Depth vs. Breadth of Manufacturing Expertise: Which is Best?

October 27, 2021

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a Design

Key Points

Don’t have time for a longer read? That’s ok, we understand. We’ll give you the reader’s digest version and you can decide where you’d like to dig in more!

- Depth vs. Breadth: Common beliefs hold that you must choose between a manufacturing partner that has either a depth of expertise (e.g. an expert in a single process) or a breadth of expertise (e.g. a partner that covers many manufacturing processes).

- Pros and Cons of Depth: There is a common misconception that depth of expertise makes a manufacturer more of an “expert” in a single process.

- Pros and Cons of Breadth: Choosing a manufacturer with a breadth of expertise can help reduce lead times and production costs, improve design quality, and support strategic sourcing initiatives.

- The Best of Both: Manufacturers who “do it right” commit to hiring the right engineering staff to ensure they can provide a depth of expertise in each manufacturing process while still covering a breadth of manufacturing needs.

Depth vs. Breadth

One of the most common questions that comes up in conversations when a new company is looking to partner with us is the question of “depth vs. breadth.”

Is it better to select a manufacturing partner who is an expert in one very specific manufacturing process?

Or, is it better to select a manufacturing partner that can cover a breadth of our needs?

These are valid questions to be sure, but each of them glosses over some key nuances that are important to consider:

- Depth of expertise is often used synonymously with just “expertise,” and often those asking the questions are assuming that “depth” indicates a greater level of expertise in a specific process.

- Breadth of expertise is often assumed to mean a “one-stop-shop” and often those asking the questions assume that “breadth” indicates a lack of expertise in one of the specific manufacturing processes in question.

Making these assumptions will cause you to overlook some key decision points which may ultimately end with you selecting the wrong option for your needs. It will also cause you to miss the most important realization of all:

You don’t actually have to choose between depth and breadth of experience in a manufacturing partner. It is absolutely possible to have BOTH.

-- Article Continues Below --

Learn how Modus is transforming the traditional supplier relationship

Pros and Cons of Depth

Depth of experience indicates that a manufacturing partner specializes in one particular manufacturing process and doesn’t do work outside of that specialty.

Pros of Depth

As previously mentioned, often “depth of experience” is used synonymously with “expertise.” Commonly manufacturers with a depth of experience in a particular manufacturing process are considered “experts” in that process.

The fact that the manufacturer spends all their time working on a particular process would absolutely result in them knowing that process very well. They would likely know how to overcome common problems and could make the case for knowing that process better than other partners.

Cons of Depth

While that partner may be well versed in their particular process, there are negatives to such a narrow focus. Most parts need to undergo multiple manufacturing processes (and may even require in-house assembly in your own facilities) before they are complete.

Manufacturers with a narrow focus will be able to provide you feedback on the very narrow portion of the part production process that they have expertise in. However, they won’t have the knowledge to look at your part on the whole and determine if there are global design changes that could make it easier, more efficient, and faster to produce.

Narrowly focused manufacturers will suffer from missing the forest for the trees, so to say. They’ll be so focused on their single tree that they won’t be able to back up and look at the entire forest.

Pros and Cons of Breadth

Breadth of experience indicates that a manufacturing partner works across a variety of manufacturing processes, and can support a larger set of needs for OEMs.

Pros of Breadth

There are quite a few major pros to manufacturing partners who have a breadth of experience in a variety of manufacturing processes:

1. Strategic sourcing initiatives

In a time when many organizations are undergoing strategic sourcing initiatives, supplier consolidation becomes increasingly important. A single partner who can cover more of your needs leads to incredible internal efficiencies and risk reductions.

2. Vertical integration reduces lead times

When multiple concurrent manufacturing processes need to be executed in order to complete a part, having a single partner who can complete all of those processes can significantly reduce part lead time. Rather than sending a single part to vendor after vendor (with shipping time between each step), a manufacturer that covers a wide range of processes may be able to do it all concurrently, under one roof.

3. Better design feedback

Partners with a wider variety of expertise can provide holistic part design feedback.

We are often initially approached for a single specific process, after production has begun for other components of a part, only to find that we can provide design feedback that will make the entire process faster and less expensive.

We see the following situation all too often: a company approaches us to make or dispense a gasket that is unnecessarily complex, simply because of a design choice for the part housing. Often, if we are brought in early enough, we can provide feedback on the design of the housing (since we have metal machining expertise in addition to gasket production expertise) that makes the entire part much more seamless to produce.

Typically, after this first painful experience, customers will choose to shift to using our team for all processes required in future parts, to avoid costly redesigns or unnecessary manufacturing costs.

Cons of Breadth

The most common perceived negative about manufacturing partners that have a wide breadth of expertise is the misconception that because they do so many manufacturing processes, they aren’t an expert in any one process.

Well, my friends, we are here to dispel that myth.

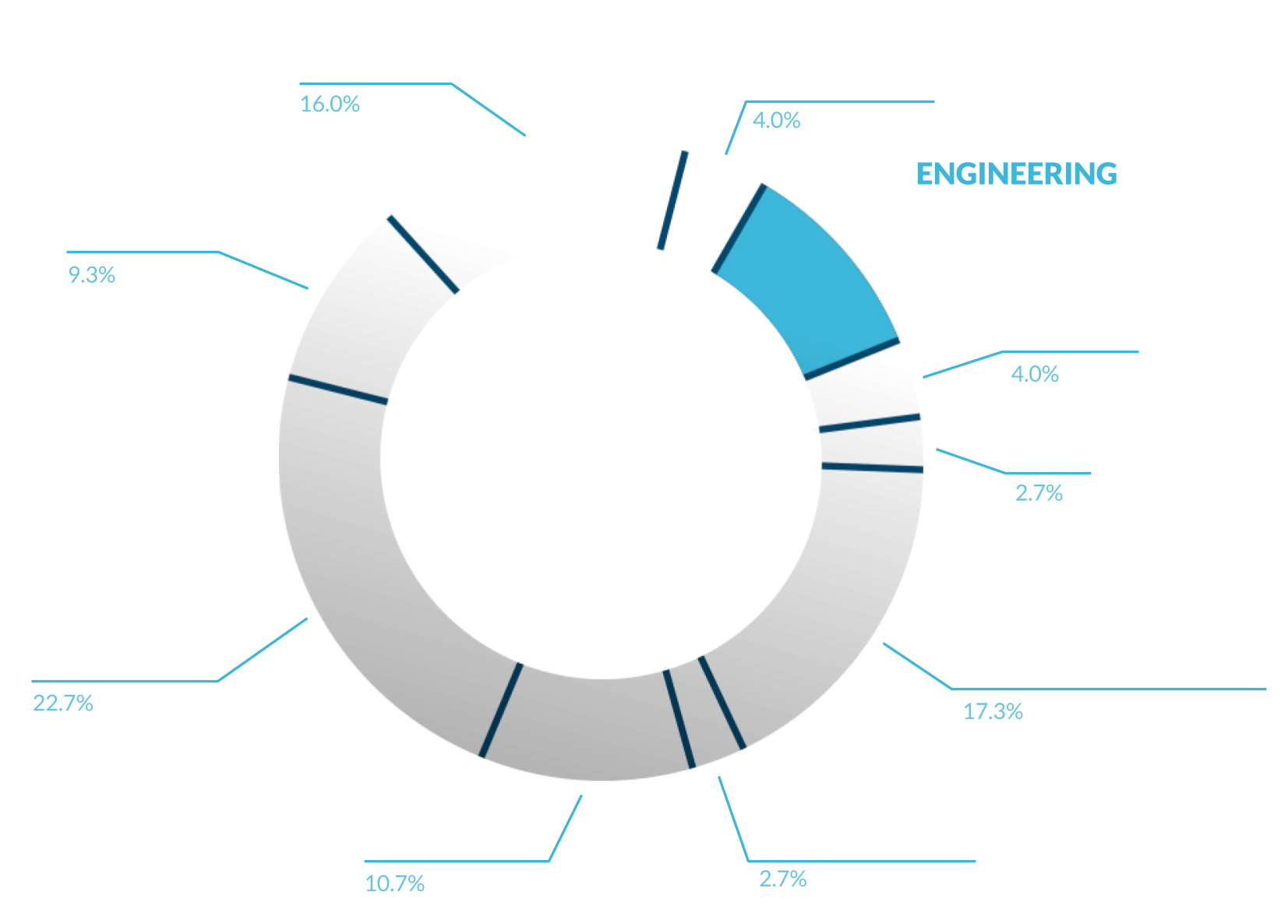

Quite simply, this comes down to how you build and structure your team. And, to ensure that we have the depth of expertise we need in each individual manufacturing process, we ensure that at least 10% of our staff are engineers.

This allows us to properly staff each department (our departments are structured individually around each of our key manufacturing processes) to ensure that we can be experts in every single process.

The Best of Both

So, when it comes down to it, why pick depth or breadth of expertise when you can have the best of both?

Learn more about how we structure our team here at Modus and the benefits of having direct access to our team of engineers.