Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Laser communication terminals require black optical coatings with solar absorptance above 0.97 and thermal emittance above 0.90 to achieve effective stray light suppression and thermal stability in LEO and GEO environments.

- MLS-85-SB delivers 0.98 solar absorptance and 0.91 thermal emittance with a flexible silicone binder system that accommodates thermal cycling from -180°C to 600°C (-292°F to 1112°F).

- MLS-85-SB-C provides identical optical performance to MLS-85-SB while adding controlled electrical conductivity (~10⁵ Ω/sq) for static dissipation in sensitive optical systems.

- Stray light control in laser communication systems demands nonspecular black coatings on baffles, telescope housings, and internal optical surfaces to maintain signal integrity across inter-satellite distances exceeding 40,000 km.

- Space-qualified formulations with documented flight heritage — including the Optical Properties Monitor mission with 9 months of orbital exposure — ensure reliable performance for both commercial space and defense applications.

What Makes Black Optical Coatings Critical for Laser Communication Terminals?

Satellite laser communication represents a fundamental shift in how data moves through space. These optical inter-satellite link systems require specialized black coatings to achieve bandwidth increases of 10 to 100 times over conventional radio frequency systems, with demonstrated data rates reaching 1.8 Gbps and beyond.

The physics behind this performance advantage creates unique engineering challenges. A laser beam traveling between a geostationary satellite at 36,000 km altitude and a low Earth orbit satellite expands to approximately 500 meters at 40,000 km distance. This narrow beam width demands pointing accuracy measured in microradians and creates extreme sensitivity to any stray light entering the optical path.

Black optical coatings serve as the critical interface between system performance and environmental interference. Without proper stray light suppression, internal reflections and scattered light degrade the signal-to-noise ratio that makes high-bandwidth laser communication possible.

Essential Background Reading:

- Black Optical Coatings for Satellite Laser Communication Terminals: Complete engineering guide covering coating fundamentals for laser communication systems

- Optical Black Coatings Overview: Foundation concepts for stray light suppression in aerospace applications

- Organic vs Inorganic Coatings Comparison: Key differences in binder systems, cure times, and environmental resistance

- Satellite Communication Component Manufacturing: Overview of Modus capabilities for satcom systems

Why Laser Communication Terminals Require Specialized Black Optical Coatings

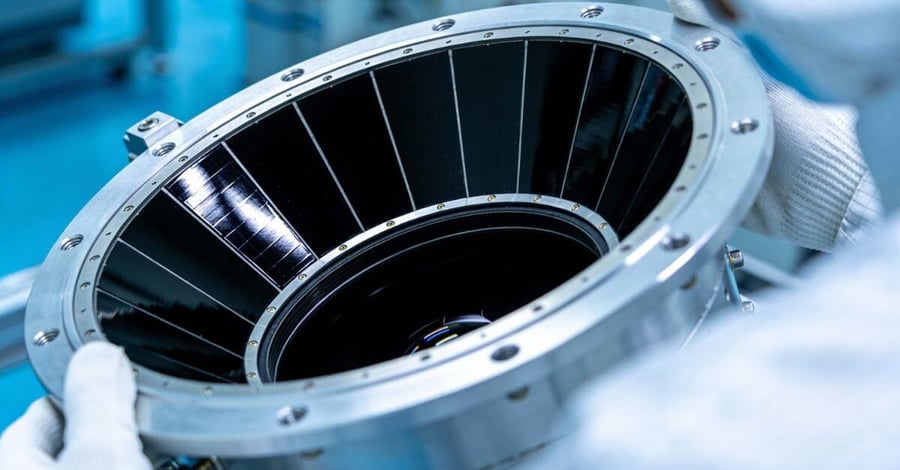

The optical components within a laser communication terminal face demanding performance requirements. Baffles, telescope housings, and internal optical surfaces must absorb unwanted light across a broad spectrum while surviving the thermal extremes of space operations.

Sources of Stray Light in Optical Communication Systems

Stray light in laser communication systems originates from multiple sources. External illumination from the sun, Earth, and moon can overwhelm sensitive detectors if not properly attenuated. Internal stray light from retroreflectance and scattering within the optical path creates interference that limits transmission distance and data rates.

Effective suppression requires coatings that absorb incoming radiation rather than reflecting or scattering it. High solar absorptance (αs) captures incident energy, while high thermal emittance (εt) allows that absorbed energy to radiate away without creating thermal gradients that distort optical alignment. Engineers working on laser communication component manufacturing for next-generation space connectivity understand these requirements intimately.

Understanding Optical Performance Requirements for Space Applications

Engineers selecting black optical coatings for laser communication terminals must balance several interdependent performance characteristics. The coating's optical properties directly impact system sensitivity, while its thermal behavior affects both component longevity and optical alignment stability.

Solar Absorptance

Solar absorptance measures the fraction of incident solar radiation that a surface absorbs rather than reflects. For stray light suppression in laser communication terminals, values above 0.97 provide the attenuation necessary to prevent detector saturation and maintain signal discrimination.

Thermal Emittance

Thermal emittance describes how effectively a surface radiates thermal energy compared to an ideal blackbody. High emittance values — typically above 0.90 — enable passive thermal management without active cooling systems that add weight, complexity, and potential failure modes to satellite optical systems.

Nonspecular Finish Quality

The nonspecular quality of a coating determines whether absorbed light scatters diffusely or reflects in predictable directions. Black optical coatings for laser communication terminals must eliminate specular reflections that could direct stray light directly into sensitive detector arrays.

MLS-85-SB: Flexible Black Thermal Control Coating for Optical Applications

MLS-85-SB represents a specialized solution for laser communication terminal applications requiring both optical performance and mechanical flexibility. The coating's silicone binder and carbon black pigment system delivers the high absorptance values necessary for stray light control while maintaining the flexibility needed to survive launch vibration and thermal cycling. For detailed technical specifications, our MLS-85-SB black thermal control paint material guide provides comprehensive engineering data.

The coating achieves a solar absorptance of 0.98 ± 0.01 and thermal emittance of 0.91 ± 0.02 at the nominal dry thickness of 76 μm (0.003") over at least 85% of the coated surface area. These values provide the optical performance that laser communication terminals demand for reliable operation.

MLS-85-SB operates across a temperature range from -180°C to 600°C (-292°F to 1112°F), covering the thermal extremes encountered in both LEO and GEO environments. The organic formulation accommodates thermal expansion differences between the coating and substrate without cracking or delamination.

Property | MLS-85-SB Specification |

Solar Absorptance (αs) | 0.98 ± 0.01 |

Thermal Emittance (εt) | 0.91 ± 0.02 |

Operating Temperature | -180°C to 600°C (-292°F to 1112°F) |

Nominal Dry Thickness | 76 μm (0.003") |

Cure Time | 48-72 hours at room temperature |

Finish | Nonspecular optical black |

Binder System | Silicone |

Related Content:

- Coatings for Satellite Imaging Systems: Similar design principles for light management in optical payloads

- Cutting-Edge Optical Coatings Guide: Broader perspective on coating technologies for aerospace performance

- Anti-Reflective Coatings for Space: Complementary coating systems for comprehensive optical system designs

- Thermal and Optical Control Coatings Process: Modus coating capabilities and application methods

- Satellite Downlink Communications Components: Related manufacturing for complete satellite communication systems

MLS-85-SB-C: Electrically Conductive Black Optical Coating

Many laser communication systems incorporate electronic components in close proximity to optical surfaces. These configurations create electrostatic discharge concerns that standard optical black coatings cannot address.

MLS-85-SB-C extends the MLS-85-SB formulation with controlled electrical conductivity. The coating maintains the same solar absorptance (0.98 ± 0.01) and thermal emittance (0.91 ± 0.02) while providing surface resistivity of approximately 10⁵ Ω/sq for static dissipation.

This controlled conductivity prevents charge accumulation that could damage sensitive electronics or create discharge events that interfere with communication signals. The coating provides charge dissipation capability without creating short-circuit paths that would compromise system isolation.

Property | MLS-85-SB | MLS-85-SB-C |

Solar Absorptance | 0.98 ± 0.01 | 0.98 ± 0.01 |

Thermal Emittance | 0.91 ± 0.02 | 0.91 ± 0.02 |

Surface Resistivity | Non-conductive | ~10⁵ Ω/sq |

Temperature Range | -180°C to 600°C (-292°F to 1112°F) | -180°C to 600°C (-292°F to 1112°F) |

ESD Protection | No | Yes |

Application Methods | Spray, brush | Spray, brush |

Space Environment Performance and Flight Heritage

Both MLS-85-SB and MLS-85-SB-C demonstrate resistance to atomic oxygen exposure found in Low Earth Orbit environments. The Optical Properties Monitor mission validated MLS-85-SB performance with 9 months of orbital exposure, providing flight heritage that supports mission-critical applications.

Atomic Oxygen Resistance

Atomic oxygen flux — the bombardment by highly reactive oxygen atoms present at LEO altitudes between 180-650 km — causes rapid degradation of many organic materials. The silicone binder system in these coatings resists this erosion mechanism while maintaining optical and thermal properties throughout extended mission durations.

Engineers should note that atomic oxygen testing for these coatings remains limited for extended exposure periods. Applications with long-duration LEO exposure requirements should include material evaluation as part of the qualification process.

GEO Environment Suitability

For Geosynchronous Earth Orbit applications, atomic oxygen concerns diminish substantially. Both MLS-85-SB and MLS-85-SB-C coatings provide excellent service as baffle absorptance coatings in GEO environments where thermal cycling and radiation exposure present the primary material challenges. Our guide on precision optical and thermal control coatings for satellite imaging systems explores these environmental considerations in greater depth.

Next Steps:

- OISL Component Manufacturing Guide: Comprehensive manufacturing considerations for optical inter-satellite link parts

- MILSATCOM Engineering Solutions: Military satellite communications requiring defense-grade manufacturing

- Thermal Control Coatings Complete Guide: Deep dive into thermal emittance and solar absorptance management

- CNC Machining Capabilities: Precision aluminum housing production for OISL telescope assemblies

Application Methods and Manufacturing Process Advantages

MLS-85-SB and MLS-85-SB-C offer significant manufacturing advantages over many competing black optical coatings. The silicone-based formulations cure at room temperature within 48-72 hours without requiring controlled temperature and humidity environments.

Spray Application

Spray application achieves the specified optical properties when proper atomization pressure and material flow rates are maintained. The coatings can be applied over complex geometries using high-volume, low-pressure systems that deposit uniform films across curved surfaces and internal features common in laser communication terminal designs.

Brush Application Considerations

Brush application provides an alternative for repairs, small areas, or situations where spray equipment is impractical. Brush-applied coatings may not achieve the same solar absorptance and thermal emittance values as spray-applied films. Mission-critical laser communication terminal applications should specify spray application for consistent optical performance.

Surface Preparation Requirements

Surface preparation requirements remain consistent with aerospace coating standards. Substrates must be clean and free from contamination, oils, and loose particles before coating application begins. Proper surface preparation directly impacts coating adhesion and long-term performance in the space environment.

Design Considerations for Laser Communication Terminal Components

Engineers incorporating black optical coatings into laser communication terminal designs should consider several factors that influence coating selection and application strategy. Our comprehensive resource on advanced coatings for laser communication systems in space provides additional design guidance.

Baffle Design Optimization

Baffle design directly impacts stray light performance. The coating's nonspecular finish works in conjunction with vane geometry to absorb and trap incident light before it reaches detector surfaces. Miniaturized baffles with angled vanes can improve Point Source Transmittance (PST) by 2-3 times at small incident angles when combined with appropriate black optical coatings.

Internal Optical Surface Requirements

Internal optical surfaces present distinct requirements from external components. These surfaces benefit from the low outgassing characteristics essential for maintaining optical clarity in vacuum systems. MLS-85-SB's minimal outgassing properties make it suitable for enclosed optical assemblies where contamination could degrade lens and mirror performance in laser communication systems.

Thermal Management Integration

Thermal management integration requires coordinating coating selection with overall system thermal design. The high emittance values of both MLS-85-SB and MLS-85-SB-C support passive radiative cooling strategies that reduce system complexity and power consumption — critical considerations for satellite optical inter-satellite link systems. Engineers evaluating alternative thermal control solutions may also benefit from our RM-550-IB black thermal control paint material guide for applications requiring different performance characteristics.

Quality Assurance for Mission-Critical Applications

Coating performance verification requires appropriate measurement capabilities and quality processes. Solar absorptance and thermal emittance measurements validate that applied coatings meet specification requirements before integration into flight hardware.

Thickness Verification

Thickness verification ensures adequate coating deposition across complex geometries. The nominal 76 μm (0.003") thickness specification must be achieved over at least 85% of the coated surface area to guarantee optical performance for laser communication terminal components.

Adhesion Testing

Adhesion testing per ASTM D3359A confirms proper bonding between the coating and substrate. MLS-85-SB specifies adhesion not less than 3A, ensuring the coating remains attached through launch loads and thermal cycling throughout the mission lifetime.

Frequently Asked Questions About Black Optical Coatings for Laser Communication Terminals

What solar absorptance is required for laser communication terminal coatings?

Laser communication terminals require black optical coatings with solar absorptance values above 0.97 for effective stray light suppression. MLS-85-SB and MLS-85-SB-C both achieve 0.98 ± 0.01 solar absorptance, providing the attenuation necessary to prevent detector saturation in space-based optical communication systems.

How do black optical coatings improve laser communication performance?

Black optical coatings absorb unwanted light that would otherwise scatter within the optical path and degrade signal-to-noise ratio. The nonspecular finish eliminates specular reflections that could direct stray light into sensitive detector arrays, enabling reliable data transmission across distances exceeding 40,000 km.

Can MLS-85-SB withstand LEO atomic oxygen exposure?

MLS-85-SB demonstrates resistance to atomic oxygen exposure through its silicone binder system. The coating's flight heritage includes 9 months of orbital validation on the Optical Properties Monitor mission. Applications with extended LEO exposure should include material evaluation as part of qualification testing.

When should I choose MLS-85-SB-C over MLS-85-SB?

MLS-85-SB-C should be selected when optical components require both stray light suppression and electrostatic discharge protection. The controlled conductivity (~10⁵ Ω/sq) prevents charge accumulation near sensitive electronics without compromising optical performance.

What cure time do these coatings require?

Both MLS-85-SB and MLS-85-SB-C cure at room temperature within 48-72 hours. This eliminates the need for controlled temperature and humidity environments during manufacturing, simplifying production processes for laser communication terminal components.

What other black thermal control coatings are available for aerospace applications?

Beyond MLS-85-SB and its conductive variant, engineers should evaluate coating options based on specific mission requirements. Our ML-210-IB black thermal control paint material guide covers alternative formulations that may better suit certain application requirements.

See It In Action:

- Building a 10-Year Strategic Relationship: How Modus supports long-term satellite telecommunications partnerships

- Engineering Custom Solutions for Space-Critical Components: Custom manufacturing approaches for demanding aerospace tolerances

- Combating Supply Chain Challenges with Materials Knowledge: How deep materials expertise solved space program delays

Partnering for Precision Coating Application

Black optical coatings for laser communication terminals demand manufacturing expertise that goes beyond standard industrial coating processes. The combination of tight optical specifications, space-qualified materials, and complex component geometries requires partners who understand both the coating science and the application requirements.

Modus Advanced brings specialized coating application capabilities alongside aerospace quality management systems certified to AS9100 and ISO 9001 standards. Our ITAR registration and CMMC compliance protect sensitive technical data throughout the manufacturing process — essential considerations for defense and commercial space programs.

Our satellite communication component manufacturing capabilities extend beyond coatings to include the full range of processes needed for complete optical terminal assemblies. This vertical integration reduces supply chain complexity while maintaining the quality standards that space applications demand.

Our engineering team engages early in the design process to provide feedback on coating selection, application strategy, and design for manufacturability. This collaborative approach helps identify potential issues before they impact production schedules or mission timelines. For programs involving RF communication systems alongside optical terminals, our guide on aerospace components manufacturers for RF communication systems covers complementary manufacturing considerations.

For laser communication programs where reliable optical performance supports mission success, partnering with a manufacturer who understands the stakes makes a measurable difference. When your terminal's ability to maintain communication links across 40,000 km depends on proper stray light suppression, the coating on every baffle and housing matters.

Contact our engineering team to discuss your laser communication terminal coating requirements. Because when lives and missions depend on reliable space communication, one day matters.