Hypersonics Electronic Manufacturing: Finding the Right Partner for Sub-Assemblies and Components

November 13, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Extreme environments demand specialized expertise: Hypersonic systems operate above Mach 5, creating temperatures exceeding 1,000°C (1,832°F) and plasma sheaths that disrupt RF communications

- Vertical integration accelerates timelines: Consolidating CNC machining, FIP dispensing, coatings, and thermal assembly under one roof reduces lead times by weeks

- Compliance is non-negotiable: CMMC Level 2 and DFARS certification protect sensitive designs while enabling defense contract eligibility

- Thermal management determines success: Heat flux exceeding 1 kilowatt per square centimeter requires precision-engineered thermal interface materials

- Engineering depth matters: More than 10% engineering staff ensures design for manufacturability feedback that prevents costly redesigns

Hypersonic systems present unprecedented challenges for electronics manufacturers. Traveling at speeds exceeding Mach 5 creates surface temperatures above 1,000°C (1,832°F), acceleration forces surpassing 50 G, and plasma sheaths that block RF communications. Protecting electronics in these extreme environments demands hypersonics manufacturing companies with proven expertise in thermal management, RF shielding, and environmental sealing for Mach 5+ systems.

This guide covers the critical manufacturing processes for hypersonics electronic manufacturing, including precision metalwork, RF shielding systems, form-in-place gasket dispensing, and thermal management solutions. Engineers developing hypersonic sub-assemblies will discover how vertical integration, compliance certifications, and engineering depth accelerate development while ensuring component reliability under extreme conditions.

Essential Background Reading:

- Understanding EMI in Military and Aerospace Electronics: Foundational electromagnetic interference concepts for defense applications

- Complete CNC Machining Engineering Guide: Tolerance capabilities, material selection, and design considerations for precision metalwork

- Thermal Management Applications Overview: Core concepts in thermal dissipation and heat flow engineering

- Defense Supply Chain Management Guide: CMMC requirements and quality standards for defense contractors

Manufacturing for Environments Beyond Conventional Aerospace

Hypersonic vehicles face conditions that destroy conventional components. Traveling at speeds above Mach 5 generates surface temperatures exceeding 1,000°C (1,832°F) through atmospheric friction. Shock waves subject electronics to acceleration forces above 50 G. Plasma sheaths form around the vehicle, creating electron densities that block RF communications.

These challenges demand hypersonic manufacturing partners who understand interconnected thermal, electromagnetic, and structural systems for extreme environments. A machined housing needs thermal coatings, precision-dispensed gaskets, and integrated thermal management — all engineered to work together across extreme temperature swings.

Hypersonics electronic manufacturing requires more than isolated capabilities. The thermal expansion of a 100 mm (4 in.) aluminum housing experiences 0.23 mm (0.009 in.) dimensional change across a 100°C (212°F) temperature swing. Engineers must account for these movements in tolerance budgets, seal design, and component integration across the entire sub-assembly.

Metalwork and CNC Machining: Precision Under Pressure

Hypersonic electronics housings must maintain dimensional stability while dissipating intense heat. Material selection balances thermal conductivity, weight constraints, and operating temperature limits for mission-critical performance.

CNC machining delivers the precision required for hypersonic applications. Standard tolerances of ±0.25 mm (±0.010 in.) enable rapid prototyping and production efficiency. Tighter tolerances remain available when functional requirements demand it, with appropriate lead time consideration for mission timelines. When evaluating vendors, choosing the right custom metal manufacturing partner requires assessment of CNC capabilities, material expertise, and quality systems.

CNC Machining Capabilities for Hypersonic Applications:

- Aluminum 6061 housings: Excellent thermal conductivity with low density for weight-critical applications

- Nickel superalloys: Superior high-temperature performance where thermal extremes exceed aluminum limits

- Five-axis machining: Complex geometries in single setups maintain precise feature relationships

- Standard tolerances: ±0.25 mm (±0.010 in.) enable rapid prototyping and production efficiency

- Tighter tolerances available: Custom precision when functional requirements demand it

Thermal expansion significantly impacts hypersonic housing design. Aluminum expands approximately 23 micrometers per meter per degree Celsius. Engineers must account for these movements in tolerance budgets and seal design to ensure sub-assembly performance throughout the thermal envelope.

Material | Thermal Conductivity | Density | Max Operating Temp | Primary Application |

Aluminum 6061 | 167 W/mK | 2.70 g/cm³ | 200°C (392°F) | Weight-critical housings |

Nickel superalloys | 11-25 W/mK | 8.2-8.5 g/cm³ | 1,000°C+ (1,832°F+) | Extreme thermal zones |

Copper alloys | 200-400 W/mK | 8.9 g/cm³ | 400°C (752°F) | Maximum thermal dissipation |

RF Shielding: Protecting Electronics in Plasma Environments

Plasma sheaths surrounding hypersonic vehicles create unique electromagnetic challenges for electronic systems. Electron densities exceeding 10²⁰ m⁻³ reflect RF signals below the plasma frequency. Shielding must protect electronics while maintaining performance through extreme thermal cycling that occurs during hypersonic flight.

Form-in-place gasket dispensing creates electrically conductive seals on complex geometries. Automated robotic systems place material precisely along defined paths, ensuring continuous conduction even as materials expand and contract during thermal cycles. For engineers designing shielding systems, custom RF shield manufacturing partners must demonstrate integrated FIP dispensing, CNC machining, and specialized plating capabilities.

RF shielding effectiveness depends on material selection and geometric precision. Hypersonics electronic manufacturing requires materials that maintain conductivity above 200°C (392°F) continuous operation while resisting thermal degradation.

Hypersonic RF Shielding Requirements:

- High-temperature materials: Maintain conductivity above 200°C (392°F) continuous operation

- Thermal stability: Compression resilience through repeated thermal cycles

- Plasma frequency consideration: Multi-layer approaches for frequency-specific attenuation

- Geometric precision: Automated FIP dispensing maintains seal integrity on intricate designs

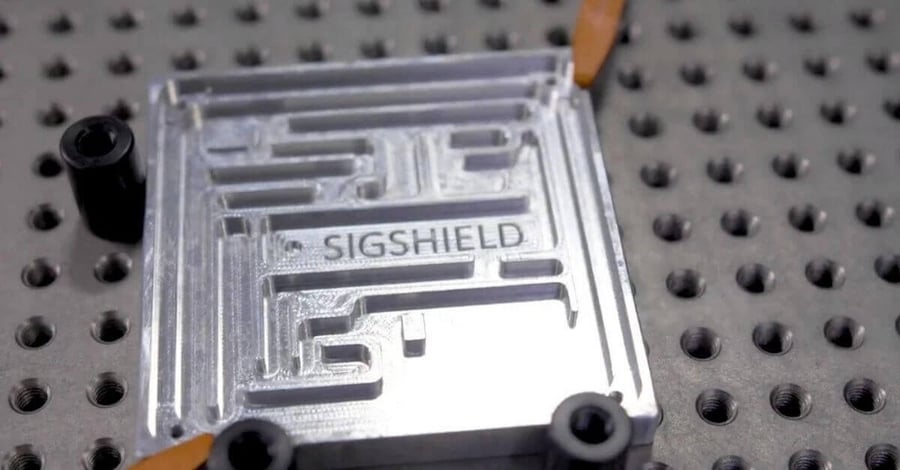

The SigShield™ process integrates all RF shield manufacturing under one roof. CNC machining creates the housing, specialized platings enhance conductivity, FIP gaskets provide electromagnetic sealing, and thermal materials are assembled — reducing coordination delays by weeks compared to multi-vendor approaches that fragment the manufacturing workflow.

Form-in-Place Gaskets: Sealing at Temperature Extremes

Environmental sealing faces unprecedented challenges in hypersonic applications. Gaskets must maintain compression across temperature ranges exceeding 300°C (572°F) while resisting oxidation and mechanical erosion from high-velocity airflow during flight operations.

FIP technology bonds gaskets directly to housing surfaces, eliminating alignment issues inherent in pre-cut designs. Material selection depends on thermal zone, compression requirements, and electromagnetic shielding needs specific to each hypersonic sub-assembly.

Gasket compression changes significantly across thermal operating ranges. A gasket designed for 25% compression at room temperature may experience compression exceeding 40% at elevated temperatures encountered during hypersonic flight. Engineers must model these states to ensure sealing force throughout the thermal envelope without exceeding material stress limits.

FIP Gasket Material Selection for Hypersonic Systems:

- Parker CHO-SEAL 1298: Combined EMI shielding and sealing to 200°C (392°F) continuous

- Ceramic-filled silicones: Environmental sealing above 300°C (572°F) in extreme thermal zones

- Nickel-coated conductive foams: Broad frequency shielding with compression resilience through thermal cycles

- Silver-filled silicones: Maximum conductivity and thermal stability for critical RF applications

Standard FIP bead tolerances of ±0.15 mm (±0.006 in.) provide the precision required for effective electromagnetic sealing. Automated dispensing systems maintain this precision across complex geometries without the variation inherent in manual assembly processes.

Read our Form-in-Place Gasket Guide.

Thermal Management: Engineering Heat Flow Under Extreme Conditions

Heat flux in hypersonic leading edges can exceed 1 kilowatt per square centimeter. Thermal interface materials must maintain conductivity while conforming to surface irregularities that occur during thermal cycling in hypersonic flight environments.

Gap filler pads compensate for surface variations and thermal expansion mismatches between mating components. Material selection balances thermal conductivity against conformability based on application-specific gap sizes and compression forces encountered during assembly and operation.

Thermal management determines component reliability in hypersonics electronic manufacturing. Phase-change materials offer alternative approaches for specific thermal zones. These materials transition from solid to liquid at defined temperatures, flowing to fill microscopic gaps that increase thermal resistance.

Thermal Solution | Conductivity | Temperature Range | Best Application |

Gap filler pads | 1-15 W/mK | -55°C to 200°C (-67°F to 392°F) | Conformable interfaces with surface variations |

Phase-change materials | 3-8 W/mK | -40°C to 125°C (-40°F to 257°F) | Low-pressure reflow applications |

Graphite thermal pads | 5-25 W/mK | -40°C to 400°C (-40°F to 752°F) | High-temperature minimal compression zones |

Ceramic compounds | 3-10 W/mK | -50°C to 300°C (-58°F to 572°F) | Electrically isolating thermal interfaces |

Thermal Management Manufacturing Capabilities:

- Die cutting: Production volumes of thermal pads with consistent dimensional control

- CNC cutting: Rapid prototyping and complex geometries without hard tooling

- Waterjet cutting: Intricate patterns in materials sensitive to die cutting forces

- Laminating: Multi-layer thermal assemblies with adhesive integration

Selection depends on operating temperature ranges and applied compression forces specific to each hypersonic sub-assembly. Engineering teams must evaluate thermal pathways across the complete assembly rather than isolated component specifications.

Related Content:

- Advanced Metal Manufacturing for Aerospace and Defense: Precision techniques for mission-critical components

- EMI Shielding Considerations for Space Applications: Extreme environment shielding design principles

- Defense Thermal Management Meeting Military Standards: Mil-spec compliance and testing requirements

- High-Temperature Gasket Performance in Military Environments: Material selection for extreme temperature applications

- Advanced Aerospace Coatings Engineering Guide: Thermal control and optical coating technologies

Coatings: Thermal Control Through Surface Engineering

Thermal control coatings manipulate radiative heat transfer in hypersonic systems. Black coatings with high emittance radiate heat efficiently in vacuum environments encountered at altitude. White coatings with low solar absorptance minimize heat absorption from solar radiation during flight profiles.

Coating application must account for thermal expansion mismatches between coating and substrate. Coefficient of thermal expansion differences create stress during temperature cycling that can cause delamination without appropriate material selection or stress-relief interlayers.

Coating Solutions for Hypersonic Thermal Management:

- High-emittance black coatings: Efficient heat radiation for thermal dissipation in vacuum

- Low-absorptance white coatings: Solar radiation protection for sun-exposed surfaces

- Electrically conductive coatings: Combined EMI shielding and thermal management

- Space-qualified formulations: Long-term emittance stability with atomic oxygen resistance

Coating selection affects overall thermal management strategy. Engineers must consider emittance values, thermal cycling performance, and adhesion characteristics when integrating coatings into hypersonic sub-assemblies alongside other thermal management approaches.

Read our Guide to Optical and Thermal Coatings.

Converting: Precision Components from Advanced Materials

Converting transforms sheet materials into precision components for hypersonic sub-assemblies. Process selection depends on material properties, production volumes, and geometric complexity required for mission-specific applications.

Standard converting tolerances vary by material classification. Film materials under 6.3 mm (0.25 in.) thickness achieve ±0.25 mm (±0.010 in.) for dimensions under 25 mm (1.0 in.). Dense materials in the same thickness range require ±0.38 mm (±0.015 in.). These tolerances guide design decisions while maintaining manufacturability for hypersonics electronic manufacturing.

Converting Process Capabilities:

- Die cutting: Cost-effective production volumes with consistent repeatability

- Waterjet cutting: Materials sensitive to die cutting forces with intricate geometry requirements

- CNC knife cutting: Rapid prototyping without hard tooling investment

- Laminating: Multi-layer assemblies integrating adhesives and functional materials

Process selection impacts component performance and production timelines. Die cutting delivers cost-effective production volumes. Waterjet cutting accommodates materials sensitive to compression forces. CNC knife cutting enables rapid iteration without tooling delays that extend development schedules.

CMMC and DFARS: Securing the Supply Chain

Defense hypersonic programs demand rigorous cybersecurity and supply chain compliance. CMMC Level 2 certification demonstrates implemented security practices protecting Controlled Unclassified Information throughout the manufacturing process for sensitive defense applications. For defense contractors navigating compliance requirements, finding the right CMMC certified manufacturing partner requires verification of implemented security controls and network architecture.

DFARS compliance affects material selection for machined components and certain elastomeric materials. Specialty metals must be melted or produced domestically or in qualifying countries. Established supply chains ensure material traceability and compliance documentation required for defense contract eligibility. Understanding what DoD contractors should expect from a manufacturing partner includes CMMC certification, DFARS compliance, and quality system implementation.

Modus Advanced Compliance Certifications:

- CMMC Level 2: Network security, access controls, and incident response protecting sensitive designs

- DFARS 252.225-7014: Specialty metals sourcing from United States or qualifying countries

- ITAR Registration: Export control compliance for defense articles and technical data

- AS9100 Certification: Aerospace quality management with configuration control and traceability

Compliance requirements extend beyond certifications. Manufacturing partners must demonstrate implemented controls rather than planned future compliance. Security posture affects program eligibility and contract award decisions for defense hypersonic programs.

Vertical Integration: Reducing Risk and Accelerating Timelines

Hypersonic development timelines demand manufacturing approaches that compress lead times without compromising quality. Consolidating multiple processes under one roof eliminates vendor coordination delays while enabling integrated engineering review across all manufacturing stages.

The SigShield™ vertically integrated process demonstrates this approach. A single engineering team reviews designs across CNC machining, specialized coatings and platings, FIP gasket dispensing, and thermal material assembly. Changes implement across processes without re-coordinating between multiple vendors. However, choosing the wrong manufacturing partner leads to quality control issues, extended lead times, and costly redesigns that delay critical programs.

SigShield™ Vertically Integrated Process:

- CNC machining: Precision metal housing fabrication with complex geometries

- Specialized coatings and platings: Thermal control and conductivity enhancement

- FIP gasket dispensing: Automated precision dispensing on intricate designs

- Thermal material assembly: Converted thermal interface materials and RF absorbers integrated into complete sub-assemblies

Quality control spans the complete manufacturing sequence rather than inspecting only final assembly. Engineering support throughout the product lifecycle proves essential for hypersonics electronic manufacturing. Rapid prototyping enables design validation without tooling investments. Quick-turn capabilities support design iterations as requirements evolve. Production processes scale efficiently from prototype to volume manufacturing.

Selecting Your Manufacturing Partner

Hypersonic component manufacturing requires evaluating partners across multiple dimensions. Technical competence in individual processes matters, but integration capability and engineering depth often determine program success for mission-critical applications. Whether developing component manufacturing capabilities for hypersonic missile systems operating in extreme thermal and electromagnetic environments or hypersonic aircraft component manufacturing requiring precision metalwork and advanced thermal management, partner selection determines program success.

Material partnerships with suppliers like Parker Chomerics, Laird, and Henkel provide access to proven materials with documented performance in extreme environments. Understanding how materials behave during processing prevents manufacturing issues that compromise component performance. For defense contractors working with US hypersonic weapons manufacturers on sub-assembly and component partnerships for advanced weapon systems, supply chain security and technical capability must align.

Critical Partner Evaluation Criteria:

- Engineering expertise: More than 10% engineering staff for meaningful design for manufacturability feedback

- Material knowledge: Supplier relationships providing access to space-qualified and high-temperature materials

- Quality systems: AS9100 certification with precision measurement technology for verification

- Security posture: Implemented CMMC Level 2 controls, not planned future compliance

- Vertical integration: Multiple processes under one roof reducing lead times and coordination risk

Quality systems must demonstrate more than standards compliance. Measurement technology including Zeiss CMMs, Keyence laser profilometers, and Micro Vu vision systems enables precision verification across diverse component types specific to hypersonics electronic manufacturing.

Engineering collaboration optimizes designs for both performance and manufacturability. Design for manufacturability reviews identify potential issues before production begins. Material selection guidance draws from experience with similar applications. Tolerance analysis ensures designs remain manufacturable while meeting functional requirements.

See It In Action:

- Space-Critical Components Manufacturing Case Study: Real-world example of extreme environment component production

- Custom RF Shield Manufacturing Partner Selection: How to evaluate capabilities for complex shielding projects

- CNC Parts with FIP Gaskets - Vertical Integration Advantages: Real examples of integrated manufacturing benefits

- Quick-Turn RF Shielding Case Study: Accelerated development using integrated capabilities

Frequently Asked Questions: Hypersonics Electronic Manufacturing

What temperatures do hypersonic electronics need to withstand?

Hypersonic electronics housings must protect components from surface temperatures exceeding 1,000°C (1,832°F) while internal electronics operate reliably. Heat flux in leading edges can exceed 1 kilowatt per square centimeter. Thermal management systems must dissipate this heat while maintaining acceptable internal temperatures. Material selection, thermal interface materials, and thermal coatings work together to manage these extreme thermal loads throughout the flight profile.

What tolerances are achievable for hypersonic component manufacturing?

CNC machining delivers standard tolerances of ±0.25 mm (±0.010 in.) for aluminum and nickel superalloy housings. Form-in-place gasket dispensing achieves ±0.15 mm (±0.006 in.) bead tolerance. Converting processes for thermal interface materials range from ±0.25 mm (±0.010 in.) for film materials to ±0.38 mm (±0.015 in.) for dense elastomers. Tighter tolerances remain available when functional requirements demand additional precision with appropriate lead time consideration.

Visit the full resource center.

How does vertical integration benefit hypersonic development programs?

Vertical integration consolidates CNC machining, FIP gasket dispensing, coatings, and thermal material assembly under one roof. This eliminates coordination delays between multiple vendors. A single engineering team reviews designs across all processes, implementing changes without vendor re-coordination. Quality control spans the complete manufacturing sequence. Development timelines compress by weeks compared to multi-vendor approaches while maintaining precision required for hypersonic applications.

What compliance certifications are required for defense hypersonic manufacturing?

Defense hypersonic programs require CMMC Level 2 certification for cybersecurity controls protecting Controlled Unclassified Information. DFARS 252.225-7014 compliance ensures specialty metals sourcing from domestic or qualifying countries. ITAR registration demonstrates export control compliance. AS9100 certification provides aerospace quality management with configuration control. These certifications must be implemented, not planned, to qualify for defense contract eligibility.

How do plasma sheaths affect RF communications in hypersonic flight?

Plasma sheaths form around hypersonic vehicles, creating electron densities exceeding 10²⁰ m⁻³. These densities reflect RF signals below the plasma frequency, blocking communications. RF shielding systems must protect internal electronics while maintaining signal transmission through specialized apertures. Form-in-place gaskets create continuous electrical paths that prevent signal leakage. Material selection must maintain conductivity through thermal cycling while providing environmental sealing against plasma exposure.

Next Steps:

- Complete Form-in-Place Gasket Design Guide: Deep dive into FIP dispensing for extreme environments

- SigShield Vertically Integrated Manufacturing Process: Explore the integrated approach to RF shield production

- CMMC Compliant Build-to-Print Manufacturing: Path to defense contract compliance

- Vertical Integration Benefits for Complex Assemblies: How consolidation accelerates development timelines

- Complete Guide to Machining Tolerances: Engineering reference for precision manufacturing capabilities

Partner with Engineering Depth for Mission Success

Hypersonic systems protect service members and enable critical missions in contested environments. Your components must perform flawlessly under conditions that destroy conventional designs in seconds.

Manufacturing partners must understand interconnected thermal, electromagnetic, and structural challenges specific to hypersonics electronic manufacturing. Engineering collaboration optimizes designs for both performance and manufacturability. Vertical integration reduces lead times while maintaining the precision that mission success demands.

When lives depend on your hypersonic technology, every day of accelerated development matters. Partner with a team that shares your commitment to excellence and understands what's at stake. Submit your designs for engineering review and discover how integrated manufacturing capabilities can accelerate your program while ensuring component reliability under the most extreme conditions.