent quality for medical device production volumes.

Learn More

Form-in-Place Dispensing

Create perfect custom gaskets with automated dispensing technology that places material precisely—even on the most complex medical device designs.

Learn More

EMI + RF Shielding

Protect sensitive medical electronics with precision-engineered custom shielding solutions that maintain signal integrity in demanding healthcare environments.

Learn More

CNC & Digital Cutting

Achieve precision cuts with minimal waste using computer-controlled cutting that translates exact specifications into perfect custom medical components.

Learn More

CNC Machining

Transform designs into precision-machined custom medical components with tight tolerances, complex geometries, and superior surface finishes.

Learn More

Platings & Coatings

Enhance durability, conductivity, and corrosion resistance with specialized surface treatments for custom medical device manufacturing.

Learn More

Thermal Management

Control heat transfer precisely with advanced thermal interface materials that enhance performance in custom-manufactured medical devices.

Learn More

Sound Dampening

Reduce unwanted noise and vibration with acoustically engineered materials for custom medical device applications.

Learn More

Soft-Goods Converting

Transform flexible materials into custom medical components engineered to your exact specifications with advanced converting capabilities.

Learn More

Custom Gasket Manufacturing

Get custom-engineered gaskets designed specifically for your medical device's unique requirements, manufactured with tight tolerances.

Learn More

Waterjet Cutting

Cut complex shapes from virtually any material with precision waterjet technology that maintains material integrity for custom medical components.

Learn More

Vibration Isolation

Protect sensitive medical components from harmful vibrations with custom isolation systems designed for demanding healthcare environments.

Learn More

Microwave & RF Absorption

Eliminate signal reflections with precision-engineered absorber materials for custom medical device applications.

Learn More

Risk Reduction

We De-risk Your Custom Medical Device Manufacturing

Our team, process, and infrastructure are built to minimize risk throughout the custom manufacturing process, saving time and cost while building lasting partnerships.

- US-based medical device manufacturing supply chain

- Concurrent manufacturing processes

- Shorter lead times for custom medical components

Get Started

Speak with a Custom Medical Device Manufacturing Engineer Today

Experience our expertise firsthand. Connect with one of our engineers about your custom medical device needs and see the benefits of partnering with Modus. We strive to deliver all manufacturing quotes within 48 hours to accelerate your medical innovation.

Submit a Design