Tolerance Tool & Engineering: Measurement and Verification Strategies

September 23, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

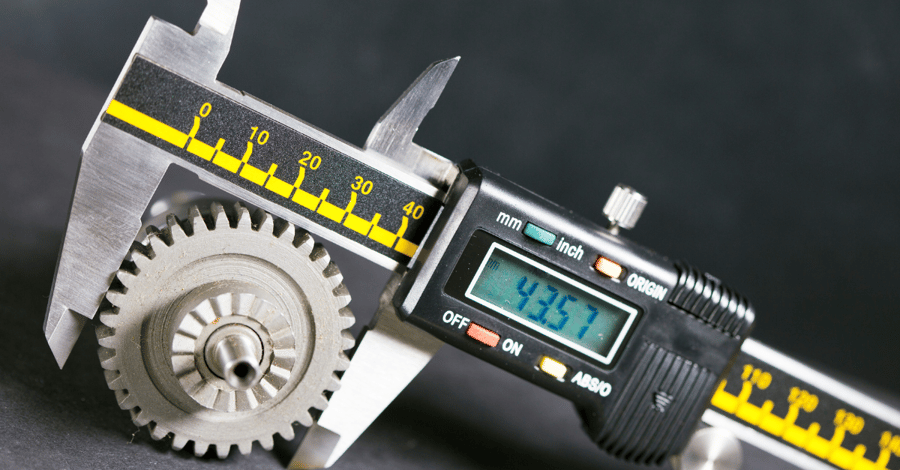

- Precision verification: Modern metrology equipment enables measurement accuracy to within ±0.002 mm (±0.0001"), critical for aerospace and medical device applications

- Stage-gate validation: Implementing verification checkpoints throughout production prevents costly downstream failures and ensures dimensional accuracy

- Industry-specific requirements: Medical device components demand different tolerance verification approaches compared to aerospace applications due to varying regulatory and performance standards

- Data-driven quality control: Advanced measurement systems generate real-time data that enables predictive quality management and continuous process improvement

- Tolerance stack-up analysis: Proper verification strategies account for cumulative dimensional variations across multi-component assemblies

What Is Tolerance Tool & Engineering in Manufacturing?

Tolerance tool & engineering represents the intersection where design intent meets manufacturing reality. When medical devices must perform flawlessly in operating rooms or aerospace components must withstand extreme conditions, verification strategies become the guardian of mission-critical reliability.

Machine tolerance verification ensures components meet exact specifications through systematic measurement and quality control processes. The challenge extends beyond simply meeting dimensional specifications — engineers must establish verification protocols that validate not only individual component tolerances but also how those tolerances interact within complex assemblies.

Read the Complete Guide to Machining Tolerances here!

The Foundation of Precision Manufacturing Tolerance Control

Machine tolerance verification begins with understanding the relationship between design requirements and manufacturing capabilities. Standard manufacturing tolerances provide the baseline for most applications, but critical components often demand enhanced precision through specialized processes and verification methods.

CNC machining typically achieves standard tolerances of ±0.010" (±0.25 mm) for metallic components. Form-in-place gasket manufacturing maintains standard bead tolerances of ±0.006" (±0.15 mm). These baseline capabilities serve as the foundation for developing appropriate verification strategies.

However, tolerance tool & engineering goes beyond standard capabilities. Engineers must evaluate when tighter tolerances truly enhance function versus when they simply increase manufacturing complexity and cost. This evaluation requires comprehensive understanding of how measurement uncertainty, environmental factors, and production variability affect final component performance.

Advanced Metrology Equipment and Inspection Technologies

Modern verification strategies rely on sophisticated quality and measurement technologies that provide the accuracy and repeatability necessary for critical applications. Coordinate measuring machines (CMMs) form the backbone of dimensional verification, offering three-dimensional measurement capabilities with sub-micron accuracy.

Vision measurement systems complement traditional contact-based metrology by enabling rapid inspection of complex geometries without potential damage to delicate components. These systems prove particularly valuable for medical device components where surface integrity cannot be compromised.

Laser scanning and optical measurement technologies provide non-contact verification for components that cannot withstand contact probe forces. These technologies excel in measuring soft materials, thin films, and components with complex surface textures that traditional methods struggle to assess accurately.

The selection of appropriate metrology equipment depends on component geometry, material properties, and required measurement uncertainty. Engineers must balance measurement accuracy requirements against inspection throughput needs to maintain production efficiency while ensuring quality standards.

Stage-Gate Verification Strategies Across Production

Effective tolerance verification implements checkpoints throughout the manufacturing process rather than relying solely on final inspection. First article inspection validates that manufacturing processes can achieve design specifications before full production begins.

In-process monitoring catches dimensional drift before it produces non-conforming parts. Statistical process control charts track key dimensions over time, enabling predictive maintenance and process adjustments that prevent quality issues rather than simply detecting them.

Real-time measurement systems integrated into manufacturing equipment provide immediate feedback on dimensional accuracy. These systems enable automatic process corrections that maintain tolerances within specified limits without operator intervention.

Final inspection validates that completed components meet all dimensional and functional requirements. This stage combines comprehensive dimensional verification with functional testing to ensure components will perform as intended in their final application.

Verification Stage | Primary Purpose | Typical Equipment | Key Benefits |

First Article | Process validation | CMM, optical scanner | Prevents production of non-conforming parts |

In-Process | Real-time monitoring | Inline gauges, vision systems | Immediate process correction capability |

Final Inspection | Complete verification | CMM, functional testers | Comprehensive quality assurance |

Industry-Specific Machine Tolerance Requirements

Medical device manufacturing demands verification strategies that account for biocompatibility requirements alongside dimensional accuracy. Components that contact human tissue require not only precise dimensions but also surface finish verification and material composition validation.

Sterilization processes can affect dimensional stability, requiring verification protocols that account for post-sterilization dimensional changes. Medical device components often undergo multiple sterilization cycles throughout their lifecycle, making long-term dimensional stability a critical verification parameter.

Aerospace and defense applications face different challenges, with components experiencing extreme temperature variations from -65°C to 200°C (-85°F to 392°F), vibration, and mechanical stresses. Verification strategies must validate performance under these conditions, not just at standard laboratory temperatures and conditions.

Space applications add radiation exposure and vacuum conditions to the verification requirements. Components must maintain dimensional accuracy and functionality after exposure to space environments that can cause material degradation and dimensional changes over time.

The regulatory environment also influences verification strategies. Medical devices regulated under FDA guidelines require different documentation and traceability compared to aerospace components following AS9100 standards. These regulatory requirements shape both the verification protocols and the data management systems that support them.

Data-Driven Quality Control Methods for Machine Tolerance

Modern tolerance verification generates vast amounts of measurement data that enables sophisticated quality control methods. Statistical analysis of measurement data reveals patterns that predict potential quality issues before they affect production.

Machine learning algorithms analyze measurement trends to identify process variations that correlate with dimensional deviations. These systems learn from historical data to predict when processes require adjustment, enabling proactive quality management rather than reactive problem-solving.

Digital twin technology creates virtual models of manufacturing processes that incorporate real measurement data. These models simulate how process variations affect final component dimensions, enabling optimization of both manufacturing parameters and verification strategies.

Data visualization tools transform complex measurement datasets into actionable insights for engineers and operators. Real-time dashboards highlight critical dimensions approaching tolerance limits, enabling immediate corrective action.

Traceability systems link measurement data to specific manufacturing parameters, creating a complete record of how each component was produced. This data proves invaluable for root cause analysis when quality issues arise and for continuous improvement initiatives.

Tolerance Stack-Up Analysis and Validation

Complex assemblies require verification strategies that account for how individual component tolerances combine to affect overall assembly function. Tolerance stack-up analysis predicts assembly-level dimensional variation based on individual component tolerances and assembly methods.

Monte Carlo simulation techniques model how random variations in component dimensions affect assembly performance. These simulations help engineers optimize tolerance allocations to minimize assembly-level variation while maintaining manufacturing efficiency.

Assembly-level verification validates that tolerance stack-up predictions match actual results. Measurement of critical assembly dimensions confirms that individual component verification strategies effectively control overall assembly performance.

Root Sum Square (RSS) and worst-case analysis methods provide different approaches to tolerance stack-up calculation. Engineers select the appropriate method based on assembly criticality, production volume, and acceptable risk levels.

Stack-Up Method | Application | Risk Level | Manufacturing Cost |

Worst-Case | Critical assemblies | Lowest | Highest |

Root Sum Square | Standard assemblies | Moderate | Moderate |

Monte Carlo | Complex assemblies | Variable | Variable |

Geometric dimensioning and tolerancing (GD&T) principles guide tolerance stack-up analysis by clearly defining how component variations affect assembly function. Proper GD&T application enables more efficient tolerance allocation and verification strategies.

Frequently Asked Questions About Tolerance Tool & Engineering

What is the difference between tolerance and machine tolerance?

Tolerance refers to the allowable variation in a dimension, while machine tolerance specifically refers to the precision capabilities of manufacturing equipment. Machine tolerance represents the achievable accuracy limits of specific manufacturing processes.

How do you verify machine tolerance accuracy?

Machine tolerance verification uses calibrated measurement equipment like CMMs, optical scanners, and gauge blocks to measure actual part dimensions against specified tolerances. Regular calibration of measurement equipment ensures accuracy.

What metrology equipment is required for precision tolerance verification?

Essential equipment includes coordinate measuring machines (CMMs), optical measurement systems, surface profilometers, and calibrated gauge blocks. Equipment selection depends on required accuracy, part geometry, and material properties.

How does temperature affect tolerance verification?

Temperature changes cause material expansion and contraction, affecting dimensional measurements. Standard measurement temperature is 20°C (68°F), and temperature compensation may be required for accurate verification.

Partnering with Precision Manufacturing Excellence

Effective tolerance tool & engineering requires manufacturing partners who understand the critical relationship between design intent, manufacturing capability, and verification strategy. Success depends on early collaboration between design engineers and manufacturing experts who can optimize tolerance requirements for both function and manufacturability.

AS9100 and ISO 9001 certifications provide the quality system foundation necessary for rigorous tolerance verification. These standards ensure that verification processes maintain consistency and traceability throughout production.

Engineering expertise becomes crucial when standard tolerances prove insufficient for critical applications. Creative engineering solutions can achieve tighter tolerances when function truly requires enhanced precision, though engineers must understand the cost and lead time implications of these decisions.

Vertically integrated manufacturing capabilities enable comprehensive tolerance verification under a single quality system. This integration reduces the risk of tolerance accumulation across multiple suppliers while maintaining complete control over verification protocols.

The investment in advanced metrology equipment and quality engineering expertise demonstrates commitment to precision manufacturing. When components must perform flawlessly in life-critical applications, choosing a manufacturing partner with proven tolerance verification capabilities becomes essential for mission success.