CNC Machining Services for RF Shields

August 10, 2022

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a Design Key Points

Key Points

- CNC machining is just one of the several manufacturing processes that must be completed in order to build a complete RF shield.

- Finding a vertically integrated partner to machine your RF shield’s metal housing will ensure that your finished product is done right the first time.

- A vertically integrated partner will also be able to provide key design feedback on how different manufacturing processes will interfere with each other.

You have many choices when it comes to selecting a CNC machining partner for RF shield production. When looking for the best partner for machining the metal housing for your shield, you’ll be considering who can deliver parts the fastest, meet your quality requirements, and give the kind of design feedback that allows you to get your RF shield done right the first time.

Using the traditional approach of sending your shield to multiple different vendors based on manufacturing process specialty will result in lost time, higher costs, and issues with failures between manufacturing processes.

--Article Continues Below--

Read Everything You Need To Know About CNC Machining

Why You Want a Vertically Integrated Partner

Here at Modus Advanced, we have turned RF shield production into a turnkey process called SigShield. Because we’ve been asked to support the manufacturing of so many RF shields, we’ve ironed out a clear process to deliver a completed shield from start to finish.

We offer all concurrent manufacturing processes that need to be completed in order to deliver an RF shield in a single process:

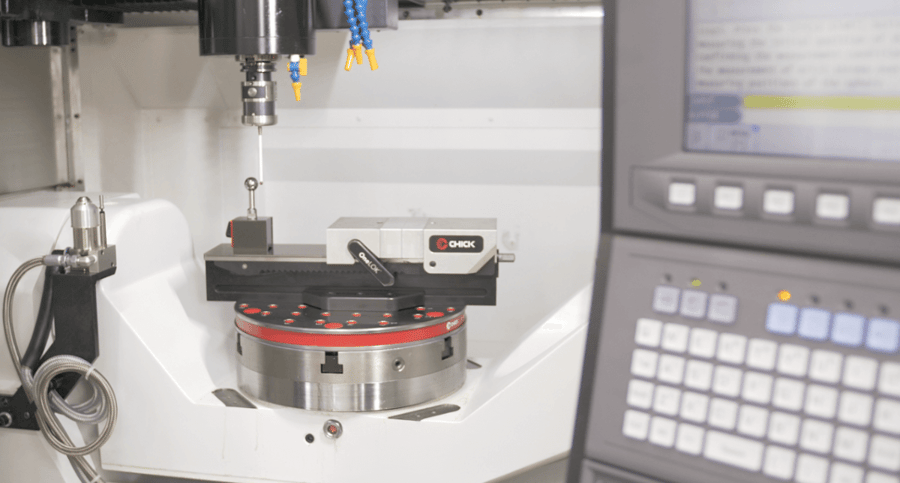

- CNC Machining of Metal Housing: We start by machining your metal housing according to your design requirements.

- Application of Plating & Coatings: Once your housing has been machined, we'll apply required platings or coatings as specified in your designs.

- Installation of Inserts: Most RF shields require the installation of helicoils and various other inserts.

- Form-in-Place Gasket Dispensing: Once your housing is completed, we'll apply form-in-place gaskets as specified in your design.

- Addition of Thermal Materials and/or Microwave Absorbers: In parallel with machining and FIP dispensing, we can manufacture thermal materials and/or microwave absorbers to apply to your part before shipping.

We realized this process was necessary after being handed so many RF shielding projects where OEMs had run into issues managing processes between multiple vendors.

The Pains of the Traditional Approach

Let us demonstrate with an example. This case study breaks down the story of Signal Hound, a test equipment manufacturer struggling with the production of an RF shield. They were using the traditional approach, with separate vendors for CNC machining, coating, and FIP gasket dispensing.

Production of the part had been delayed for over 6 months with attempts to troubleshoot issues between plating and the application of FIP that was making it impossible for the FIP to adhere to the housing according to their design specifications. When separate vendors are responsible for each process, nobody has ultimate responsibility for the completion of the part, and what ends up happening is lots of finger-pointing.

--Article Continues Below--

Visit the Modus CNC Machining Resource Center

Vertical Integration Solves Problems

When Signal Hound approached Modus, who handles all of the concurrent processes in house, the problem was solved quickly. Because our engineering teams have experience in all manufacturing processes, they understand how each affects each other and we were able to give immediate design feedback to help solve the issues with FIP adherence.

Ultimately a vertically integrated CNC machining partner provides 4 clear benefits:

- Shorter lead times: Because you aren’t shipping between different vendors, we can usually cut lead times in half when compared to the traditional process.

- Lower total cost: Again, because you aren’t shipping between different vendors, you have significant savings on freight costs.

- Better design feedback: Because our team is familiar with all processes, they can provide important design feedback on features that will cause issues between processes.

- Less administrative overhead: Life is just simpler when you’re working with a single vendor rather than four to complete a part.

Machining Metal Housings for RF Shields

Our team has helped with CNC machining for thousands of RF shields. Over the course of our experience, we’ve seen some common design features on CNC machined housing that can lead to issues later down the line in the assembly process.

Some key design considerations that will help make it faster to machine your shield and make it easier for the application of form-in-place gaskets include:

- Go for Large Inside Corner Radii

- Don’t Make Pockets Too Deep

- Pay Attention to Pre-Drill Tapping Depth

- Avoid Side Work in Multiple Orientations

- Give Tapped Holes Some Wall Clearance

- Prefer Specified Edge Breaks Over Modeled Chamfers

- For Heatsinks, Go Wide

- Design with Gasket Width in Mind

- Compression Stops Over Grooves to Control FIP Gasket Height

- Instead of Small O-Ring Grooves, Use an FIP Gasket

- Keep Hardware to a Minimum

- For Quality Inspection Requirements, Be Specific

- When Setting Tolerances, Go Big When Possible

Dive into all of these recommendations in more detail in this article.

SigShieldTM: The Ultimate Process for Machined RF Shields

Ultimately, the SigShield™ process saves you time, money and stress when producing RF shields. And who wouldn’t want all of that from a single vendor?

Submit a design today to see if SigShield™ is a fit for your project.