Guide

RF Shielding: Everything You Need to Know

The team at Modus Advanced has put together this guide to RF shielding to help you understand how to select materials and design for RF shielding applications.

Download PDF.png?width=1024&height=768&name=Pillar%20Hero%20%20RF%20Shielding%20Guide%20(1).png)

Key Points

Key Points

- Because sources of radiofrequency (RF) interference are growing, RF shielding is a key engineering consideration in a growing number of fields.

- There are multiple materials, manufacturing methods and approaches related to RF shielding.

- Approaching your design with a solid understanding of RF shielding and the assistance of an expert manufacturing partner will make the design and manufacturing process go much more smoothly.

From bustling city centers to remote mountain peaks, electromagnetic signals are everywhere. These energy-carrying waves keep much of our modern world moving and functioning as it should. But they are also disruptive.

In terms of human history, the advent of manmade radiofrequency (RF) signals is relatively new. But the sheer number of signals hopping from one point on the globe to another has proliferated in a way that almost no one could have seen coming. Now, these signals are everywhere and touch everything. That has created the problem of RF interference.

People are problem-solvers, so this problem has brought about a solution. It’s called RF shielding. This technique is now a key consideration in engineering, design and manufacturing in a wide variety of industries.

And as the problem of RF interference becomes more common, the number of industries in which RF shields are common grows, too.

RF shielding is an elegant solution to the problem, but it is an advanced engineering concept. And designing an RF shield that will work in the real world, from manufacturability to functionality, is no easy task But the Modus Advanced team is here to help. That’s why we have created the RF shielding guide. Read on to learn everything you need to know about this complex and important topic.

Modus Advanced creates some of the highest-quality RF shields available today. Whether you’re a defense contractor, a consumer electronics designer or somewhere in between, we can manufacture the perfect RF shield for your needs. Contact us.

Don't have time to read this? Take a copy with you:

Download PDF- 1Overview

- 2Why Shield Against RFI?

- 3Sources of RFI

- 4How RF Shielding Works

- 5Types of RF Shields

- 6RF Shields vs. RF Absorbers

- 7Applications for RF Shielding

- 8RF Shield Manufacturing Methods

- 9Materials Used in RF Shielding

- 10Choosing an RF Shield Manufacturing Partner

- 11Work With a Leader in RF Shield Manufacturing

- 12Related Content

- 13Download this Guide

- 1Overview

- 2Why Shield Against RFI?

- 3Sources of RFI

- 4How RF Shielding Works

- 5Types of RF Shields

- 6RF Shields vs. RF Absorbers

- 7Applications for RF Shielding

- 8RF Shield Manufacturing Methods

- 9Materials Used in RF Shielding

- 10Choosing an RF Shield Manufacturing Partner

- 11Work With a Leader in RF Shield Manufacturing

- 12Related Content

- 13Download this Guide

Table of Contents

Select Your Chapter

Chapter 1

Overview

What Is RF Shielding?

RF shielding is the act of shielding a device from radio frequency interference (RFI). That’s the definition in its simplest form, but in practical terms, this usually means designing an enclosure that protects a particular part of a device from interference from RF signals. This enclosure is usually made from a metal housing and gaskets, O-rings and similar smaller parts made from RF-resistant materials.

RF Shielding vs. EMI Shielding

Often referred to as radiation shielding, RF shielding is not always the same thing as electromagnetic interference (EMI) shielding, although both tasks involve shielding sensitive devices from interference from errant signals. The key difference lies within the range of frequencies you are shielding against. RF shielding involves shielding a device from signals that are within the range of frequencies used for radio transmission. EMI shielding involves shielding against higher frequencies that are used for applications well beyond radio transmission. Both types of signals can interfere with electronic devices, and many devices need to be shielding from both. That is why you often hear the terms RF shielding and EMI shielding used interchangeably, but they are not exactly the same thing.

Chapter 2

Why Shield Against RFI?

We know that RF signals can interfere with certain electronic devices, but what does that interference look like, exactly? It can look a lot of different ways, causing problems that range from the relatively benign to the life-threatening.

Without proper RF shielding, certain electronic cables can lose their signals to signal escape, which degrades information passing along the device’s circuits. That’s a problem, but it is likely to cause little more than signal distortion and frustration. A similarly entry-level RF shielding application can be found in a standard microwave oven. The inside of the microwave’s metal enclosure forms a Faraday cage — a classic type of RF shield — that prevents radiation from escaping the device and reaching users.

However, the reasons to shield against RFI go much deeper and become much more serious than that. For example, RF signals can be used to steal access to radio-frequency identification (RFID) chips used in biometric passports and many other devices. Additionally, RF signals can interfere with cellular networks used for all kinds of communication, as well as medical devices like MRI machines.

Interference from RF signals can cause devices of all kinds to malfunction. That means that anyone engineering an electronic device has reason to be concerned about RF interference and take action to protect their device.

Case Study

Building a 10 Year Strategic Relationship

See how Modus has redefined the traditional supplier relationship and supported the strategic growth of this DoD telecommunications company.

See HowChapter 3

Sources of RFI

Where does RFI come from? As it turns out, it comes from all kinds of places. While human beings didn’t invent radio signals, they did discover them and learn how to harness and create them. That’s why we now have to contend with both natural and man-made radio signals.

Natural RF Signals

Natural RF signals come primarily from weather events, such as lightning strikes, snowstorms and dust storms. Other natural causes of RF signals include static electricity, solar flares and cosmic noise.

Man-Made RF Signals

Man-made RF signals can be either intentional or unintentional, but regardless of the intent behind them, they can disrupt nearby electronic devices.

Unintentional man-made RFI can come from power transmission lines, generators, electric motors and similar devices. Intentional RFI doesn’t always have malicious intent behind it, but it can be used to jam radar systems and intentionally interfere with aerospace and defense equipment. Less malicious intentional RFI can come from radar systems, satellites and radio transmitters.

Resource Center

EMI Shielding Solutions for Aerospace & Defense Resource Center

All your EMI Shielding resources have been organized in one spot to help answer your most common questions regarding EMI shielding in aerospace and defense.

See HowChapter 4

How RF Shielding Works

Radio waves are invisible, fast moving and quite literally everywhere. So how does a relatively simple RF shield block out these interfering signals and keep its associated device running as it should?

These signals carry energy and are conductive, meaning they can be redirected with smart design and the proper use of conductive materials. A well-designed RF shield will effectively block and redirect incoming RF signals away from the device it is meant to protect.

It’s important to understand that RF shielding is not always a matter of protecting devices from radiated signals that are, in effect, flying through the air from some remote place and reaching your device.

While that is a common and necessary consideration for RF shielding, many RF shields are designed to block RFI coming from another part of the same device. Meanwhile, other RF shields are meant to keep RF signals from escaping, rather than blocking them from entering.

As you might imagine, certain materials and even shapes perform better than others in RF shielding. We will discuss RF shield design and materials in a later section of this guide.

Case Study

Vertical Integration

Alleviates Production Delays

Learn more about how Signal Hound was able to overcome six months of production delays by finding a manufacturing partner that offered vertical integration.

Read the Case StudyChapter 5

Types of RF Shields

Devices designed to solve particular problems or innovate in some way often call for 100% custom design and engineering approaches, and that can include RF shields. In other words, there is no limit to the number of types of RF shields. However, several common configurations have been developed over the years. We cover each of those types of RF shields below.

Faraday Cages

Named for their inventor, English scientist Michael Faraday, Faraday cages — sometimes called Faraday shields — use a conductive wire mesh to create an enclosure that blocks RF signals from entering. The wire mesh of the enclosure works to distribute external signals around the surface area of the cage in an even way, allowing no part of the signal to enter the interior of the cage.

Gaskets

RF-shielding gaskets are often part of a larger RF shield rather than RF shields themselves, but their function is the same as any other RF shield: prevent RF signals from entering a particular part of a device.

Gaskets that can block out RFI are usually made with a silicone base material that is filled with conductive metal particles. The particles reflect incoming RF signals to prevent them from passing through the gasket.

Gaskets are often found around openings of Faraday cages or solid RF-shielded enclosures. They fill the gap space between the opening and its door.

O-Rings

O-rings are highly similar to gaskets when applied to RF shields. They mate one surface to another through an O-shaped opening and are common on all kinds of devices.

While most non-RF-shielding O-rings are made from metal, RF-shielding O-rings are typically — but not always — made from a silicone elastomer that is filled with metal particles meant to conduct incoming RF signals.

Solid Enclosures

Solid enclosures look like their name suggests they would. They are usually solid, continuous metal cases placed around components that are sensitive to RFI.

The design of solid RF-shielding enclosures is meant to minimize openings in order to create an effective shield. However, this creates certain problems that can affect devices with special requirements, such as components that may need to be vented.

Another important consideration for RF-shielding solid metal enclosures is grounding. These enclosures must always be properly grounded to prevent conducted RF from reaching and entering them.

Vent Shields

What do you do when you need to keep a component cool through venting but also shield it from RFI? You design a vent shield. These RF-shielding devices allow air to flow through them but block out offending radio signals that could harm the performance of the protected component.

In much the same way that a Faraday cage has very small holes in its wire mesh but still blocks out RFI, vent shields are designed with conductive metal mesh that contains holes small enough to keep signals of undesirable frequencies out but allow cooling or heated air to pass in or out of the enclosure.

Cable Shields

Cable shields are used on conductive cables to keep external signals from interfering with their own and keep their own signals from escaping and interfering with nearby devices. These RF shields are usually wrapped around the cable from end to end.

Cable shields usually consist of a conductive metal like copper or aluminum, but they can also be made from metal-coated fabrics or conductive polymers. In any case, they can shield a cable in one of three ways:

- In the form of a continuous sheet of foil wrapped around the cables

- In the form of wiring wrapped in a spiraling fashion around the protected cables

- In the form of woven or braided metal wires wrapped around the cables

Board Shields

Board shields are meant to block RFI from entering or leaving circuit boards, chips and similar components. They are very small and usually formed as solid enclosures or Faraday cages sealed with small RF-shielding gaskets.

Shielded Facilities

RF shields don’t have to be small and intricate to work. They can be as big as buildings and still block radiation from entering or leaving.

That’s certainly the case with RF-shielded facilities, which are usually formed like solid enclosures. That is, conductive sheet metals cover the six sides of any shielded room (four walls, floors and ceilings), and RF-shielding fittings cover the gaps between the metal sheets.

Perhaps the most readily available example of an RF-shielded facility is your standard MRI room. To function properly, MRI machines must be shielded from external radio signals, so MRI facilities are typically shielded.

MRI facilities are not the only example of this type of RF shield, however. Any facility that has an interest in protecting against security and data breaches, cyber attacks and espionage may benefit from a facility-wide shield. Examples include military facilities, government buildings, banks and IT operations.

Chapter 6

RF Shields vs. RF Absorbers

As you’re learning about RF shielding and other methods of protecting devices from radiated signals, you’re likely to come across a similar sounding — but functionally distinct — term: RF absorbers.

What is the difference between an RF shield and an RF absorber? An RF shield is a whole device, usually in three dimensions, that encloses and protects a part or component from RF signals. An RF absorber is a piece of conductive, flat sheet stock that doesn’t block RF signals, but absorbs them.

RF absorbers are loaded with magnetic particles that allow desirable signals to permeate them but absorb signals that fall within offending frequencies. RF absorbers are often a part of larger RF shields, as their applications work in conjunction with one another, but they are not the same thing.

Chapter 7

Applications for RF Shielding

RF shields are diverse in their form, manufacturing methods and materials used, and there’s a reason for that: They have extremely wide applicability across industries. Nearly any industry that deals with electronic devices will use RF shields in some form, but some of the industries that use RF shielding most often include the following:

- Electric vehicles

- Telecommunications and satellite communications

- Medical devices

- Defense and aerospace

- Consumer electronics

We discuss each of these industries in more detail below.

Electric Vehicles

The electric vehicle (EV) industry is growing at break-neck pace. That means the need for RF shields for EVs is growing quickly, too.

While all vehicles in the modern age can benefit from RF shielding to prevent interference with on-board navigation, WiFi and similar systems, EVs have double the use for RF shielding. That’s because they rely on electric motors — a primary source of unintentional man-made RFI — to move.

Those motors release RF signals that can then interfere with other systems and components onboard the vehicle. RF shields can prevent those signals from escaping or block them from entering certain enclosures.

Telecommunications and Satellites

To relay radio signals across thousands of miles of atmosphere or even space, telecommunications devices need to be well-protected against interfering signals that could garble messages and prevent them from reaching their destinations. That’s what RF shields are made for.

RF shields are common on cellular towers, 5G cells and satellites. They serve the dual purpose of keeping out external signals and preventing internal signals from interfering with other components on the same device.

Medical Devices

All kinds of medical devices transmit or receive signals that can suffer from RFI. That’s why RF shields are so important in the medical device industry.

We have already covered the example of shielding MRI facilities, but we can get much more granular than that. Consider the humble pacemaker, a cardiac life support device that could malfunction and cause the patient to die if strong radio signals interfere with it. In a similar vein, you have ventilators, computer-assisted surgical equipment and X-ray devices, among others.

Defense and Aerospace

Unlike various other industries that benefit from and routinely use RF shields, the defense and aerospace industries rely on RF shielding to save lives and preserve national security.

That may sound at first like an exaggeration, but consider the case of a passenger airplane that cannot properly communicate with air traffic control due to RFI. Additionally, consider the case of electronic warfare, in which weaponized RF signals may be used to jam radar defense systems.

The list of potential horror stories goes on, with each emphasizing the critical need for high-quality RF shields in the aerospace and defense industries.

Consumer Devices

Defense and aerospace are tough acts to follow, but the consumer electronic device industry may be a contender. It’s not so life-and-death, but the world now operates on cellular networks and WiFi. Disrupt those systems, and the whole world is disrupted.

What keeps those critical systems functioning properly is, in part, RF shielding. Every single WiFi router on the planet is both a small source of RFI and sensitive to RFI. No cellular network would be immune to disrupted signals without shielding. Smart watches, Internet of Things (IoT) devices and a growing number of other products rely on signal transmission that would fall prey to RFI if not for RF shielding.

TURNKEY RF SHIELDS

Learn More About

the SigShield™ Process

Often when manufacturing a product that requires the dispensing of form-in-place gasket, it pays to have a partner who can machine your housing, dispense FIP gaskets, and manufacture other components under one roof.

Learn About SigShieldChapter 8

RF Shield Manufacturing Methods

Because RF shields are complex parts, they require precision during the manufacturing phase. They may also require more than one manufacturing method to complete the various parts of the shield. Below, we discuss the most common RF shield manufacturing methods.

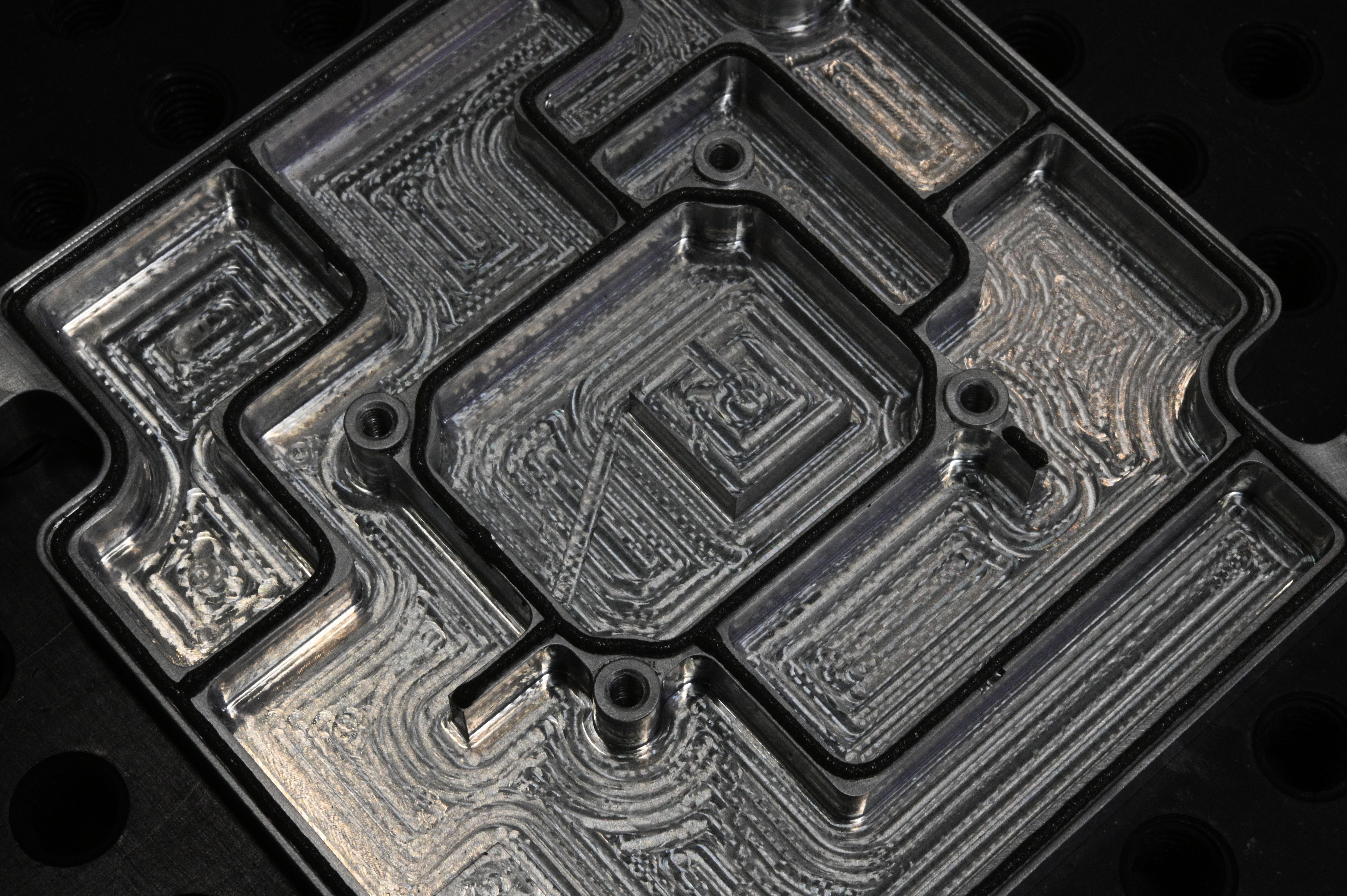

CNC Milling

Computer numerical control (CNC) milling is, in the experience of the Modus team, the most common method for manufacturing RF shields. Modus uses a vertical milling center to machine effective, high-quality RF shields in the vast majority of the RF shield jobs that we take on.

There are a few reasons for that. CNC milling cuts material waste and lead times, which makes it perfect for prototyping and projects that are on tight timelines and budgets. Meanwhile, you don’t have to hard tool with CNC milling, which can cut costs and headaches.

Waterjet Cutting

Although this manufacturing method is less common than CNC milling for manufacturing RF shields, waterjet cutting can be used in RF shielding and sometimes fits the application perfectly. This manufacturing method uses a super-powered jet of water — often mixed with particles of an abrasive material — to cut through materials and shape them to fit the design of the part at hand.

Waterjet machines can cut a wide variety of materials, ranging from metal all the way down to silicone elastomers.

Die Cutting

Die cutting is a manufacturing method usually reserved for softer materials, such as silicone elastomers used in gaskets. Because RF-shielding gaskets are common components of RF shields, this manufacturing method is sometimes used in RF shield production.

Die cutting uses a metal die to cut softer materials into predefined shapes. This method is fast but can be somewhat inefficient when it comes to material waste. However, for mass production of larger and less complicated shielding gaskets, it can fit the bill nicely.

Form-in-Place (FIP) Gasket Dispensing

Form-in-place (FIP) dispensing is among the most common and effective ways to manufacture gaskets for use in RF shields. In FIP dispensing, a dispenser places a liquefied gasket material onto metal or plastic housing, and the material then dries and cures to the housing.

FIP is most useful for very small, intricate and precise gaskets, making it perfect for dispensing RF-shielding gaskets onto RF shields.

Chapter 9

Materials Used in RF Shielding

You're probably wondering what blocks RF signals? And more specifically, what material blocks rf signals? We're glad you asked! High-quality RF shielding is achieved, at least in part, with high-quality materials. Most RF shields will involve at least two different kinds of materials — the material used for the structural housing of the shield and the materials used to make gaskets and O-rings. We cover each of these types of materials below.

Nickel Silver

Nickel silver is actually a copper alloy. It is common in RF shields because of its relatively wide availability, bright silver appearance and natural resistance to corrosion.

Copper

Copper works well in RF shields because it naturally acts as an effective conductor, absorber and attenuator of RF signals. Variations on standard copper, such as beryllium copper, brass and bronze, also find use in RF shields. Most forms of copper are relatively easy to work with and form, but this material can be on the more expensive side of the available RF shielding materials.

Steel

Steel is a ferromagnetic material that creates a natural magnetic shield that you won’t find in many other radio frequency shielding materials. Steel is also quite sturdy, and cold-rolling and hot-rolling can create further distinctions between steel materials’ magnetic and structural properties.

Aluminum

Aluminum is lightweight, making it an ideal RF shielding material where component weight is a concern, such as in aerospace applications. This material often offers a lower price point, but keep in mind that aluminum can be susceptible to galvanic corrosion and is less conductive than other materials.

Elastomers Filled with Conductive Materials

On their own, elastomers like silicone will not protect against radiofrequency interference (RFI). But when you fill them with conductive metal particles, they can act as effective RFI shields. This is how radio frequency shielding is done in gaskets and O-rings — common components of RF shields.

Various filler materials can turn a standard gasket into an RF-shielding gasket. Here are some examples of the most common RF-shielding conductive filler materials:

- Nickel graphite

- Nickel aluminum

- Silver

- Silver copper

- Silver nickel

- Silver aluminum

Like the materials used for the metal housing of an RF shield, the filler materials used in RFI gaskets vary widely in their properties and price points. However, with the wide variety of available materials, finding the right filler material to fit your design and budget should be no issue.

Conductive Fabrics and Foams

While this style of RF shielding material is less popular than many of the others listed here, it is still worth mentioning because it can be a fit for lower-stakes designs with smaller budgets. Instead of RF-shielding gaskets, some RF shields can use conductive fabric materials or even foam sprayed with conductive material.

These RF shielding components fill the same role as gaskets and O-rings, but they can often be less expensive because they use less metal. However, they are often less effective at RF attenuation as a result, and they only work well in applications that involve low closure force.

Chapter 10

Choosing an RF Shield Manufacturing Partner

At this point in our RF shielding guide, you have learned a lot about the nuts and bolts of RF shields — materials, manufacturing processes, types, dynamics and theories and more. What all of that information can’t teach you, however, is how to manufacture an RF shield. That’s because RF shield manufacturing is specialized knowledge that most designers and engineers rely on a manufacturing partner to provide.

But how, exactly, are you supposed to choose your manufacturing partner? There are dozens of RF shield manufacturers who would like your business. And while they will all tell you that they can manufacture your part to your exact specifications, they won’t all be speaking the truth.

So, how do you choose the best manufacturing partner to take on your RF shield? By assessing the following variables in each partner you consider.

Industry Certifications

Certifications aren’t everything in manufacturing, but they are a reliable baseline by which you can assess a potential manufacturing partner. That’s because, at the very least, these certifications take time to get. While they don’t definitively prove that a partner will actually do the job, they do demonstrate a commitment to quality and expertise in manufacturing.

More specifically, you will want to look for ISO 9001 certification. And if your device is going to fall under the aerospace or defense umbrella, you will need to look for the industry-standard AS9100 certification.

Demonstrated Success with RF Shield Manufacturing

Beyond certifications, you need to ensure that you won’t be the first customer the manufacturer has ever manufactured an RF shield for. You probably shouldn’t even be the fifth or the 10th.

In other words, you don’t want to be the test subject — you want to work with a partner who can point to particular devices for which they have successfully manufactured RF shields. All the better if they can provide customer testimonials that relate specifically with their RF shield manufacturing capabilities.

Vertical Integration

The more processes your manufacturing partner can handle in-house, the better for your budget and likely quality of the finished product. That’s the whole concept behind vertical integration — something that is severely lacking in advanced manufacturing settings.

In most scenarios, a part goes to one partner to have the metal housing machined. It is then returned to the customer, who sends it on to the vendor who can dispense the gaskets. Repeat that process for metal coatings and platings and various other parts of the manufacturing process, and you have some hefty freight costs on your hands, as well as a fair number of headaches.

But if you can find a high-quality RF shield manufacturer who can handle several of those steps all at once, you pay less in shipping. Also, your to-do list becomes shorter, and you have less to worry about when it comes to miscommunications between the various manufacturing vendors who might otherwise be involved in the building of your RF shield.

On-Staff Manufacturing Engineers

Your team may have some of the most talented engineers you have ever known, but that doesn’t guarantee that you have a manufacturing expert on hand. In fact, it would be surprising if you did — manufacturing is a subject that is rarely covered in engineering school and one that is typically picked up over the course of a career.

And when you’re designing something to be manufactured, it’s incredibly helpful if you can approach it with some expertise on the manufacturing side. That’s why it is so important to find a manufacturing partner who has engineers on staff. These engineers should be able to advise you about the manufacturability of your RF shield and related parts to make sure you aren’t over-spending or designing something that is impossible to manufacture.

A Robust Quality System

If you don’t have quality, you might be left with an unusable or ineffective RF shield. If that shield is defective or malfunctions out in the real world, the blowback comes back to you — not the manufacturer who actually messed it up.

That’s why you need to look for a manufacturing partner who has built a robust quality system. Look for stated goals on quality percentages, documented processes for preventing, mitigating and correcting errors and modern technology.

Additionally, the manufacturing partner should have a quality department staffed by quality engineers and other professionals whose job it is to ensure that your RF shield is manufactured to the highest degree of quality possible.

A Collaborative Approach

While the process of having your RF shield manufactured is transactional, you will want a manufacturing partner whose approach is collaborative. In advanced manufacturing settings, collaboration is key to preventing errors, spotting potential design problems and hitting deadlines without unnecessary delays.

To assess a potential manufacturing partner’s ability and willingness to collaborate with you as a customer, all you have to do is ask them to describe their process for each customer. It should involve several touch points with you, a consultative approach to assessing your design and planning its manufacturing and various points at which you can offer feedback.

Chapter 11

Work With a Leader in RF Shield Manufacturing

From both an engineering and manufacturing perspective, RF shielding is a complicated topic. You have to design an effective shield that is possible and efficient to manufacture; you have to select the right manufacturing methods and materials; and you have to find a manufacturing partner who can actually get the job done and done right.

Here’s how Modus Advanced solves each of those problems for customers in aerospace, defense, medical technology, telecommunications and a wide variety of other industries:

- We offer our unique Design for Manufacturability (DfM) review, in which our experienced staff engineers offer actionable feedback on your design as it relates to the manufacturing process.

- With access to the highest-quality materials and diverse manufacturing capabilities, we can help you select a manufacturing method and set of materials that will fit both your device’s intended use and your project’s budget.

- With vertically integrated processes, all the relevant industry quality certifications, on-staff quality engineers and unmatched customer service, we get your project done on time, on budget and perfectly within spec — every time

It’s our job to solve these problems for you. We’ve done it successfully for countless customers in an enormous number of industries. If you have RF shielding needs, we have RF shield manufacturing solutions that will really work for you

Chapter 12

Related Content

- RF Shielding Material Guide

- What is EMI/RFI Shielding?

- What DoD Contractors Should Expect from a Manufacturing Partner

- RF Blocking: RF Shields vs. RF Absorbers

- RF Shield Design Guide

- RF Shields: Why a Vertically Integrated Partner is Best

- 5 Manufacturing Methods for Shielding RF Signals

- The Best Process for Building a Custom RF Shield

- RF Shielding Solutions: A Breakdown of Modus's Capabilities

- RF Absorbers for Military Applications

- What is RF Shielding Effectiveness?

- 8 RF Shielding Techniques to Know About

Don't have time to read the entire guide now?

Fill out the form to get a downloadable PDF version of the guide to save so you can read it later.

Get Started

Speak to an Engineer Today

Don’t take our word for it. Reach out and speak to one of our engineers about your part today and see the benefits for yourself. We strive to turn all quotes around 48 hours or less to get your part moving as quickly as possible.

Submit a Design.png?width=1024&height=768&name=Telecommunciations%20(1).png)

.jpg?width=1200&height=627&name=_high%20electrical%20conductance%20thermal%20control%20coating%20(1).jpg)