Thermal Interface Materials: Making the Right Choice for Your Application

July 26, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Thermal interface materials encompass both dispensed solutions and discrete pads, each offering distinct advantages for different engineering applications

- Dispensed thermal interface materials provide superior thermal performance due to better surface wetting and reduced contact resistance compared to pre-cut pads

- Thermal pads offer exceptional portability and ease of use without requiring specialized dispensing equipment or operator training

- Volume requirements significantly influence cost-effectiveness — dispensed solutions become more economical at higher production volumes (hundreds of thousands of units)

- Material waste considerations favor dispensed solutions, which can achieve near-zero waste compared to thermal pads that typically yield 80-95% sheet utilization

Heat management challenges in modern electronics demand precise thermal interface materials selection. Engineers designing everything from life-saving medical devices to mission-critical defense systems face increasing thermal loads in shrinking form factors.

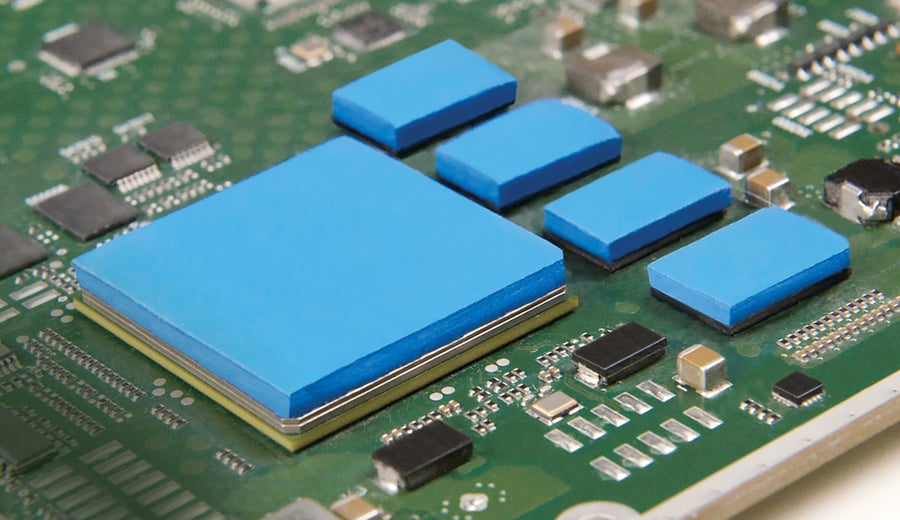

Thermal interface materials (TIMs) are specialized compounds designed to enhance heat transfer between two surfaces by filling microscopic air gaps and surface irregularities. The choice between dispensed thermal interface materials and discrete thermal pads affects thermal performance, manufacturing efficiency, cost structures, and production scalability.

Read the Complete Engineer's Guide to Thermal Management

Thermal Interface Materials Categories and Definitions

Thermal interface materials fall into two primary categories that engineers must understand for effective implementation:

Definition

What are Dispensed Thermal Interface Materials (TIMs)?

Dispensed thermal interface materials include thermally conductive pastes, gels, and fillers applied directly during assembly using automated dispensing equipment. These materials cure or set in place, conforming precisely to component geometries.

Learn MoreDefinition

What are Thermal Pads?

Thermal pads are pre-manufactured sheets cut to specific dimensions before assembly. These discrete components offer immediate usability without requiring specialized application equipment.

Learn MoreBoth categories reduce thermal contact resistance, but their implementation approaches create distinct engineering considerations for design teams.

Performance Characteristics: Engineering Physics in Practice

Thermal performance differences between dispensed thermal interface materials and pads stem from fundamental physics principles that directly impact system reliability.

Contact Resistance and Surface Conformity

Dispensed thermal interface materials excel in thermal performance because they wet mating surfaces completely during application. This liquid-state contact eliminates microscopic air gaps that create thermal resistance, resulting in 15-30% better thermal performance compared to equivalent thermal pads.

Thermal pads maintain slight air gaps due to surface irregularities and manufacturing tolerances, which increase thermal contact resistance, particularly on rough or uneven surfaces.

Operating Temperature and Thermal Conductivity

Both thermal interface materials solution types accommodate wide temperature ranges for standard formulations, with specialized options extending ranges for extreme environment applications in aerospace and defense systems.

Parameter | Dispensed TIMs | Thermal Pads |

Temperature Range | -55°C to 125°C (-67°F to 257°F) | -55°C to 125°C (-67°F to 257°F) |

Thermal Conductivity | 1-10+ W/mK | 1-8 W/mK |

Performance Advantage | Superior surface conformity | Consistent thickness control |

Contact Resistance | Lower (better performance) | Higher due to air gaps |

Dispensed Thermal Interface Materials: Manufacturing Efficiency

Dispensed solutions offer compelling advantages for high-volume production environments where thermal performance and material efficiency drive design decisions.

Material Efficiency and Cost Optimization

Dispensed thermal interface materials achieve near-zero waste through precise volume control. Engineers can program exact material quantities for each application, eliminating waste inherent in pad cutting operations.

Key Benefits:

- 10-20% cost savings compared to die-cut thermal pads in high-volume applications

- Accommodation of multiple-part geometries without tooling changes

- Reduced inventory complexity for product families with varied requirements

Operational Considerations

Programming dispensing equipment requires initial setup time (typically hours for complex patterns), but program storage enables rapid changeovers between product variants.

Thermal Pads: Simplicity in Critical Applications

Pre-cut thermal pads provide immediate usability advantages that make them attractive for many engineering applications requiring thermal interface materials.

Manufacturing and Tooling

Die cutting delivers excellent dimensional control, particularly critical for thin materials where thickness tolerances directly affect thermal performance.

Aspect | Specification | Impact |

Tooling Cost | $250-$500 per configuration | Negligible across production runs |

Die Lifespan | Tens of thousands of parts | Excellent long-term value |

Dimensional Control | ±0.05mm thickness tolerance | Predictable thermal performance |

Sheet Utilization | 80-95% depending on geometry | Material waste consideration |

Portability and Assembly Flexibility

Thermal pads excel in distributed manufacturing environments:

- Ship easily without special handling requirements

- Integrate into existing assembly processes without equipment additions

- Support complex supply chain requirements common in aerospace and medical device manufacturing

- Enable pre-assembly on heat sinks for secondary integration

Material Selection Diversity

The thermal pad market offers extensive material variety from global suppliers, providing engineers with hundreds of thermal interface materials formulation options. This diversity supports specialized requirements including biocompatibility for medical applications or outgassing specifications for space systems.

Volume-Based Decision Framework

Production volume requirements create clear decision boundaries between thermal interface materials approaches:

Production Volume | Recommended Solution | Primary Considerations |

< 10,000 units | Thermal Pads | Setup costs, tooling investment |

10,000 - 100,000 units | Case dependent | Break-even analysis required |

> 100,000 units | Dispensed TIM | Material efficiency, automation benefits |

> 500,000 units | Dispensed TIM (strongly recommended) | Maximum efficiency, quality control |

Annual volume projections should account for product lifecycle scaling, as initial pad-based solutions may require conversion to dispensed thermal interface materials as volumes increase.

Application-Specific Engineering Considerations

Thermal interface materials selection depends heavily on application context beyond pure thermal performance requirements.

Design Revision Flexibility

- Dispensed TIMs: Accommodate design changes through software updates (hours implementation)

- Thermal Pads: Require new tooling for dimensional changes (1-2 weeks lead time)

Quality System Integration

Manufacturing quality systems must accommodate the chosen thermal interface materials approach:

- Dispensed solutions: Require process validation, equipment qualification, operator certification

- Thermal pads: Integrate easily into existing quality systems but require incoming inspection protocols

Environmental and Compliance Requirements

Both thermal interface materials approaches must satisfy environmental regulations and industry-specific compliance requirements. Medical device applications require biocompatibility validation, while aerospace applications demand outgassing and flammability certifications.

Frequently Asked Questions About Thermal Interface Materials

Q: What is the difference between thermal interface materials and thermal pads?

A: Thermal interface materials is the broader category that includes both dispensed solutions and discrete thermal pads.

Q: Which thermal interface materials provide better thermal performance?

A: Dispensed thermal interface materials typically provide 15-30% better performance due to superior surface wetting.

Q: At what production volume do dispensed thermal interface materials become cost-effective?

A: Typically at production volumes exceeding 100,000 units annually, due to reduced material waste and automation benefits.

Making the Engineering Decision

The optimal thermal interface materials solution balances thermal performance requirements with manufacturing constraints and cost objectives. Primary decision factors include production volume projections, thermal performance requirements, manufacturing process constraints, and total cost of ownership calculations.

Successful thermal interface materials selection requires early collaboration between thermal design teams, manufacturing engineers, and supply chain professionals to ensure all constraints receive proper consideration.

Accelerating Thermal Management Innovation

Modern thermal challenges demand sophisticated solutions that balance performance with manufacturability. Whether your application requires the precision of dispensed thermal interface materials or the simplicity of thermal pads, the right choice accelerates your innovation timeline.

At Modus Advanced, our engineering team understands that thermal interface materials decisions affect entire system architectures. With over 10% of our staff being engineers, we provide the technical expertise to optimize your thermal interface materials selection while supporting your broader design objectives.

Our vertically integrated capabilities encompass both dispensed thermal interface materials and precision thermal pad manufacturing, ensuring your thermal management solution aligns with your production requirements. When thermal performance affects patient outcomes or mission success, choosing the right partner makes all the difference.