Close Tolerance Precision Machining for Critical Applications

September 17, 2025

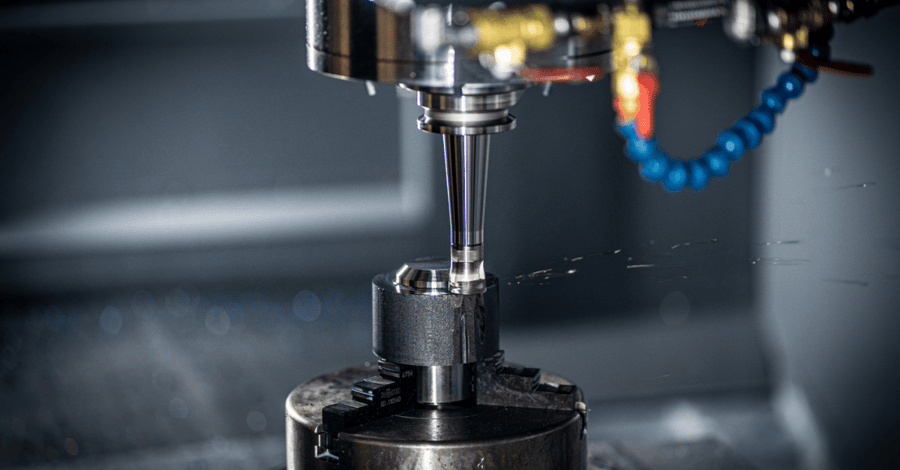

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Close tolerance precision machining achieves dimensional accuracy within ±0.010" (±0.25 mm) or tighter, essential for components where microscopic deviations can mean the difference between mission success and catastrophic failure

- Critical applications in medical devices, aerospace, defense, and space systems demand precision that goes beyond manufacturing capability — it requires understanding the life-or-death implications of every dimension

- Advanced CNC technology combined with rigorous quality control systems enables repeatable precision at the scale required for production volumes while maintaining zero-defect standards

- Material selection plays a crucial role in achieving close tolerances, with considerations including thermal expansion coefficients, machinability, and end-use environmental conditions

- Comprehensive inspection protocols using coordinate measuring machines (CMMs) and advanced metrology equipment ensure every dimension meets specification before components reach critical applications

In the operating room, a cardiac catheter must navigate arteries with clearances measured in fractions of millimeters. In aerospace applications, turbine components operate under extreme conditions where dimensional variations can trigger catastrophic failures. Defense systems require components that perform flawlessly when lives hang in the balance.

These scenarios demand more than standard manufacturing precision. They require close tolerance precision machining — a specialized discipline where engineering expertise meets advanced manufacturing technology to create components that meet the most demanding specifications.

Close tolerance machining serves industries where failure is not an option. Medical device manufacturers rely on precision machining for life-saving equipment. Aerospace engineers depend on exact tolerances for flight safety systems.

definition

What is Close Tolerance Precision Machining?

Close tolerance precision machining refers to manufacturing processes that consistently achieve dimensional accuracies of ±0.010" (±0.25 mm) or tighter, along with specified surface finishes and geometric tolerances, across production volumes with statistical process control.

Learn MoreClose tolerance precision machining represents the intersection of advanced manufacturing capability and critical application requirements. Every dimension matters because the stakes are simply too high for anything less than perfection.

Read the Complete Guide to Machining Tolerances here!

What is Close Tolerance Precision Machining? Standards and Specifications

Close tolerance machining typically refers to manufacturing processes that consistently achieve dimensional accuracies within ±0.010" (±0.25 mm) or tighter. However, the definition extends beyond simple dimensional control to encompass surface finish requirements, geometric tolerances, and repeatability across production volumes.

Precision machining tolerances vary by application complexity. Standard close tolerance work maintains ±0.010" (±0.25 mm), while ultra-precision applications achieve ±0.002" (±0.05 mm) or tighter specifications.

definition

What are Geometric Tolerances?

Geometric tolerances control the form, orientation, and location of features independent of size dimensions, including specifications like flatness, perpendicularity, concentricity, and position that are critical for proper part function and assembly.

Learn MoreThe distinction between standard CNC machining and close tolerance work lies in the systematic approach to controlling every variable that affects final part dimensions. For truly critical applications, tolerances can extend to ±0.002" (±0.05 mm) or even tighter specifications.

These ultra-precise requirements demand:

- Specialized equipment: CNC machines with enhanced positioning accuracy and vibration isolation

- Enhanced process controls: Real-time monitoring systems that detect variations immediately

- Extensive quality validation: Statistical process control methods that ensure consistency across production volumes

- Environmental management: Temperature-controlled facilities that eliminate thermal expansion variables

Advanced Technologies Enabling Precision Machining Excellence

Modern close tolerance precision machining relies on sophisticated manufacturing systems that address every factor affecting dimensional accuracy. These technologies work together to create an integrated approach to precision manufacturing.

High-precision CNC machining centers form the foundation of close tolerance manufacturing. These systems incorporate advanced control algorithms and precision positioning capabilities essential for critical applications.

Key technological enablers include:

- High-precision CNC machining centers: Advanced control systems with thermal compensation that adjusts for temperature variations throughout production cycles

- Precision spindle systems: Advanced bearing designs that minimize runout and vibration, critical for achieving surface finish requirements

- Tool presetting systems: Consistent tool geometry and positioning that eliminates variables affecting dimensional accuracy

- Environmental controls: Temperature-controlled manufacturing environments maintained at 20°C (68°F) ±1°C to prevent thermal expansion during machining

- Real-time monitoring: Process variation detection systems that enable immediate corrective action before parts fall outside specification limits

definition

What is Thermal Compensation?

Thermal compensation involves automatic CNC system adjustments that account for thermal expansion and contraction of machine components, workpieces, and cutting tools during machining operations to maintain dimensional accuracy.

Learn MoreDefinition

What is Runout?

Runout refers to the deviation from perfect circular motion in rotating components like spindles, causing dimensional variations and surface finish problems that must be minimized in close tolerance applications.

Learn MoreThe integration of these technologies creates a manufacturing environment where precision is not accidental but systematically controlled. This proactive approach to quality control is essential for maintaining the consistency required in critical applications.

Material Considerations for Close Tolerance Applications

Material selection significantly impacts the achievability of close tolerances and long-term dimensional stability. Close tolerance machining requires understanding how different materials behave under precise manufacturing conditions.

Precision machining materials must meet specific criteria for thermal stability, machinability, and end-use performance. Material properties directly influence achievable tolerances and manufacturing approaches.

Material Properties Impact Table

Material Category | Thermal Expansion Coefficient | Machinability Rating | Typical Applications |

Aluminum Alloys | 23 × 10⁻⁶/°C | Excellent | Aerospace housings, medical devices |

Stainless Steel | 17 × 10⁻⁶/°C | Good | Surgical instruments, defense components |

Titanium Alloys | 8.6 × 10⁻⁶/°C | Challenging | Aerospace structures, medical implants |

Copper Alloys | 17 × 10⁻⁶/°C | Excellent | RF shielding, electrical components |

Critical material considerations for close tolerance machining include:

- Aluminum alloys: Excellent machinability with weight reduction benefits, but higher thermal expansion requires careful temperature control during machining

- Stainless steel: Superior corrosion resistance for medical applications, with work hardening challenges requiring optimized cutting parameters

- Titanium alloys: Outstanding strength-to-weight ratios with significant machining challenges due to work hardening and heat generation tendencies

- Copper alloys: Excellent electrical properties for RF applications with good machinability characteristics but thermal expansion considerations

Quality Control and Inspection for Precision Machining

Close tolerance precision machining demands inspection capabilities that match or exceed the precision of the manufacturing processes themselves. The measurement systems must provide resolution and accuracy that validates component specifications with absolute confidence.

Quality control in precision machining requires advanced metrology equipment and systematic inspection protocols. Measurement accuracy determines the reliability of close tolerance components in critical applications.

Advanced inspection technologies include:

- Coordinate measuring machines (CMMs): Accuracies of ±0.0001" (±0.0025 mm) or better for dimensional verification of complex geometries

- Laser interferometry systems: Non-contact measurement for critical dimensions without surface contact that could affect delicate components

- Surface profilometers: Quantitative surface finish validation ensuring texture requirements are met consistently

- Optical comparators: Complex geometric inspections for features difficult to measure with contact methods

- Statistical process control (SPC): Dimensional trend tracking that enables proactive adjustments to maintain process capability

Definition

What is Statistical Process Control?

Statistical process control (SPC) uses statistical methods to monitor and control manufacturing processes, tracking measurement data over time to identify trends and variations before they result in out-of-specification parts. Learn MoreStandard Tolerance Capabilities Table

Process Type | Standard Tolerance | Precision Tolerance | Ultra-Precision |

CNC Machining | ±0.010" (±0.25 mm) | ±0.005" (±0.13 mm) | ±0.002" (±0.05 mm) |

Surface Finish | 125 μin Ra | 63 μin Ra | 32 μin Ra |

Geometric Tolerance | ±0.010" (±0.25 mm) | ±0.005" (±0.13 mm) | ±0.002" (±0.05 mm) |

Repeatability | 99.7% within spec | 99.9% within spec | 99.95% within spec |

definition

What is Surface Finish Ra?

Surface finish Ra (arithmetic average roughness) measures the average deviation of surface peaks and valleys from the mean line, with lower Ra values indicating smoother surfaces critical for sealing, aesthetic, and functional requirements. Learn MoreTemperature-controlled inspection rooms eliminate environmental variables that could affect measurement accuracy. These facilities typically maintain temperature stability within ±0.5°C to ensure consistent measurement results across all inspection activities.

Industry-Specific Applications and Requirements

Critical applications across multiple industries depend on close tolerance precision machining for components where failure is not an option. Each industry presents unique challenges and requirements that drive manufacturing approaches.

Precision machining serves diverse industries with varying tolerance requirements. Medical devices demand biocompatible materials with exact dimensions. Aerospace applications require lightweight components with exceptional strength.

Medical Device Applications

Patient safety depends on exact dimensional control across multiple component categories:

- Surgical instruments: Precise fit and finish ensuring proper function during critical procedures

- Implantable devices: Biocompatibility requirements with dimensional accuracy over extended service life

- Diagnostic equipment: Precision components enabling accurate medical measurements and imaging

- Drug delivery systems: Exact flow control requiring precise internal geometries and surface finishes

Aerospace Applications

Performance under extreme conditions demands precision that withstands operational stresses:

- Engine components: Operation at temperatures exceeding 1000°C (1832°F) while maintaining precise clearances

- Structural components: Significant stress loads with strict weight optimization requirements

- Control surfaces: Exact aerodynamic profiles for flight performance and safety

- Landing gear systems: Precision bearings and actuators handling extreme loads during operation

Defense Systems

Reliable operation under combat conditions where failure threatens mission success:

- Precision-guided systems: Accurate targeting dependent on close tolerance components for reliable operation

- Communication systems: RF shielding components requiring precise dimensions for signal integrity maintenance

- Weapon systems: Components that must function flawlessly under extreme operational conditions

- Armor systems: Precision-fitted components providing protection while maintaining mobility

Space Applications

The ultimate critical system requirements with no possibility for maintenance or repair:

- Vacuum operation: Components functioning in space environment with extreme temperature cycling

- Zero-defect requirements: Every dimension perfect because there are no second chances for correction

- Extended mission life: Reliability over years of operation without maintenance intervention

- Weight optimization: Maximum performance with minimum mass for launch efficiency

Common Challenges in Close Tolerance Machining

Close tolerance precision machining presents several technical challenges that require systematic engineering solutions. Understanding these challenges and implementing appropriate solutions determines success in critical applications.

Manufacturing challenges in precision machining stem from multiple variables affecting dimensional accuracy. Temperature fluctuations, material properties, and equipment limitations create complexity requiring engineered solutions.

Common Manufacturing Challenges

- Machine tool thermal growth: Spindle and structural component expansion during operation affects dimensional accuracy

- Workpiece deflection: Clamping forces introduce dimensional variations, particularly in thin-walled components

- Tool wear progression: Surface finish and dimensional accuracy degradation over extended production runs

- Material stress relief: Dimensional changes after clamping force removal due to internal stress redistribution

Engineering Solutions

- Thermal compensation systems: Automatic CNC positioning adjustments maintaining accuracy throughout production runs

- Optimized fixturing design: Finite element analysis minimizing deflection while maintaining adequate workpiece restraint

- Tool monitoring systems: Cutting force and vibration signature tracking predicting replacement requirements before quality compromise

- Stress-relieving processes: Heat treatments and optimized machining sequences minimizing dimensional changes after processing

Frequently Asked Questions About Close Tolerance Precision Machining

What tolerances are achievable with close tolerance machining?

Close tolerance machining typically achieves ±0.010" (±0.25 mm) as standard, with precision applications reaching ±0.005" (±0.13 mm) and ultra-precision work achieving ±0.002" (±0.05 mm) or tighter.

What industries require close tolerance precision machining?

Medical devices, aerospace and defense systems, and space applications rely heavily on close tolerance precision machining for components where dimensional accuracy is critical for safety and performance.

How does material selection affect close tolerance machining?

Material properties including thermal expansion coefficients, machinability ratings, and work hardening characteristics directly influence achievable tolerances and manufacturing approaches in precision machining applications.

What inspection equipment is required for close tolerance work?

Coordinate measuring machines (CMMs) with ±0.0001" (±0.0025 mm) accuracy, laser interferometry systems, surface profilometers, and statistical process control systems ensure quality in close tolerance machining.

Selecting the Right Manufacturing Partner for Close Tolerance Work

Close tolerance precision machining requires more than advanced equipment — it demands engineering expertise, quality systems, and manufacturing experience specific to critical applications. The right partnership becomes essential for success in demanding applications.

Precision machining partnerships require careful evaluation of capabilities, certifications, and experience. Manufacturing partners must demonstrate proven success in similar critical applications.

Essential Partner Capabilities

- Appropriate certifications: AS9100 for aerospace quality system compliance, ISO 9001 for quality management principles

- Security clearances: ITAR registration enabling defense-related project work requiring controlled access

- Engineering support: Design for manufacturability reviews identifying potential issues before production begins

- Quality system capabilities: Statistical process control, advanced inspection equipment, and documented procedures

- Proven performance history: Documented success in similar critical applications with reference customers

Partnership Benefits

- Technical expertise: Engineering teams providing manufacturing process development for close tolerance components

- Integrated capabilities: Complete production under one roof reducing lead times while maintaining quality control

- Quality assurance: Systems and procedures ensuring consistent results across all production volumes

- Collaborative approach: Working partnership focused on long-term success rather than transactional relationships

At Modus Advanced, our engineering team represents more than 10% of our staff, providing the technical expertise required for close tolerance precision machining success. Our AS9100 and ISO 9001 certifications, combined with ITAR compliance, demonstrate our commitment to quality and security standards essential for critical applications.

Our vertically integrated capabilities enable complete component production under one roof, from initial machining through final inspection and quality validation. This integrated approach reduces lead times while maintaining the quality control essential for close tolerance work.

Engineering Excellence for Critical Applications

Close tolerance precision machining represents the marriage of advanced manufacturing technology with engineering expertise focused on applications where precision is not optional — it is essential for mission success and human safety.

The difference between standard manufacturing and close tolerance precision work lies in understanding the critical nature of every dimension and the systematic approach required to achieve consistent results. When lives depend on your innovation, precision becomes more than a specification — it becomes a responsibility.

Partner with a manufacturing team that understands what is at stake. Because when precision matters most, engineering excellence makes the difference between success and failure, between meeting specifications and saving lives.