Tight Tolerance Manufacturing: Design for Manufacturing Guidelines

September 19, 2025

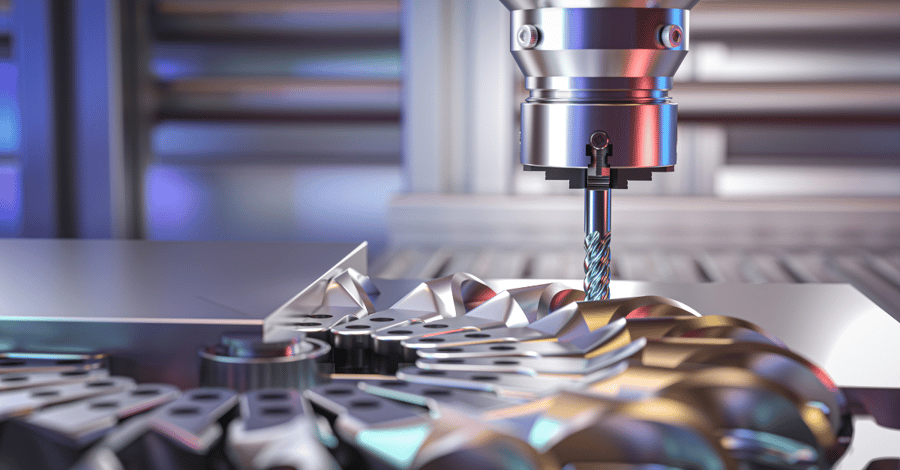

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Functional requirements drive tolerance specifications: Tighten tolerances only when design function truly demands it, as each reduction in tolerance significantly impacts cost and lead time

- Material selection affects achievability: Different materials respond uniquely to machining processes, with some naturally supporting tighter tolerances than others

- Geometric complexity multiplies tolerance challenges: Complex geometries with multiple tight tolerance requirements create exponential manufacturing difficulties

- Early manufacturing collaboration prevents costly redesigns: Involving machining expertise during design phase identifies potential issues before they become expensive problems

- Quality systems become critical at tight tolerances: Precision measurement and process control capabilities determine success in achieving consistent results

When a surgeon depends on your medical device to save a patient's life, or when a pilot trusts your aerospace component at 30,000 feet, precision is imperative. Tight tolerance manufacturing forms the backbone of these critical applications.

Engineering teams face mounting pressure to develop components with ever-increasing precision requirements. The challenge lies not just in specifying tight tolerances, but in designing parts that can be manufactured reliably, cost-effectively, and within reasonable lead times. Understanding the principles of Design for Manufacturing (DFM) becomes essential when working with precision machined components from a tight tolerance machine shop.

Read the Complete Guide to Machining Tolerances here!

Understanding Tight Tolerances in Critical Applications

Tight tolerance manufacturing typically refers to dimensional requirements that exceed standard manufacturing capabilities. While standard CNC machining achieves tolerances of ±0.010" (±0.25 mm), tight tolerance applications often demand precision ranging from ±0.005" (±0.13 mm) down to ±0.001" (±0.025 mm) or even tighter in specialized cases.

The definition of "tight" varies significantly across industries and applications. Medical device components may require sub-micron precision for proper function, while aerospace applications might focus on tight tolerances for weight optimization and performance reliability. Defense applications often combine both requirements, demanding exceptional precision under extreme environmental conditions.

Understanding why tight tolerances matter in your application helps determine where precision is truly necessary versus where standard tolerances suffice. A medical device housing that interfaces with other precision components may require tight tolerances at mating surfaces while allowing standard tolerances on non-critical features.

The Engineering Balance: Function vs. Manufacturability

Every engineer faces the fundamental challenge of balancing functional requirements against manufacturing reality. Tight tolerance manufacturing serves specific engineering purposes: ensuring proper fit and function, optimizing performance characteristics, maintaining safety margins, and enabling interchangeability of components.

However, each tightening of tolerance specifications creates cascading effects throughout the manufacturing process. Tighter tolerances require more sophisticated equipment, increased setup time, additional quality control measures, and often multiple machining passes to achieve the desired precision.

The key lies in applying tight tolerances selectively and strategically. Critical functional surfaces deserve tight tolerance specifications, while non-critical features should maintain standard tolerances to minimize manufacturing complexity and cost.

Tolerance Range | Typical Applications | Manufacturing Considerations | Relative Cost Impact |

±0.010" (±0.25 mm) | Standard machining | Conventional CNC processes | Baseline |

±0.005" (±0.13 mm) | Precision assemblies | Enhanced process control | 2-3x increase |

±0.002" (±0.05 mm) | Critical interfaces | Specialized equipment required | 4-6x increase |

±0.001" (±0.025 mm) | Ultra-precision applications | Advanced machining centers | 8-12x increase |

Material Considerations for Precision Machining

Material selection significantly impacts the achievability of tight tolerances in machined parts. Different materials exhibit varying responses to machining forces, thermal effects, and tool interactions, all of which affect dimensional stability and surface finish in tight tolerance machine shop operations.

Material characteristics that affect tight tolerance manufacturing:

- Aluminum alloys: Excellent thermal conductivity and dimensional stability for precision applications

- Steel alloys: Superior dimensional stability but require robust machining approaches

- Stainless steel: Work-hardening characteristics present unique tight tolerance challenges

- Titanium alloys: High strength-to-weight ratio but difficult to machine consistently

- Inconel and superalloys: Extreme temperature resistance with specialized machining requirements

Aluminum alloys generally machine well and maintain dimensional stability, making them excellent choices for tight tolerance applications. The material's thermal conductivity helps dissipate heat during machining, reducing thermal expansion issues that can affect precision.

Steel alloys offer excellent dimensional stability but require more robust machining approaches. Tool wear becomes a critical factor, as worn cutting tools can introduce dimensional variations that compromise tight tolerance requirements.

Stainless steel presents unique challenges for tight tolerance manufacturing due to its work-hardening characteristics. The material can become increasingly difficult to machine as cutting tools engage, potentially leading to dimensional inconsistencies if not properly managed.

Geometric Complexity and Tolerance Interactions

Complex geometries amplify the challenges of achieving tight tolerances in machined parts. Features such as deep cavities, thin walls, complex contours, and intersecting surfaces each introduce variables that can affect dimensional accuracy in precision manufacturing.

Common geometric challenges in tight tolerance manufacturing:

- Thin-walled sections: Machining forces cause deflection affecting tolerance achievement

- Deep cavities: Limited tool access and heat buildup compromise precision

- Complex contours: Multiple setup requirements increase tolerance stack-up risks

- Intersecting features: Competing tolerance requirements create manufacturing conflicts

Thin-walled sections present particular challenges, as machining forces can cause deflection that prevents achievement of tight tolerances. Wall thickness-to-height ratios become critical design considerations, with support strategies often necessary to maintain rigidity during machining operations.

Internal features like deep holes, cavities, or complex internal geometries limit tooling access and make it difficult to maintain tight tolerances. Tool deflection, vibration, and heat buildup in confined spaces can all contribute to dimensional variations that compromise precision requirements.

Cost and Lead Time Implications

Tight tolerance manufacturing creates significant impacts on both manufacturing cost and production lead times. These effects compound as tolerance requirements become more stringent, often following exponential rather than linear progressions.

Setup time increases substantially for tight tolerance work, as achieving precision requires careful machine calibration, tooling preparation, and fixturing setup. What might take 30 minutes for standard tolerance work could require several hours for tight tolerance applications.

Tool wear monitoring becomes critical, as even minor tool degradation can push dimensions outside tight tolerance bands. More frequent tool changes and closer monitoring drive up production costs and extend machining times.

Quality control requirements intensify dramatically for tight tolerance parts. Standard inspection methods may prove inadequate, requiring investment in precision measurement equipment and additional inspection time that extends overall lead times.

Collaboration Strategies with Manufacturing Partners

Successful tight tolerance manufacturing projects require close collaboration between design teams and manufacturing partners from the earliest design phases. Early engagement allows manufacturing expertise to inform design decisions before drawings are finalized and expensive modifications become necessary.

Design reviews should include detailed discussions of tolerance requirements and their justifications. A qualified tight tolerance machine shop can often suggest alternative approaches that achieve the same functional requirements with more manufacturable tolerance specifications.

Material selection benefits tremendously from manufacturing input, as machinists understand how different alloys behave under various cutting conditions. This knowledge helps optimize both material choice and machining strategies for tight tolerance success.

Key collaboration elements for tight tolerance success:

- Early design reviews: Include manufacturing input before finalizing specifications

- Tolerance justification discussions: Ensure every tight tolerance serves a specific functional purpose

- Material optimization: Leverage manufacturing knowledge for material selection

- Fixturing coordination: Design parts with robust workholding in mind

- Quality planning: Establish measurement strategies during design phase

featured article

DFM Guidelines for Aerospace: Engineering for Mission Success

Learn Morefeatured article

What Happens During a Design for Manufacturability (DFM) Review?

Learn Morefeatured article

What Happens During a SigShield™ DFM: a Design for Manufacturability Review and Consultation Service?

Learn MoreQuality Assurance in Tight Tolerance Production

Quality assurance becomes paramount when working with tight tolerance manufacturing, as the margin for error decreases dramatically with tighter specifications. Traditional measurement methods may lack the precision necessary to verify conformance to tight tolerance requirements.

Coordinate measuring machines (CMMs) often become essential for tight tolerance verification, providing the accuracy and repeatability necessary to measure dimensions within very small tolerance bands. However, CMM measurement introduces its own considerations, including temperature control, part stabilization, and measurement uncertainty calculations.

Essential quality control methods for tight tolerance manufacturing:

- Coordinate Measuring Machines (CMMs): Sub-micron accuracy for critical dimensions

- Statistical Process Control (SPC): Real-time monitoring to prevent drift

- Environmental controls: Temperature and humidity management for consistency

- Advanced metrology: Optical and laser measurement systems for complex geometries

Process control takes on increased importance in tight tolerance machining. Statistical process control (SPC) methods help identify trends before they result in out-of-specification parts, enabling proactive adjustments that maintain precision throughout production runs.

Environmental factors like temperature, humidity, and vibration can significantly impact both machining operations and measurement results. Controlled manufacturing environments become increasingly important as tolerance requirements tighten.

Optimizing Your Design for Manufacturing Success

Designing successful tight tolerance manufacturing requires understanding the interplay between functional requirements, manufacturing capabilities, and economic constraints. The goal is achieving necessary precision while maintaining reasonable cost and delivery expectations.

Tolerance specification should follow a strategic approach, applying tight tolerances only where functionally necessary. Designers should clearly understand which dimensions truly require tight control and which can accommodate standard manufacturing tolerances without compromising performance.

Feature design significantly impacts manufacturability of tight tolerance parts. Simple, accessible geometries generally support tighter tolerances more readily than complex features that limit tooling access or create difficult setup conditions.

Design optimization strategies for tight tolerance success:

- Selective tolerance application: Tighten only functionally critical dimensions

- Accessible geometry: Design features that support robust machining approaches

- Clear documentation: Use GD&T to communicate requirements and intent effectively

- Manufacturing input: Involve machining expertise during development

- Realistic expectations: Balance precision requirements with cost and schedule constraints

When your engineering team faces tight tolerance requirements for critical applications, partner with a manufacturing team that understands both the technical challenges and the stakes involved. At Modus Advanced, our engineering-first approach — with over 10% of our staff being degreed engineers — ensures your precision components receive the expertise they deserve.

Our AS9100 and ISO 9001 certifications, combined with our commitment to 99% on-time delivery and 99% quality ratings, provide the reliability your critical applications demand. Because when lives depend on precision, choosing the right manufacturing partner isn't just about capability — it's about ensuring mission success when failure isn't an option.

Frequently Asked Questions About Tight Tolerance Manufacturing

What tolerance range qualifies as "tight tolerance manufacturing"?

Tight tolerance manufacturing typically involves tolerances tighter than ±0.005" (±0.13 mm), with ultra-precision applications reaching ±0.001" (±0.025 mm) or tighter.

How do I choose the right tight tolerance machine shop?

Look for shops with advanced CNC equipment, environmental controls, precision measurement capabilities, and relevant industry certifications like AS9100 for aerospace applications.

What materials work best for tight tolerance applications?

Aluminum alloys offer excellent machinability and stability, while steel alloys provide superior dimensional stability. Material choice depends on application requirements and environmental conditions.

How much do tight tolerances increase manufacturing costs?

Costs typically increase 2-3x for ±0.005" (±0.13 mm) tolerances, 4-6x for ±0.002" (±0.05 mm), and 8-12x for ±0.001" (±0.025 mm) compared to standard tolerances.