Educational Resources

Complete Tight Tolerance Machining Resource Center

Browse all of our educational resources about Tight Tolerance Machining.

Guide Articles Case Study

CNC MACHINING

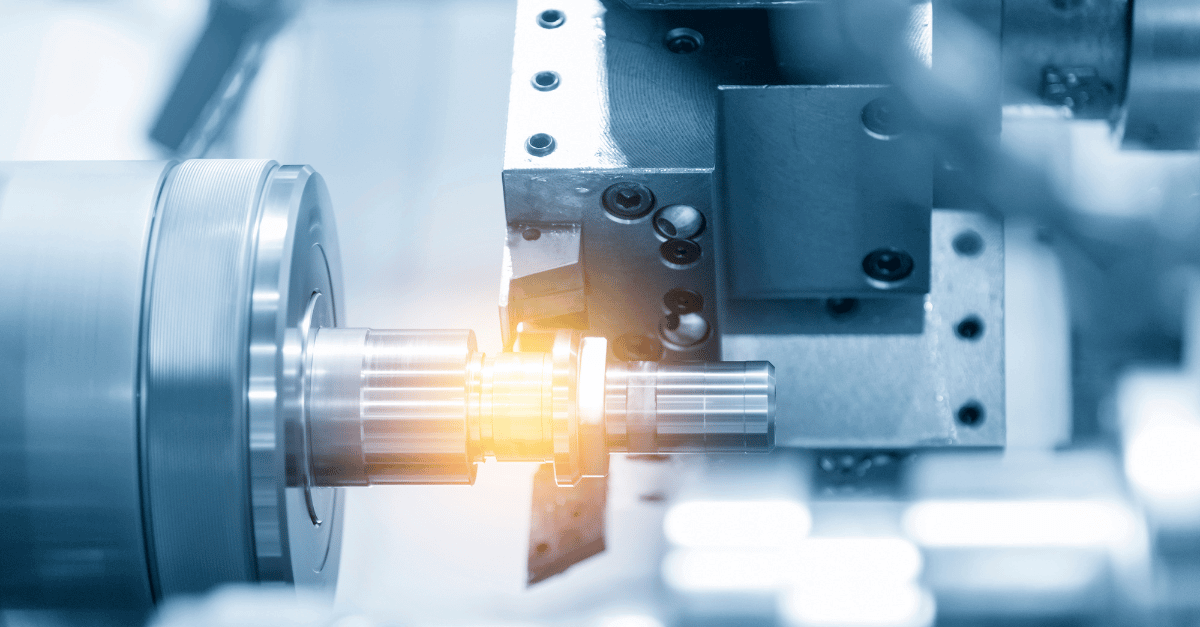

What is Tight Tolerance Machining?

Tight tolerance precision CNC machining refers to advanced manufacturing processes that achieve dimensional accuracies significantly beyond standard capabilities, typically requiring tolerances of ±0.002" (±0.051 mm) or tighter on critical features.

Guide

Download the Tight Tolerance Machining Guide

Learn to apply tolerances strategically for critical aerospace, defense, and medical device applications where lives depend on component performance. Read everything right on page (no form fill required), or get a PDF to keep!

Read the GuideFeatured Articles About Tight Tolerance Machining

What is Considered a Tight Tolerance in Machining? Engineering Standards Explained

Tight tolerance machining explained: ±0.005" standards, when to use them, and cost implications for engineers.

Tight Tolerance CNC Machining Services: Precision Manufacturing Capabilities and Quality Standards

Achieve ±0.0001" CNC machining precision for medical, aerospace & defense. Learn how 1-3 micron accuracy saves lives.

.png?width=1200&height=627&name=Zero%20Tolerance%20Machining%20When%20Perfection%20is%20NonNegotiable%20(1).png)

Zero Tolerance Machining: When Perfection is Non-Negotiable

Discover how zero tolerance machining achieves ±0.00004 dimensional accuracy for aerospace, medical, and semiconductor applications.

Machining Tolerance Chart: Understanding Standard vs. Tight Tolerances for Precision Manufacturing

Master tolerance selection: Engineering guide to ±0.010" standard vs ±0.003" tight machining specifications.

Engineering Tolerance: Design Considerations for Manufacturing Success

Tolerance stack-up giving you nightmares? Engineers reveal when to go tight (and when to stay loose).

Close Tolerance Precision Machining for Critical Applications

Machining tolerances tighter than a human hair width. Here's how engineers actually pull it off.

Standard Machining Tolerances vs. Custom Requirements: Engineering the Right Choice for Mission-Critical Applications

Specifying ±0.002" when ±0.010" works? Engineers reveal the costly tolerance trap most designers fall into.

.png?width=1200&height=627&name=Tight%20Tolerance%20Manufacturing%20(1).png)

Tight Tolerance Manufacturing: Processes and Quality Control for Precision Engineering

When ±0.010" isn't tight enough: Engineers achieving micron-level precision reveal their costly secrets.

CNC Machine Tolerance Capabilities: Understanding What Your Shop Can Deliver

Your ±0.005" spec just tripled machining costs. Engineers reveal when standard ±0.010" tolerances work fine.

Tight Tolerance Machined Parts: Design for Manufacturing Guidelines

Tight tolerance trap: Engineers reveal when ±0.001" costs 8x more but delivers zero extra function.

.png?width=1200&height=627&name=Tight%20Tolerance%20Machined%20Parts%20(1).png)

Complex Tight Tolerance Precision CNC Machining for Medical Device Excellence

From ±0.010" to ±0.0005": Master medical device CNC machining so precise, it makes Swiss watches look sloppy.

Close Tolerance Thermoplastic Machining for Medical Applications

When microns matter more than your morning coffee: close tolerance thermoplastic machining for medical devices that save lives.

Tolerance Tool & Engineering: Measurement and Verification Strategies

Tolerance tool & engineering guide: Because 'eyeballing it' doesn't work for pacemakers. Master precision verification.

The Hidden Cost of Tight Tolerance: Why 'Tighter' Isn't Always Better in Manufacturing

Learn why engineers' default to tight tolerances can increase manufacturing costs by 2-24x without functional benefit.

Tolerance in Product Design: How to Avoid Stack-Up Nightmares and Manufacturing Failures

Tolerance in Product Design: How to Avoid Stack-Up Nightmares and Manufacturing Failures

Case Study

Building a 10-Year Partnership with a DOD‑Telecom Partner

Learn how investment in building strong relationships and robust quality processes, systems and technology have driven a long-term relationship and supported the strategic growth of this telecommunications company.

See HowSubmit Your Design

Get Design Feedback from Our Team

Have a design that needs feedback? Get in touch with our engineering team today to get real-time feedback on how to make your design more effective and manufacturable.

Submit a Design

Get Started

Speak to an Engineer Today

Don’t take our word for it. Reach out and speak to one of our engineers about your part today and see the benefits for yourself. We strive to turn all quotes around 48 hours or less to get your part moving as quickly as possible.

Submit a Design