Custom Manufacturers vs. Standard Suppliers: Making the Right Choice for Your Project

June 18, 2025

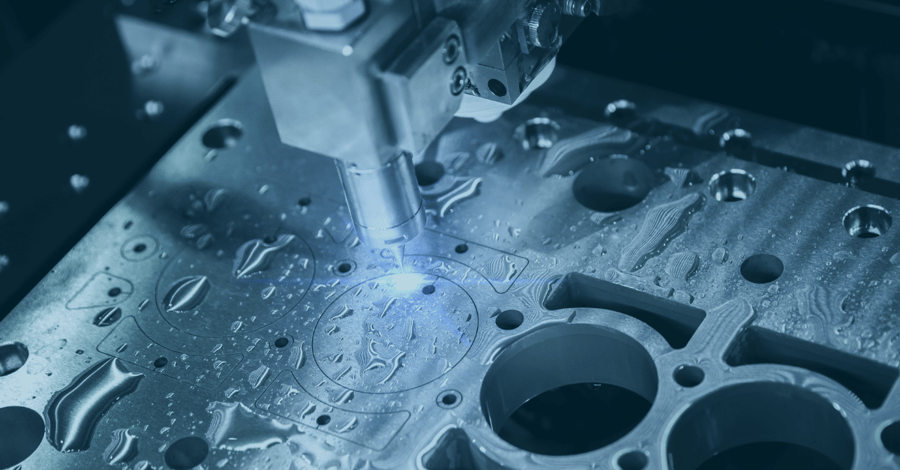

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Custom manufacturers provide tailored solutions for unique specifications and complex requirements, while standard suppliers offer off-the-shelf products with established performance characteristics

- Cost considerations differ significantly between options — custom manufacturers require higher upfront investment but may provide better long-term value for specialized applications

- Lead times for custom manufacturers typically range from weeks to months depending on complexity, while standard suppliers often provide immediate or short-term availability

- Quality control approaches vary substantially, with custom manufacturers offering design-specific validation while standard suppliers rely on established testing protocols

- Scalability requirements should drive your selection — custom manufacturers excel at adapting to changing volumes while standard suppliers optimize for consistent demand patterns

- Regulatory compliance capabilities become critical in aerospace, defense, and medical device applications where custom manufacturers often provide necessary industry expertise

Engineering teams face a fundamental decision when sourcing components for their projects. The choice between custom manufacturers and standard suppliers directly impacts product performance, project timelines, and budget allocation. This decision becomes particularly critical in aerospace, defense, and medical device applications where component specifications can determine mission success or patient safety.

Understanding the distinct advantages and limitations of each approach enables informed decision-making that aligns with your project's technical requirements and business objectives. For engineers developing mission-critical systems, this selection process requires careful analysis of how each option supports your product's unique requirements while maintaining the quality standards your applications demand.

Everything you need to know (and more!) about custom manufacturing services!

Understanding the Fundamental Differences

Custom manufacturers and standard suppliers represent two fundamentally different approaches to component sourcing, each optimized for specific types of projects and requirements.

DEFINITION

What Are Custom Manufacturers?

Custom manufacturers design and produce components according to client-specific requirements and specifications. These manufacturing partners work from your drawings, prototypes, or performance specifications to create components that meet your exact needs rather than adapting existing products.

definition

What Are Standard Suppliers?

Standard suppliers provide pre-designed, off-the-shelf components that have been developed for broad market applications. These suppliers maintain inventory of established products with documented specifications and proven performance characteristics.

Aspect | Custom Manufacturers | Standard Suppliers |

Design Control | Complete specification control | Limited to available options |

Development Time | Weeks to months | Immediate to days |

Initial Investment | Higher tooling/setup costs | Lower entry costs |

Volume Flexibility | Adaptable to requirements | Optimized for standard volumes |

Technical Support | Dedicated engineering resources | Application engineering support |

IP Protection | Client retains full ownership | Shared technology platform |

These fundamental differences create distinct advantages and considerations that must be evaluated against your specific project requirements. Industry research indicates that custom manufacturers typically focus on reducing waste and equipment costs while ensuring quick inventory turnover through just-in-time manufacturing approaches.

When Custom Manufacturers Excel

Custom manufacturers provide optimal solutions for projects with unique specifications, regulatory requirements, or performance demands that standard components cannot meet. Several project characteristics typically favor custom manufacturing approaches, including specific material properties, unusual geometries, or integration with proprietary systems.

Unique Specification Requirements

Custom manufacturers excel when your project demands specifications outside the range of standard components. For aerospace applications, components may require:

- Temperature resistance from -65°C to 200°C (-85°F to 392°F) or higher

- Specific electromagnetic shielding effectiveness ratings

- Weight optimization for flight applications

- Resistance to vibration, shock, and altitude variations

- Compliance with AS9100 and NADCAP requirements

Medical device applications often require biocompatible materials, sterilization compatibility, and FDA-approved material certifications that standard components may not provide. Research shows that custom manufacturers can implement specialized technologies and processes that serve specific market segments, enabling precision manufacturing that matches unique client specifications.

Complex Integration and Regulatory Requirements

Projects requiring tight integration between multiple components or systems frequently benefit from custom manufacturers' approaches. These partners can optimize interfaces, reduce assembly complexity, and improve overall system performance through design integration.

Industries with strict regulatory requirements often find that standard components lack necessary certifications or documentation. Custom manufacturers specializing in regulated industries understand compliance requirements and maintain appropriate quality systems and certifications. According to aerospace industry data, custom manufacturers with ITAR registration and AS9100 certification provide essential capabilities for defense and aerospace applications.

See our ITAR and AS9100 certifications here!

When Standard Suppliers Are the Right Choice

Standard suppliers provide optimal solutions for projects where proven performance, rapid availability, and cost efficiency take priority over customization. Many successful projects leverage standard components effectively by designing around available products rather than requiring custom solutions.

Proven Performance and Rapid Deployment

Standard suppliers excel when your project can utilize components with established performance characteristics and field-proven reliability. Benefits include:

- Extensive testing and validation data available

- Field failure data and reliability statistics

- Established supply chains and manufacturing processes

- Multiple sourcing options for supply security

- Lower technical risk through proven performance

Projects with aggressive timelines often benefit from standard supplier relationships that provide immediate component availability. Standard suppliers maintain inventory and can often ship components within days rather than the weeks or months required for custom manufacturers. Industry studies demonstrate that standard suppliers excel in cost efficiency, speed, and standardization for high-volume applications.

Cost-Sensitive and Non-Critical Applications

Standard suppliers typically provide lower per-unit costs through economies of scale and established manufacturing processes. Projects with tight budget constraints or high-volume requirements often find standard components more economically viable.

Components that do not directly impact core product performance or safety may be excellent candidates for standard solutions, allowing engineering resources to focus on custom manufacturers where they provide the greatest value.

Comprehensive Cost Analysis Framework

Cost considerations between custom manufacturers and standard suppliers extend beyond simple unit pricing to include development costs, inventory requirements, and long-term total cost of ownership. Custom manufacturers typically require higher upfront investment but may provide better long-term value for specialized applications.

Investment Comparison Analysis

Cost Category | Custom Manufacturers | Standard Suppliers |

Development | $5,000 - $50,000+ | $0 - $5,000 |

Tooling | $10,000 - $100,000+ | $0 |

First Article | $1,000 - $10,000 | $0 |

Unit Cost | Variable by volume | Fixed pricing tiers |

Modification | Lower incremental cost | Full redevelopment |

Note: Cost ranges vary significantly based on component complexity and manufacturing processes required.

The economic crossover point between custom manufacturers and standard suppliers depends heavily on production volumes and component specifications. Total cost of ownership analysis should include factors beyond initial component pricing, such as supply chain control, modification costs, and lifecycle management. Manufacturing cost analysis reveals that custom manufacturers often become more cost-effective at higher volumes due to optimized manufacturing processes and reduced material waste.

Lead Time and Availability Factors

Lead time requirements significantly influence the choice between custom manufacturers and standard suppliers. Lead time differences can range from days to months depending on component complexity and manufacturing requirements.

Custom manufacturers require development time for design, prototyping, and validation that standard suppliers eliminate through existing products. This development phase typically ranges from 4-16 weeks depending on component complexity. Once development is complete, custom manufacturers may provide competitive production lead times, particularly for specialized components.

Standard suppliers can often provide samples within days and production quantities within 2-4 weeks, assuming inventory availability. However, custom manufacturers often provide greater flexibility for schedule changes and volume adjustments once manufacturing processes are established.

Quality Control and Validation Approaches

Quality control methodologies differ substantially between custom manufacturers and standard suppliers, each offering distinct advantages for different application requirements.

Learn more about our process here!

Custom Manufacturer Quality Systems

Custom manufacturers develop quality control processes specifically for your component requirements, including:

- Component-specific testing procedures

- Design for manufacturability (DFM) feedback

- Process optimization for your specifications

- Dedicated engineering support for quality issues

- Traceability systems tailored to your requirements

Standard Supplier Validation

Standard suppliers provide extensive validation data from established testing protocols and field experience, including:

- Extensive field performance data

- Established testing protocols and procedures

- Multiple validation sources and applications

- Statistical performance databases

- Regulatory compliance documentation

Aerospace, defense, and medical device applications require specialized quality approaches that may favor one option over the other based on specific compliance requirements. Quality management studies show that custom manufacturers provide unmatched control and customization opportunities for quality validation processes.

Scalability and Volume Considerations

Production volume requirements significantly influence the optimal choice between custom manufacturers and standard suppliers. Custom manufacturers often provide more favorable pricing and service for low-volume applications where standard suppliers may impose minimum order quantities or premium pricing.

Custom manufacturers offer advantages including no minimum order quantity constraints, flexible production scheduling, prototype-to-production continuity, and design modification capability. Standard suppliers typically excel at high-volume production through established manufacturing processes and supply chain optimization.

Projects with unpredictable demand patterns may benefit from custom manufacturers' relationships that provide greater volume flexibility compared to standard suppliers who may require volume commitments.

Strategic Decision Framework

Selecting between custom manufacturers and standard suppliers requires systematic evaluation of your project's technical requirements, business objectives, and strategic priorities.

Evaluation Criteria | Favors Custom Manufacturers | Favors Standard Suppliers |

Specification uniqueness | High | Low |

Volume requirements | Variable | Predictable |

Timeline urgency | Low | High |

Budget flexibility | Higher | Lower |

Technical risk tolerance | Higher | Lower |

Regulatory complexity | High | Low |

Innovation requirements | High | Low |

The quality of your supplier relationship often determines project success regardless of whether you choose custom manufacturers or standard suppliers. Evaluate potential partners based on their technical capabilities, quality systems, and collaborative approach. Partnership evaluation research emphasizes the importance of selecting partners who can meet stringent quality standards and commit to trustworthy, reliable long-term relationships.

Visit the full resource center on all custom manufacturing services.

Industry-Specific Considerations for Mission-Critical Applications

Aerospace, defense, and medical device industries require specialized approaches that significantly influence the choice between custom manufacturers and standard suppliers.

Aerospace and Defense Requirements

For aerospace and defense applications, custom manufacturers must demonstrate:

- AS9100 and ITAR compliance capabilities

- Experience with specialized materials and extreme operating conditions

- Traceability and documentation requirements for mission-critical applications

- Security protocols for sensitive technology protection

Medical Device Compliance

Medical device applications require custom manufacturers with:

- ISO 13485 quality systems designed for medical device production

- Biocompatible material expertise and FDA validation support

- Clean room manufacturing capabilities for sterile device production

- Post-market surveillance and regulatory compliance documentation

Industry compliance data confirms that custom manufacturers specializing in regulated industries provide superior compliance capabilities compared to standard suppliers who may lack necessary certifications.

Technology Integration and Innovation Opportunities

Custom manufacturers typically invest in specialized technologies that serve specific market segments while standard suppliers focus on technologies that provide broad market applications. This distinction becomes critical for companies pursuing innovative product development strategies.

Custom manufacturers often provide earlier access to emerging manufacturing technologies and materials that may not yet be available through standard supplier channels. They can implement process innovations specifically for your components while standard suppliers typically cannot modify established production processes for individual customers.

Frequently Asked Questions About Custom Manufacturers vs. Standard Suppliers

Q: How do I know if my project needs custom manufacturers or standard suppliers?

A: Evaluate your specification uniqueness, volume requirements, timeline constraints, and regulatory compliance needs using the decision framework provided above.

Q: What are the typical lead time differences between custom manufacturers and standard suppliers?

A: Custom manufacturers typically require 4-16 weeks for development plus 2-12 weeks for production, while standard suppliers often deliver within days to 2-4 weeks. The timeline of a custom manufacturer can be significantly reduced if that operation is vertically integrated.

Q: Do custom manufacturers always cost more than standard suppliers?

A: Initially yes, but custom manufacturers may provide better long-term value through optimized specifications, reduced waste, and elimination of design compromises.

Engineering Excellence in Component Sourcing

The choice between custom manufacturers and standard suppliers ultimately determines how effectively you can translate innovative designs into reliable products that serve critical applications. Custom manufacturers excel when your project demands unique specifications, regulatory compliance, or integration requirements that standard components cannot address. Standard suppliers provide proven performance, rapid availability, and cost efficiency for applications where established components meet your requirements.

The most successful engineering teams understand that this choice is about finding the optimal solution for your specific requirements. Projects may even benefit from hybrid approaches that leverage both custom manufacturers and standard suppliers for different components within the same system.

At Modus Advanced, we understand the critical nature of this decision for aerospace, defense, and medical device applications. Our engineering team works with you to evaluate your specific requirements and determine whether custom manufacturing or design optimization for standard components better serves your objectives.

With AS9100 and ISO 9001 certifications, vertically integrated manufacturing processes, and over 10% of our staff dedicated to engineering support, we help aerospace, defense, and medical device companies accelerate their path to market while maintaining the quality standards that lives depend on.

Contact our engineering team today to discuss your component sourcing requirements. Because when precision matters, experience makes the difference.