Custom Metal Parts Manufacturing: Advanced Techniques for Aerospace and Defense Applications

June 27, 2025

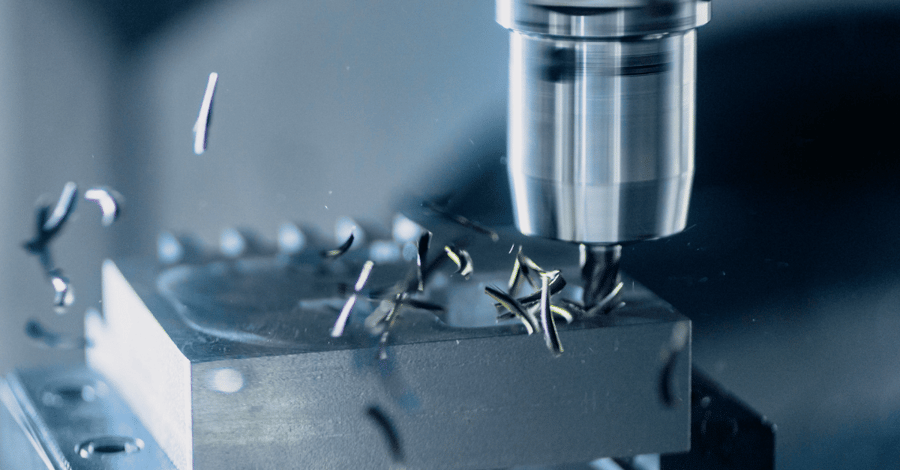

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Industry certifications like AS9100 and ITAR compliance are non-negotiable for defense, aerospace, and medical device applications

- Engineering expertise directly impacts manufacturability — partners with on-staff engineers provide critical design feedback that prevents costly redesigns

- Vertical integration reduces lead times and quality risks by eliminating handoffs between multiple vendors

- Quality systems must include real-time monitoring and documented processes to meet the stringent requirements of mission-critical applications

- Strategic partnership approach accelerates innovation by involving manufacturing partners early in the design process

Custom metal parts manufacturing forms the backbone of critical systems across defense, aerospace, and medical device industries. The precision components that enable life-saving medical equipment, protect service members in the field, and ensure safe aerospace operations require manufacturing partners who understand the stakes involved.

When lives depend on your innovation, selecting the right custom metal parts manufacturing partner becomes a mission-critical decision that extends far beyond cost considerations.

Learn everything you need to know about custom manufacturing services!

Understanding Mission-Critical Manufacturing Requirements

Mission-critical industries operate under fundamentally different pressures than commercial custom metal parts manufacturing. Defense contractors developing protective equipment face stringent compliance requirements and zero tolerance for failure. Aerospace engineers designing flight-critical systems must ensure every component performs flawlessly under extreme conditions. Medical device manufacturers creating life-support equipment know that manufacturing defects can directly impact patient outcomes.

The complexity of modern defense, aerospace, and medical systems requires components with increasingly tight tolerances, specialized materials, and complex geometries. Traditional manufacturing approaches often fall short when dealing with these demanding specifications, making partner selection a strategic decision that impacts both immediate project success and long-term innovation capabilities.

Essential Industry Certifications

Industry certifications serve as the foundation for any custom metal parts manufacturing partnership in regulated industries. These certifications demonstrate a manufacturer's commitment to the systematic quality control and documentation requirements that mission-critical applications demand.

Certification | Industry Application | Requirements | Why It Matters |

AS9100 | Aerospace & Defense | Quality management system specific to aerospace applications | Gold standard for aerospace custom metal parts manufacturing; addresses configuration management, risk management, and product safety |

Defense & Military | Security protocols and personnel clearances for defense articles | Required for defense contractors - facilities must maintain secure handling of sensitive information | |

All Industries | Baseline quality management framework | Foundation for all other certifications; demonstrates commitment to documented quality processes | |

FDA Registration | Medical Devices | Medical device quality standards and biocompatibility requirements | Essential for medical device applications requiring validated manufacturing processes |

Defense Supply Chain | Cybersecurity standards for controlled unclassified information | Emerging requirement for defense contractors to protect sensitive data |

Definition

ITAR Requirement

Defense contractors must work exclusively with ITAR-registered facilities for any components related to defense articles, making this certification a hard requirement rather than a preference.

The certification landscape continues to evolve with increasing emphasis on cybersecurity and data protection, making it essential to verify that your manufacturing partner maintains current certifications relevant to your specific application requirements.

Engineering Expertise as a Strategic Differentiator

Engineering support transforms custom metal parts manufacturing from a transactional service into a strategic partnership. Manufacturing partners with dedicated engineering teams provide critical design feedback that can prevent costly redesigns, optimize manufacturing processes, and accelerate time-to-market for mission-critical innovations.

Design for Manufacturability (DfM) reviews conducted by experienced manufacturing engineers identify potential production challenges before they become expensive problems. These reviews examine component geometry, material selection, tolerance requirements, and assembly considerations to ensure that designs can be manufactured consistently and cost-effectively.

definition

Engineering Impact

Manufacturing partners with dedicated engineering teams can reduce development timelines by identifying and resolving manufacturability issues during the design phase rather than after tooling and production have begun.

Learn MoreManufacturing engineers with industry experience understand the specific challenges that defense, aerospace, and medical applications present. They can recommend materials that meet environmental requirements, suggest design modifications that improve reliability, and identify potential failure modes that general manufacturing experience might miss.

The depth of engineering expertise becomes particularly important when dealing with complex geometries, exotic materials, or tight tolerance requirements common in custom metal parts manufacturing.

Quality Systems for Mission-Critical Applications

Quality control in custom metal parts manufacturing for mission-critical applications requires systematic approaches that go beyond traditional inspection methods. Manufacturing partners must demonstrate their ability to maintain consistent quality while providing the documentation and traceability that regulated industries require.

Statistical process control (SPC) systems provide real-time monitoring of manufacturing processes to identify variations before they result in out-of-specification parts. These systems track key process parameters and use statistical analysis to predict when processes may drift out of control.

Advanced measurement and inspection capabilities ensure that manufactured parts meet specification requirements. Coordinate measuring machines (CMMs), optical measurement systems, and specialized testing equipment provide the precision measurement capabilities that tight-tolerance applications demand.

Quality management systems must include robust documentation processes that maintain traceability from raw materials through final inspection. This documentation becomes critical for regulated industries that require complete material pedigree and process history for audit and compliance purposes.

Compliance and Security Requirements

Regulatory compliance in custom metal parts manufacturing extends beyond quality certifications to encompass security, environmental, and industry-specific requirements. Manufacturing partners must demonstrate their ability to maintain compliance across multiple regulatory frameworks while protecting sensitive information.

Cybersecurity requirements have become increasingly important as manufacturing systems become more connected. The Cybersecurity Maturity Model Certification (CMMC) establishes cybersecurity standards for defense contractors and their supply chains engaged in custom metal parts manufacturing.

key point

Security Imperative

Modern manufacturing facilities must balance operational efficiency with security requirements, implementing access controls, data protection, and facility security measures that protect both physical assets and intellectual property.

Export control regulations, including ITAR and Export Administration Regulations (EAR), govern the handling and transfer of technical data related to defense and aerospace applications. Environmental regulations affect both manufacturing processes and material selection, requiring detailed records of material composition and sourcing.

Evaluating Manufacturing Capabilities

Before you commit to any custom metal parts manufacturing partner, you need to know they can actually deliver what your application demands. This isn't about checking boxes on a capability list — it's about finding a partner who has wrestled with the same challenges you're facing and won.

Start with materials. Can they machine Inconel without work hardening? Do they understand why medical-grade stainless steel requires different handling than standard grades? Ask for examples of similar work, not just claims about what they can do.

Look at their equipment lineup. Multi-axis CNC machines are table stakes for complex geometries, but what about their secondary operations? Heat treatment, surface finishing, and assembly capabilities matter just as much as the initial machining when you're building mission-critical components.

Pay attention to capacity and flexibility. Can they handle your prototype volumes today and scale to production quantities later? More importantly, can they deliver on the timelines your program requires? The best technical capabilities mean nothing if they can't meet your schedule.

Strategic Partnership Benefits

Strategic manufacturing partnerships transform custom metal parts manufacturing from a procurement function into a competitive advantage that accelerates innovation and improves program outcomes. These partnerships provide value that extends far beyond individual transaction benefits.

Early design involvement enables manufacturing partners to provide input during the conceptual design phase when changes can have maximum impact on manufacturability, cost, and performance. This collaborative approach often identifies opportunities to simplify designs, reduce manufacturing costs, and improve reliability without compromising functionality.

Learn more about our process here!

Technology roadmap alignment ensures that manufacturing capabilities evolve to support future product requirements and industry trends. Risk mitigation benefits include diversified supply chain options, backup manufacturing capabilities, and shared responsibility for quality and delivery performance.

Making the Right Partnership Decision

Choosing a custom metal parts manufacturing partner feels overwhelming when you're weighing technical specs against budget constraints while knowing that lives may depend on your decision. The key is creating a structured evaluation process that cuts through the noise and focuses on what actually matters for your program's success.

Start by looking at their track record with projects similar to yours. Have they machined titanium components for aerospace applications? Do they understand the unique challenges of medical-grade materials? Ask for specific examples and references from customers with comparable requirements.

Next, dig into their quality systems during a site visit. You'll quickly see the difference between a partner who talks about quality and one who lives it every day. Look for real-time monitoring systems, documented processes, and a team that can explain their approach without consulting a manual.

Don't overlook the human element. How quickly do they respond to your questions? Do their engineers ask thoughtful questions about your application? The best technical capabilities mean nothing if communication breaks down when you need support most.

Financial stability matters more than you might think. You're potentially committing to a relationship that could span years or even decades. A partner who's financially solid today but struggling with cash flow could leave you scrambling for alternatives mid-program.

Accelerating Mission-Critical Innovation

The right custom metal parts manufacturing partnership does more than deliver components on time and within spec. It becomes an extension of your engineering team, helping you solve problems you didn't even know you had and pushing your innovations forward faster than you thought possible.

Think about it this way: while you're focused on perfecting the life-saving algorithm in your medical device or developing the next-generation defense system, your manufacturing partner is figuring out how to make those innovations real. They're the ones who know that switching from one titanium alloy to another could cut your weight by 15% without compromising strength, or that a small design tweak could eliminate three manufacturing steps.

When your work protects lives — whether it's a ventilator keeping patients breathing, armor protecting soldiers, or flight controls ensuring safe landings — manufacturing becomes more than a business transaction. It becomes a shared mission where precision isn't just preferred, it's essential.

At Modus Advanced, we understand that when you're developing technology that could save thousands of lives, every day in development matters. Our team of engineers — who make up more than 10% of our staff — approaches your project with the same urgency and attention to detail that you bring to your engineering challenges. With AS9100 certification, ITAR registration, and vertically integrated capabilities, we're built to accelerate mission-critical innovation.

Partner with custom metal parts manufacturing experts who understand what's at stake. Because when lives depend on your innovation, one day matters.