Biocompatible Conductive Gasket Materials for Implantable Devices

July 9, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Implantable medical devices require conductive gasket materials that meet both electrical performance and biocompatibility requirements

- Material selection must balance conductivity, sealing properties, and long-term compatibility with human tissue

- FDA regulatory compliance (ISO 10993) is mandatory for all materials in implantable devices

- Specialized conductive gasket materials like platinum-cured silicones and medical-grade fluorosilicones offer optimal solutions for different implant environments

- Material testing and validation is a critical step in the design process, requiring both electrical and biological performance verificatiom

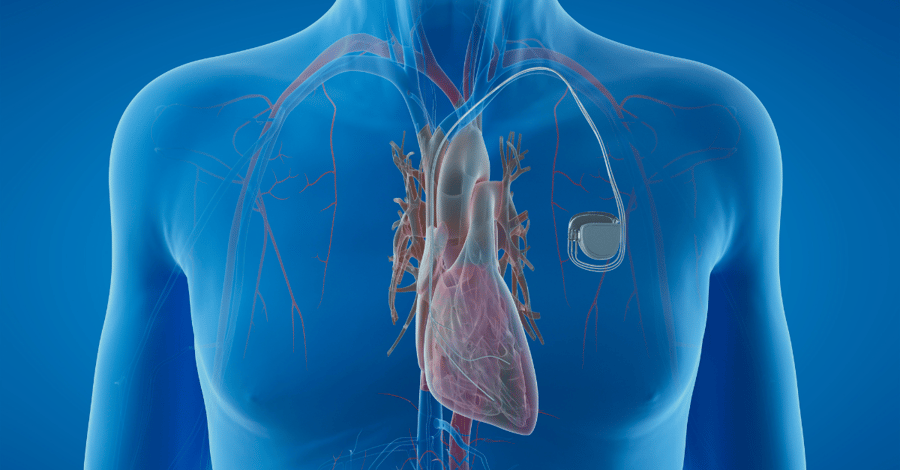

Medical device engineers face a unique challenge when developing implantable technologies. The human body presents one of the harshest environments for electronic components – conductive, humid, warm, and filled with reactive chemicals and cells designed to attack foreign objects. When your device must function flawlessly for years inside this environment, material selection becomes critical.

Conductive gasket materials serve dual purposes in implantable devices. They provide electromagnetic interference (EMI) shielding to protect sensitive electronics and can help with basic environmental sealing that protect components from bodily fluids. The wrong material choice can lead to device failure, patient harm, or both.

Understanding Biocompatibility Requirements for Implantable Materials

Before diving into specific conductive gasket materials, we must understand what "biocompatibility" actually means in the context of implantable devices.

definition

What is Biocompatibility?

Biocompatibility refers to a material's ability to perform its intended function without eliciting undesirable local or systemic effects in the host.

Learn MoreFor implantable devices, this involves a comprehensive evaluation across multiple parameters:

- Cytotoxicity - The material must not kill or damage cells in contact with it

- Sensitization - The material must not cause allergic reactions

- Irritation - The material must not cause inflammation or irritation

- Acute systemic toxicity - The material must not release harmful compounds into the body

- Subchronic toxicity - The material must remain safe over extended periods

- Genotoxicity - The material must not damage genetic material

- Implantation - The material must be evaluated for local effects after implantation

- Hemocompatibility - For blood-contacting devices, the material must not adversely affect blood

All conductive gasket materials used in implantable devices must undergo rigorous testing according to ISO 10993 standards and receive FDA approval. This significantly narrows the available material options compared to external medical devices.

Learn more about FDA approved materials for medical devices here.

Conductive Gasket Material Options for Implantable Applications

Several specialized conductive gasket materials have been developed specifically for implantable applications. Each offers different advantages depending on the specific requirements of your device.

Medical-Grade Silicone with Conductive Fillers

Platinum-cured silicone elastomers form the foundation of many biocompatible conductive gasket materials. This high-purity silicone material is cured using platinum catalysts rather than peroxide, resulting in fewer extractables and higher biocompatibility. These materials combine the excellent biocompatibility of medical-grade silicone with carefully selected conductive fillers.

The most common conductive fillers include:

- Silver-coated glass microspheres - Provide excellent conductivity with minimal impact on biocompatibility

- Gold-coated particles - Offer superior biocompatibility but at higher cost

- Platinum particles - Provide excellent conductivity and biocompatibility for critical applications

- Carbon nanotubes - Emerging option with excellent conductivity and potentially good biocompatibility (still undergoing extensive testing)

These silicone-based conductive gasket materials typically offer shore hardness ranges from 30 to 80 Shore A, allowing engineers to select the appropriate compression characteristics for their specific application. Shore hardness is a measure of the hardness of elastomeric materials, with higher values indicating harder materials. Temperature stability ranges from -55°C to 200°C (-67°F to 392°F), making them suitable for both normal body temperature operation and sterilization processes.

The silicone base provides excellent sealing properties against bodily fluids while the conductive fillers create paths for electrical continuity across the gasket. Volume resistivity – a measure of how strongly a material opposes the flow of electric current, expressed in ohm-centimeters (ohm-cm) – typically ranges from 0.001 to 0.1 ohm-cm depending on the filler type and concentration. Lower resistivity values indicate better conductivity.

Medical-Grade Fluorosilicone Composites

For implantable devices exposed to particularly harsh bodily fluids or requiring chemical resistance beyond what standard silicones can provide, medical-grade fluorosilicone composites offer an alternative solution.

These conductive gasket materials incorporate the chemical resistance of fluorosilicone with biocompatible conductive fillers. Key advantages include:

- Superior resistance to lipids and fatty acids

- Excellent stability in the presence of enzymes

- Enhanced resistance to oxidation in vivo

- Maintained properties during long-term implantation

Medical-grade fluorosilicone conductive gaskets typically operate in temperature ranges from -55°C to 175°C (-67°F to 347°F) and offer shore hardness values from 40 to 75 Shore A. Volume resistivity generally falls between 0.005 and 0.5 ohm-cm.

Specialized TPE Compounds

Thermoplastic elastomers (TPEs) engineered specifically for medical implants represent another category of conductive gasket materials. These materials combine the processing advantages of thermoplastics with the elastomeric properties needed for effective sealing.

Biocompatible TPE conductive gasket materials typically incorporate:

- Medical-grade polymer bases (such as SEBS or polyurethane)

- Carefully selected conductive fillers (often silver-coated glass or precious metals)

- Biocompatible processing aids and stabilizers

These materials offer shore hardness ranges from 50 to 90 Shore A and temperature stability from -40°C to 135°C (-40°F to 275°F). Volume resistivity typically falls between 0.01 and 1.0 ohm-cm.

Comparative Analysis of Implantable Conductive Gasket Materials

The table below provides a comparative analysis of the most common conductive gasket materials used in implantable medical devices:

Material Type | Volume Resistivity (ohm-cm) | Temperature Range | Shore Hardness | Key Advantages | Best Applications |

Platinum-cured silicone with silver-coated glass | 0.005-0.05 | -55°C to 200°C (-67°F to 392°F) | 30-70 Shore A | Excellent balance of properties, reliable track record | Cardiac devices, neurostimulators |

Platinum-cured silicone with gold particles | 0.001-0.01 | -55°C to 200°C (-67°F to 392°F) | 40-80 Shore A | Superior biocompatibility, highest conductivity | Critical long-term implants, brain interfaces |

Medical fluorosilicone composites | 0.005-0.5 | -55°C to 175°C (-67°F to 347°F) | 40-75 Shore A | Chemical resistance, stability in harsh environments | Digestive tract implants, drug delivery systems |

Medical TPE compounds | 0.01-1.0 | -40°C to 135°C (-40°F to 275°F) | 50-90 Shore A | Processing advantages, design flexibility | Orthopedic implants, temporary devices |

Carbon nanotube silicone composites | 0.01-0.1 | -55°C to 200°C (-67°F to 392°F) | 30-70 Shore A | Emerging technology, potential for enhanced properties | Currently in research/testing phase |

This comparison highlights the importance of selecting the appropriate conductive gasket material based on your specific implantable device requirements.

Critical Design Considerations for Implantable Conductive Gaskets

When selecting and implementing conductive gasket materials for implantable devices, several critical design factors must be considered:

Galvanic Compatibility

Implantable devices operate in a conductive electrolyte environment (bodily fluids), creating potential for galvanic corrosion between dissimilar metals. Galvanic corrosion is an accelerated corrosion process that occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (like bodily fluids). Your conductive gasket material selection must consider:

- The housing materials of your device

- Any exposed electrical contacts

- The specific bodily environment of implantation

- Expected device lifespan

Galvanic incompatibility can lead to accelerated corrosion, material degradation, and premature device failure. This is particularly critical for long-term implants where even slow corrosion processes can eventually compromise device integrity.

Compression Set and Long-Term Performance

Implantable devices must maintain their environmental seals and electrical continuity for their entire operational life, often years or decades. Conductive gasket materials must therefore exhibit:

- Low compression set (typically <20% after 70 hours at 100°C/212°F)

- Stable electrical properties over time

- Resistance to stress relaxation in vivo

- Maintained mechanical properties despite constant compression

Compression set refers to the permanent deformation remaining when a force applied to a gasket is removed, usually expressed as a percentage of the original deflection. The ideal conductive gasket material will maintain both its hermetic seal (a gas-tight seal that completely prevents the passage of air or fluids) and electrical conductivity throughout the device's intended lifespan without requiring maintenance (which is impossible for fully implanted devices).

Manufacturing and Sterilization Compatibility

The manufacturing and sterilization processes for implantable devices place additional requirements on conductive gasket materials. These materials must withstand:

- Sterilization methods (gamma radiation, ethylene oxide, autoclave)

- Cleaning processes

- Assembly procedures

- Any curing or post-processing steps

Incompatibility with manufacturing or sterilization processes can alter material properties, potentially compromising both biocompatibility and functional performance.

Form-in-Place (FIP) vs. Pre-Formed Gaskets for Implantable Applications

For implantable devices, engineers must choose between form-in-place (FIP) and pre-formed conductive gasket materials. Each approach offers distinct advantages and challenges.

Form-in-Place Conductive Gasket Materials

FIP technology allows for precise application of conductive gasket materials directly onto component surfaces. For implantable applications, this offers several advantages:

- Ability to create extremely small, precise gasket profiles

- Excellent adaptability to complex geometries

- Reduced assembly complexity

- Potentially enhanced reliability through elimination of joints

However, FIP conductive gasket materials for implantable applications face additional challenges:

- More complex biocompatibility validation due to the dispensing and curing processes

- Need for specialized dispensing equipment in cleanroom environments

- Additional process validation requirements

When selecting FIP conductive gasket materials for implantable devices, engineers must ensure both the uncured and cured materials meet biocompatibility requirements. The dispensing process must also avoid contamination that could compromise biocompatibility.

EMI shielding, the practice of reducing electromagnetic interference using barriers made of conductive materials, is a critical function of many conductive gaskets in implantable devices. FIP gaskets can be precisely designed to provide targeted EMI shielding exactly where needed while maintaining necessary biocompatibility.

Pre-Formed Conductive Gaskets

Pre-formed conductive gaskets offer a different set of advantages for implantable applications:

- Simpler process validation

- Potentially easier biocompatibility testing (material is in final form before assembly)

- Consistent performance across production runs

- Ability to pre-test gaskets before assembly

The challenges with pre-formed conductive gaskets include:

- Limitations in minimum size and complexity of geometry

- Potential for seal reliability issues at joints or corners

- More complex assembly processes

For many implantable devices, hybrid approaches using both pre-formed and FIP conductive gasket materials may provide optimal solutions, leveraging the advantages of each technology where most appropriate.

View the full Conductive Gaskets for Medical Device Shielding resource center.

Engineering Support in Material Selection and Testing

Selecting the optimal conductive gasket material for your implantable device requires balancing multiple competing requirements. Working with manufacturing partners who understand both electrical performance and biocompatibility concerns is essential.

Look for partners who can provide:

- Guidance on material selection based on your specific application

- Access to material specialists who understand implantable device requirements

- Testing capabilities for both electrical and mechanical properties

- Design for manufacturability (DFM) expertise specific to medical implants

Early engagement with manufacturing partners can help identify potential issues before they become costly design changes or regulatory delays.

Why Choose Modus Advanced for Your Implantable Device Components

At Modus Advanced, we understand that implantable devices aren't just technical challenges – they're life-changing innovations that patients will rely on every day. Our engineering-first approach ensures that we can help you select and implement the optimal conductive gasket materials for your specific application.

With more than 10% of our staff being engineers, we bring technical expertise to every project. Our comprehensive quality management system, including ISO 9001 certification, ensures that every component meets the exacting standards required for medical implants.

Our vertical integration capabilities allow us to handle multiple manufacturing processes under one roof, reducing lead times and ensuring consistent quality across all components. From material selection through prototyping and production, our team works with yours to accelerate your path to market without compromising on the quality that patients' lives depend on.

Because when it comes to implantable medical devices, one day matters. Each day sooner we can help you bring your life-changing innovation to market means one more day a patient can benefit from your technology.