Key Benefits to Working with a Nolato EMC Production Partner for EMI Shielding Solutions

January 30, 2018

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a Design‘Leaving it to the experts’ can be a mutually beneficial proposition for both the expert and the other party. In industry, this concept is a convenient way of allowing both parties, each familiar with a certain field, to hone their skill set and become trusted, esteemed experts in that field.

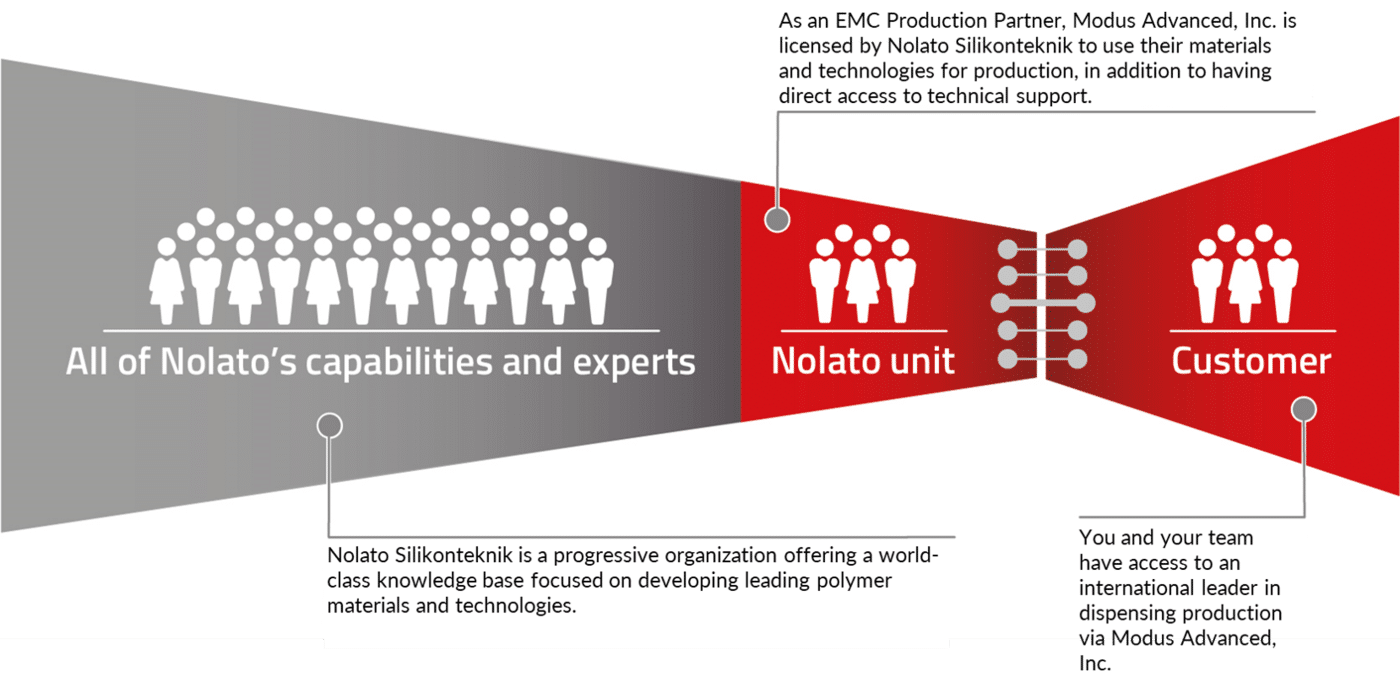

Modus Advanced, Inc. embraces this concept through its partnership with Nolato Silikonteknik, a company that produces high-quality electromagnetic shielding solutions. Nolato has many electromagnetic compatibility (EMC) Production Partners around the world (one of them being Modus Advanced, Inc.) who are trusted to use Nolato’s shielding material and technologies for large-scale production. A significant benefit of a Mechanical Engineer working with one of Nolato’s EMC Production Partners to manufacture electromagnetic shielding products is that these partners provide hands-on, local support at their business centers, making Nolato’s customers their customers, too. This partnership optimizes the cost, time, and efficiency involved with the product-to-market process.

What is EMI Shielding and why is it important?

Electronic equipment—computers, cell phones, and test instrumentation, among other types—permeate everyday life, and the use of electronic equipment is only increasing. When electronic equipment is used, electromagnetic radiation is emitted, which is likewise increasing. This in turn leads to an increased demand of products and equipment that should not disturb (or be disturbed by) other electronic systems. Electromagnetic interference (EMI) can disrupt electronic devices, equipment, and systems used in many EMI shielding applications. Examples of this type of equipment include medical, military, and aerospace electronics; mass transit systems; industrial touch screens; and navigation and vehicular control systems, in addition to many others. The causes of EMI are numerous and include both man-made and natural sources. The results can range from temporary disturbances and data losses to system failure and even loss of life.

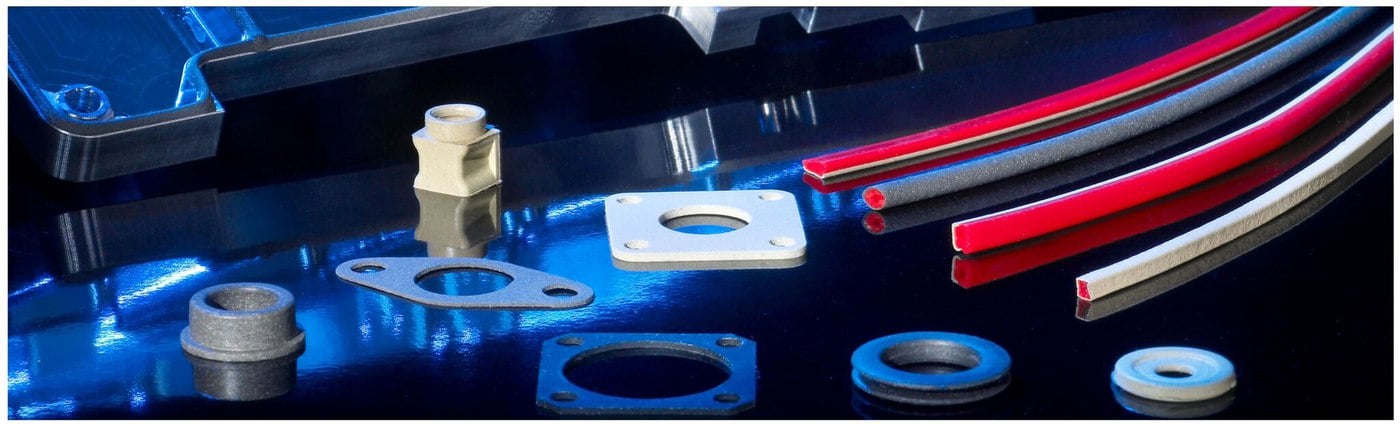

EMI Shielding Solutions (Source: Nolato)

EMI Shielding Solutions (Source: Nolato)

EMI is one of many unwanted effects that fall under the EMC branch of electrical engineering, which is concerned with the unintentional generation, propagation, and reception of electromagnetic energy. EMC ensures the correct operation of different equipment which use or respond to electromagnetic phenomena and avoids interference effects. A simple explanation: EMC is the control of EMI so that unwanted effects are prevented. The goal of EMC is the correct operation of different equipment in a common electromagnetic environment.

Nolato Silikonteknik

Nolato Silikonteknik was founded in 1938 as Nordiska Latexfabriken i Torekov, with the acronym Nolato, which has been the company's name since 1982. Today, Nolato Silikonteknik produces particle-loaded electrically conductive silicone materials in a variety of forms to address electromagnetic interference shielding. Nolato’s silicone compounding expertise also let to the development of their Compatherm Thermal Interface Materials (TIM). Their products are used by high-tech industries—such as telecommunications, automotive, medical, and security—globally. With its headquarters in Sweden and an expertly trained worldwide partner network, Nolato and its partners leverage the incredibly efficient distributed model to serve customers at a local level.

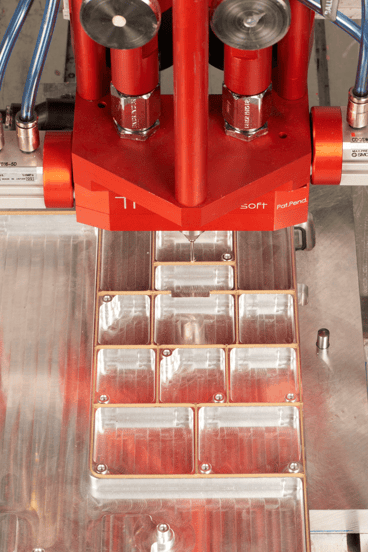

Among Nolato’s state-of-the-art offerings is its Trishield® technology, a unique dispensing process widely used by leading companies in high-tech industries requiring electromagnetic interference (EMI) shielding. Trishield® offers a solution that combines excellent shielding effectiveness with superior mechanical performance and is used to form the dispensed EMC gaskets into a triangular shape, thus reducing material usage and the required compression force to create an effective shield.

Compashield® is Nolato’s brand for molded and extruded EMI gaskets in the form of cans, frames, tubes, sheets, and components. The technique involves molding or extruding electrically conductive silicone rubber into a precise size and shape. The cross-section can be rectangular, solid, or hollow, in various shapes and dimensions. Thanks to Nolato, designers no longer need to choose between an environmental seal or an EMI shielding gasket—Nolato merged both gasket types into a sole product. Compashield® Extrusion features a thin, electrical conductivity shield co-extruded on a high-performance silicone rubber base.

Visit our complete EMI shielding resource center.

What is an EMC Production Partner?

Nolato’s licensed EMC Production Partners have entered into a contract with Nolato and have been provided with the necessary technology, training, and equipment for manufacturing products using Nolato's material. Both sides must agree to Nolato’s Trishield® Licensee agreement. In most cases, Nolato’s end customers, such as Nokia or Ericsson, have requested that Nolato setup certain companies as licensed EMC partners. “In this case, Nolato has a direct reference from a high-end customer which carries considerable weight,” says Rodney Boyd, the North American Nolato Sales Manager. “We must then advise, train and support on-site as needed to make sure the processes are dialed in and our material is being dispensed as intended.” Nolato stays in touch with the end customer and provides support for any issues that arise.

There are approximately 30 EMC Production Partners worldwide who produce Nolato products and assume responsibility for the overhead, equipment, production, and direct client interactions. “Our customers essentially become customers of our EMC Production Partners,” says Boyd.

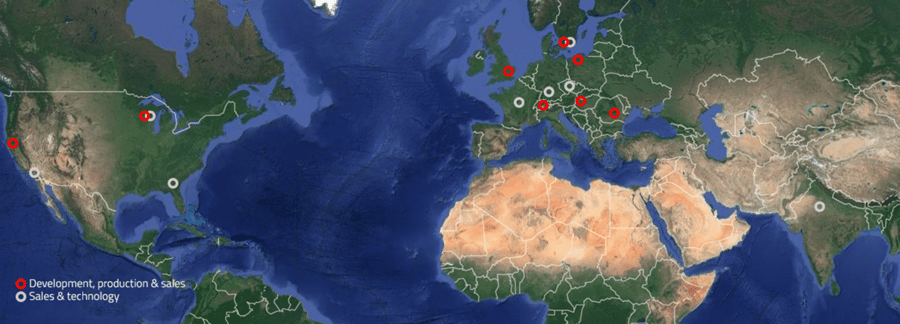

Nolato carefully selected strategically-located partners in North America, Europe, India and Asia to serve customers on a local level. Nolato also has its own dispensing centers in Sweden and Malaysia, with an additional center in Hungary to be added soon.

Key Partnership Benefits

While there are many benefits to a partnership like this one, some key benefits include the flexibility in product location and the cross-fertilization of ideas and knowledge between the technical staff at Nolato and the EMC Production Partners. Other benefits are:

Key partnership benefits for EMC Production Partners

- EMC Production Partners receive training using advanced systems that Nolato provides. Among these technologies are:

- A professional dispensing system

- A turnkey process for dispensing Nolato’s materials

- A proven quality-control process

- Nolato’s established research and development lab is available to all EMC Production Partners for support.

- EMC Production Partners leverage international equipment.

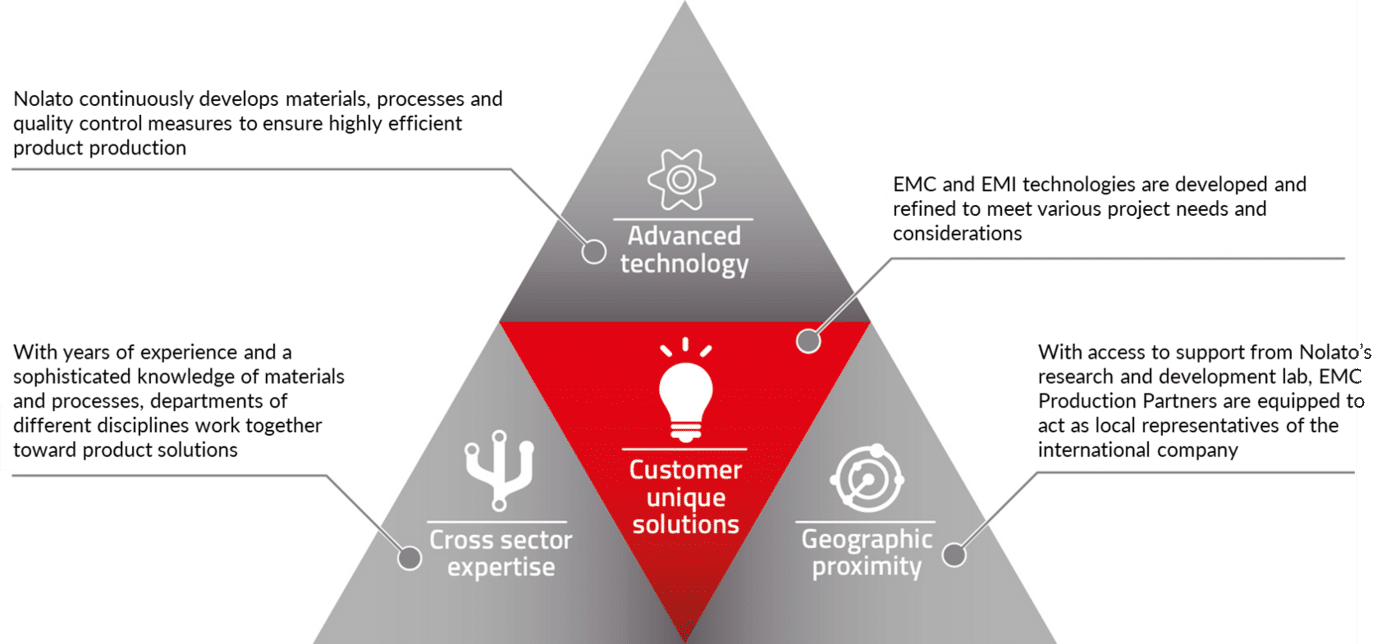

One Nolato Principle (Source: Nolato)

One Nolato Principle (Source: Nolato)Key partnership benefits for customers

- The same production techniques and quality-control processes are used by every Nolato Production Partner, ensuring the same products of the same quality are available at any Production Partner location worldwide.

- Thanks to Nolato’s 30 EMC Production Partners, customers can obtain Nolato products virtually anywhere in the world. The extreme flexibility saves on freight costs and reduces stops in a global supply chain.

- Engineering customers have access to a local representative (the EMC Production Partner) of an international leader in dispensing production.

- If additional support is needed, the EMC Production Partner has direct access to Nolato’s technical staff in Sweden and China—if any problems or questions arise, they can be addressed.

- The customer has access to Nolato’s high-quality materials though the partner model.

Nolato Solution Triangle (Source: Nolato)

Why is working with a Nolato EMC Production Partner the best choice for your EMI Shielding Solutions?

It’s important to trust the quality of your EMI Shielding product, the manufacturer who produced it, and the level of customer support behind it. By working with an EMC Production Partner, you’ll have confidence in these qualities—the production partners undergo thorough training using state-of-the-art technology to precisely fabricate the EMI Shielding product you need, all while having the knowledge of Nolato’s research and development team at their fingertips.