Engineering Tolerance: Design Considerations for Manufacturing Success

September 17, 2025

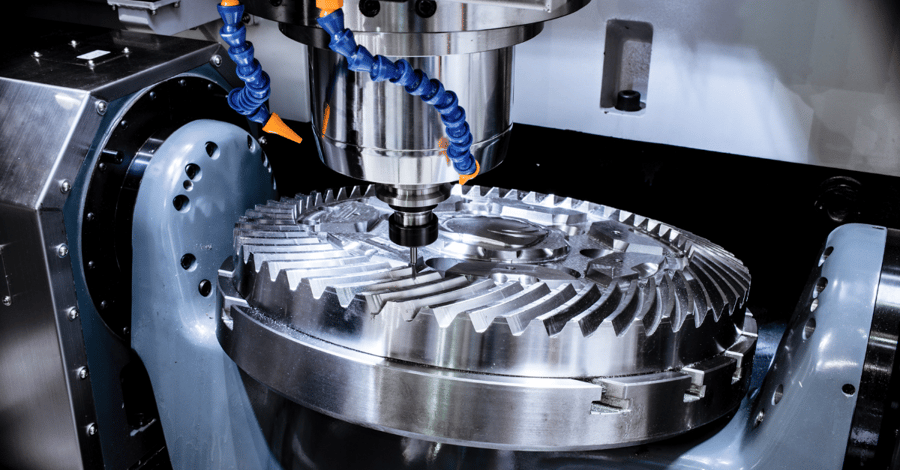

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Engineering tolerance specification directly impacts manufacturing cost, quality, and lead time — overly tight tolerances can increase production costs exponentially while loose tolerances may compromise safety in critical applications

- Typical metric manufacturing tolerance ranges vary by material properties — CNC machined metals achieve ±0.25 mm (±0.010") while elastomeric materials vary significantly based on thickness and material density

- Industry-specific tolerance requirements demand different approaches — medical device applications often require tighter tolerances for patient safety while aerospace applications balance weight considerations with precision needs

- Tolerance stack-up analysis prevents assembly issues — cumulative dimensional variations across multiple components can cause significant assembly problems if not properly managed during design

- Standard manufacturing tolerances provide cost-effective solutions — custom tighter tolerances are achievable but require specialized processes, longer lead times, and higher costs

Engineering tolerance represents the permissible deviation from a specified dimension that maintains product functionality. Every dimension specified on a technical drawing directly influences manufacturing cost, production timeline, and end-product performance.

The challenge lies in finding the optimal balance between precision and manufacturability. Specify tolerances too tightly, and manufacturing costs can skyrocket while lead times extend dramatically. Make them too loose, and product functionality, safety, or regulatory compliance may be compromised.

Understanding how tolerance decisions ripple through the entire manufacturing process enables engineers to make informed choices that optimize both performance and manufacturability. Proper engineering tolerance selection is fundamental to successful product development.

Read the Complete Guide to Machining Tolerances here!

How Material Properties Determine Tolerance Capabilities

Typical metric manufacturing tolerance varies significantly based on material characteristics and manufacturing processes. Different materials offer varying levels of achievable precision, directly impacting design decisions and cost considerations.

CNC machined metallic components typically achieve standard tolerances of ±0.25 mm (±0.010"), making them suitable for precision applications requiring consistent dimensional accuracy. This represents the industry standard for most machined metal components across aerospace, medical, and defense applications.

Elastomeric materials present more complex tolerance considerations due to their compressible nature. Film materials under 6.3 mm (0.25") thickness can achieve ±0.25 mm (±0.010") tolerance for dimensions under 25 mm (1.0"), while sponge materials in the same thickness range require ±0.63 mm (±0.025") tolerance.

Form-in-place gasket applications offer exceptional precision with standard tolerances of ±0.15 mm (±0.006"). This precision makes them ideal for EMI shielding and environmental sealing applications where consistent gasket dimensions are critical for performance.

Material Category | Standard Tolerance | Typical Applications |

CNC Machined Metals | ±0.25 mm (±0.010") | Housings, precision components |

Film Elastomers | ±0.25 mm (±0.010") | Gaskets, seals under 25 mm |

Dense Elastomers | ±0.38 mm (±0.015") | Structural gaskets |

Foam Materials | ±0.63 mm (±0.025") | Cushioning, vibration dampening |

Form-in-Place Gaskets | ±0.15 mm (±0.006") | EMI shielding, precision sealing |

Industry-Specific Engineering Tolerance Standards

Medical device manufacturing demands exceptional precision due to patient safety requirements. Ventilator components, for example, require consistent sealing performance where dimensional variations could affect life-support functionality. The stakes involved often justify tighter tolerances despite increased manufacturing complexity.

Aerospace and defense applications balance multiple competing requirements simultaneously. Weight optimization drives material selection, while mission-critical performance demands reliability. Components operating in extreme temperature ranges from -55°C to +125°C (-67°F to +257°F) must maintain dimensional stability across these conditions.

Space applications present unique challenges where serviceability is impossible once deployed. Every component must perform flawlessly throughout its operational life, often requiring tolerance specifications that account for long-term material behavior and thermal cycling effects.

Regulatory compliance directly influences engineering tolerance decisions. AS9100 certification requirements in aerospace applications, FDA regulations in medical devices, and ITAR compliance in defense applications all impact how tolerances are specified and verified.

Understanding Tolerance Stack-Up in Assembly Design

Individual component tolerances combine in assemblies to create cumulative dimensional variations that can cause significant assembly problems. A gasket assembly involving five components, each with ±0.25 mm tolerance, could theoretically result in ±1.25 mm total variation if all tolerances stack in the same direction.

Statistical analysis provides more realistic stack-up calculations for engineering tolerance management. Using root-sum-square methods, the same five-component assembly would more likely exhibit ±0.56 mm variation. This approach enables more accurate assembly predictions while avoiding unnecessarily tight individual component tolerances.

Critical seal interfaces require special attention during tolerance stack-up analysis. Environmental sealing applications where gasket compression must fall within specific ranges need careful tolerance allocation to ensure proper sealing performance across production variations.

Form-in-place gasket start and stop zones present unique tolerance considerations. These areas, extending 3 mm in each direction around termination points, may exhibit height variations of -30% to +45% from nominal dimensions due to the dispensing process characteristics.

Cost Impact of Engineering Tolerance Decisions

Standard manufacturing tolerances provide the most cost-effective solutions for most applications. These tolerances leverage existing equipment capabilities and standard quality control processes, minimizing both production costs and lead times.

Tighter-than-standard tolerances require specialized manufacturing approaches. Additional machining passes, enhanced measurement systems, and increased inspection frequency all contribute to higher costs. Secondary operations often become necessary when standard processes cannot achieve required tolerances.

Hand-finishing, selective assembly, or specialized fixturing may be required for precision applications. This significantly impacts production scalability and cost structure. Quality systems must also scale with tolerance requirements, demanding more sophisticated measurement equipment, climate-controlled environments, and enhanced operator training.

The relationship between engineering tolerance and manufacturing cost is exponential rather than linear. Each incremental tightening of tolerance requirements can result in disproportionate cost increases across the entire production process.

Balancing Performance Requirements and Manufacturing Efficiency

Functional requirements should always drive engineering tolerance decisions. Critical dimensions affecting product performance, safety, or regulatory compliance justify tighter tolerances despite increased costs. Non-critical dimensions can often accept standard tolerances without compromising product functionality.

Design for manufacturability principles encourage engineers to specify the loosest acceptable tolerance for each dimension. This approach optimizes manufacturing efficiency while maintaining product performance requirements and cost effectiveness.

Communication between design and manufacturing teams proves essential for successful tolerance implementation. Early engagement with manufacturing partners enables tolerance optimization based on specific process capabilities and limitations.

The goal is achieving required functionality with the most manufacturable design possible. This balance ensures product success while controlling development costs and production timelines.

Frequently Asked Questions About Engineering Tolerance

What is the difference between engineering tolerance and manufacturing tolerance?

Engineering tolerance refers to the allowable deviation specified during design, while manufacturing tolerance represents what can actually be achieved during production. Understanding both is crucial for successful product development.

How do you determine appropriate tolerance requirements?

Tolerance requirements should be based on functional necessity, regulatory compliance, assembly requirements, and cost considerations. Start with the loosest acceptable tolerance and tighten only when function demands it.

What are typical metric manufacturing tolerance ranges for different processes?

CNC machining typically achieves ±0.25 mm (±0.010"), die cutting varies from ±0.25 mm to ±0.63 mm depending on material, and form-in-place processes can achieve ±0.15 mm (±0.006").

Achieving Manufacturing Excellence Through Engineering Partnership

Successful tolerance management requires deep understanding of both design requirements and manufacturing capabilities. Engineers benefit from partnering with manufacturers who possess comprehensive process expertise and advanced quality systems.

Our team of engineers — representing more than 10% of our staff — provides design for manufacturability feedback that optimizes tolerance specifications for your specific applications. This engineering-first approach ensures your designs achieve required performance while maintaining manufacturing efficiency.

Our AS9100 and ISO 9001 certifications demonstrate our commitment to quality systems capable of meeting demanding tolerance requirements. When applications require tighter-than-standard tolerances, our vertically integrated processes and advanced measurement systems provide the flexibility needed for success.

Whether your application involves life-saving medical devices, mission-critical defense systems, or innovative aerospace technologies, proper tolerance management ensures your products perform reliably when lives depend on them. Partner with us to optimize your designs for manufacturing success while maintaining the precision your applications demand.