Choosing the Right Hypersonic Manufacturing Partner: Engineering Solutions for Extreme Environments

November 13, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Thermal management capabilities: Partners must handle temperatures exceeding 1648°C (3000°F) through advanced materials and coating expertise

- Multi-process integration: Vertically integrated hypersonic manufacturing reduces supply chain complexity and accelerates development timelines

- Compliance infrastructure: CMMC Level 2 and DFARS compliance protect sensitive defense data throughout manufacturing

- Material expertise: Access to superalloys, carbon composites, and high-temperature elastomers enables components that withstand hypersonic flight conditions

- Engineering support: Design for manufacturing guidance prevents costly redesigns and ensures manufacturability at scale

The Hypersonic Manufacturing Challenge

Hypersonic systems represent one of the most challenging engineering frontiers in modern defense technology. Components traveling at Mach 5 and beyond encounter environmental extremes that push conventional manufacturing to its limits. RF shields must maintain electromagnetic integrity while enduring surface temperatures approaching 1648°C (3000°F).

The Department of Defense has identified hypersonic weapons as a critical technology area requiring immediate industrial base expansion. Engineers developing hypersonic weapons systems that operate beyond Mach 5 need manufacturing partners who bring together multiple specialized processes, advanced materials knowledge, and quality systems designed for defense applications. Selecting the right hypersonic manufacturing partner determines whether your components survive the extreme thermal cycling, vibration loads, and electromagnetic requirements of sustained flight beyond Mach 5.

Essential Background Reading:

- Aerospace & Defense Manufacturing: Understand the broader landscape of defense manufacturing before diving into hypersonic-specific requirements

- RF Shielding Fundamentals: Learn the basics of electromagnetic interference protection in defense systems

- Quality Management Systems: Explore AS9100 and defense quality standards that underpin hypersonic manufacturing

- CMMC Level 2 Overview: Get foundational knowledge of cybersecurity requirements for defense contractors

Critical Hypersonic Component Requirements

Hypersonic flight environments demand materials and manufacturing processes far beyond conventional aerospace standards. Whether you're developing hypersonic missile components that withstand extreme flight conditions or hypersonic aircraft systems designed for sustained high-speed flight, components experience sustained temperatures between 538°C and 1093°C (1000°F to 2000°F) across most surfaces, with leading edges reaching significantly higher temperatures.

Environmental challenges include:

- Extreme thermal cycling: Surface temperatures from cryogenic cold to 1648°C (3000°F) or higher

- High vibration loads: Acoustic and mechanical stresses exceeding conventional aerospace standards

- Size and weight constraints: Reduced SWaP requirements demand compact, lightweight solutions

- Electromagnetic performance: RF shielding must maintain effectiveness across temperature extremes

Standard aluminum alloys lose structural integrity above 204°C (400°F). Conventional polymers and elastomers degrade rapidly under sustained thermal cycling. Every component must meet performance requirements while contributing to overall system goals.

Essential Hypersonic Manufacturing Capabilities

Hypersonic component manufacturing demands multiple specialized processes working in coordination. Single-capability suppliers create supply chain complexity and introduce quality hand-off risks. Vertically integrated manufacturing consolidates processes under one roof. Understanding the risks of choosing the wrong manufacturing partner helps engineers avoid costly delays and quality issues in mission-critical programs.

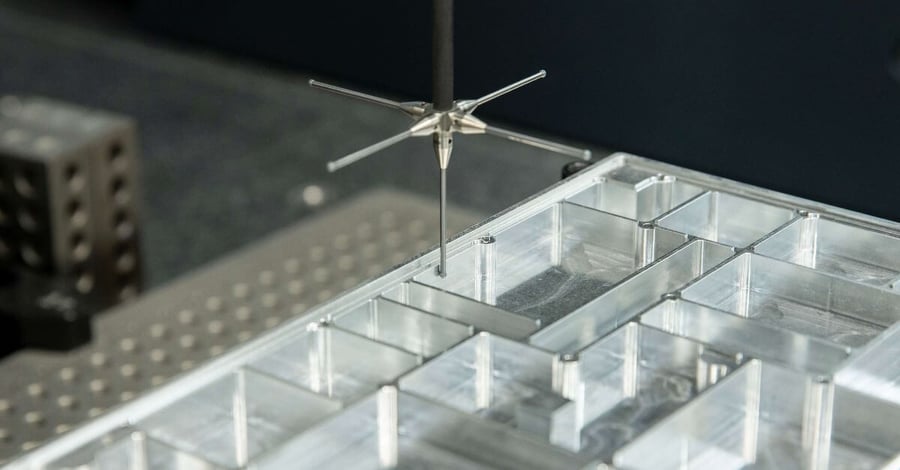

Precision Metalwork and CNC Machining

RF shield housings require tight tolerances and complex geometries to ensure proper gasket seating and electromagnetic performance. Selecting the right custom metal manufacturing partner with precision CNC capabilities ensures components meet the demanding requirements of hypersonic applications. CNC machining capabilities span vertical machining centers for plate-like components, horizontal machining centers for larger parts, and 5-axis machining for complex geometries without multiple setups.

CNC machining delivers:

- Standard tolerances: ±0.25 mm (±0.010") for most applications

- Complex geometries: 5-axis capabilities eliminate positioning errors

- Material versatility: Aluminum 6061, superalloys, and specialized metals

- Integrated workflow: Direct transition to plating, coating, and assembly operations

Vertically integrated machining combines metal cutting with downstream processes. Shield housings receive plating or coating treatments immediately after machining, followed by form-in-place gasket dispensing.

RF Shielding and EMI Protection for Hypersonic Systems

Electromagnetic interference protection requirements in hypersonic systems exceed conventional aerospace standards. Custom RF shield manufacturing for high-performance defense applications requires integration of multiple specialized processes to achieve effective electromagnetic protection across extreme temperature ranges.

Shielding process integration includes:

- Precision machining: Creates metal housings with proper mating surface flatness

- Conductive plating: Nickel or silver plating enhances electrical conductivity

- Form-in-place dispensing: Automated systems maintain ±0.15 mm (±0.006") bead tolerances

- Converted components: Die-cut, waterjet-cut, or CNC-cut gaskets and absorbers

RF Shielding Process | Primary Application | Key Advantage |

CNC Machining | Metal shield housings | ±0.25 mm tolerances, complex 3D geometries |

Form-in-Place Dispensing | Conductive gaskets | Follows intricate contours, ±0.15 mm accuracy |

Die Cutting | Fabric gaskets | High-volume production, cost-effective |

Waterjet Cutting | Metal-backed gaskets | Thick materials, high compression loads |

Form-in-Place Gasket Manufacturing

Form-in-place gaskets provide sealing and electromagnetic shielding solutions uniquely suited to hypersonic applications. Choosing the right manufacturing process for electrically conductive gaskets depends on geometry complexity, production volume, and environmental requirements. Dispensed materials conform to complex three-dimensional surfaces impossible to seal with die-cut gaskets.

FIP capabilities include:

- Automated dispensing: CNC-controlled positioning with real-time monitoring

- Material flexibility: Parker Chomerics CHOFORM, Nolato TriShield, and Laird formulations

- Tight tolerances: ±0.10 mm to ±0.15 mm height control depending on gasket size

- Temperature range: Standard materials to 177°C (350°F), high-temp to 260°C (500°F)

Material selection depends on performance requirements. Parker Chomerics CHOFORM materials provide electromagnetic shielding with recommended compression of 20-30%. Nolato TriShield gaskets offer high shielding effectiveness in narrow profiles.

Read our Form-in-Place Gasket Guide.

Thermal Management Solutions for High-Speed Flight

Thermal interface materials represent critical components in hypersonic electronics cooling. Gap-filling thermal pads accommodate manufacturing tolerances and surface irregularities while maintaining thermal pathways. For hypersonics electronic manufacturing requiring advanced thermal management in sub-assemblies, proper material selection and application methods ensure reliable heat dissipation across mission profiles.

Thermal management options:

- Gap-filling pads: Henkel BERGQUIST materials with 1.5 to 5 W/mK thermal conductivity

- Phase change materials: Transition from solid to liquid for thermal buffering during high-G phases

- Dispensed gels: Automated placement with dimensional control comparable to die-cut pads

- Thermal coatings: High-emissivity coatings maximize radiative heat transfer

Die cutting delivers production quantities with dimensional tolerances of ±0.38 mm (±0.015") for standard solid materials. Advanced thermal coatings provide passive thermal management for external surfaces.

Related Content:

- How to Build Your Custom RF Shield: Complete manufacturing guide for hypersonic-compatible RF shielding solutions

- Custom Metal Parts Manufacturing: Advanced techniques for aerospace and defense applications

- Defense Thermal Management Components: Meeting military standards and specifications for extreme environments

- Form-in-Place Gasketing: Complete engineering guide to design and implementation

Precision Coatings for Extreme Environments

Surface treatments extend component capabilities in hypersonic environments. Thermal control coatings for spacecraft and satellites operating in extreme environments manage heat transfer through precise control of solar absorptance, thermal emittance, and optical properties — principles equally critical for hypersonic flight systems.

Coating capabilities:

- Thermal control: High-emissivity coatings with values above 0.8 across infrared wavelengths

- Solar reflectance: Low-absorptance coatings reduce thermal loading

- Electrical conductivity: Nickel or silver plating for enhanced RF performance

- Space qualification: Materials resist atomic oxygen, UV degradation, micrometeorite impact

Application processes maintain uniform coverage on complex geometries. Automated process controls monitor material flow rates, spray patterns, and cure parameters.

Read our Guide to Optical and Thermal Coatings.

Converting Capabilities Across Materials

Converting transforms raw materials into precisely dimensioned components. Die cutting delivers production volumes economically with steel rule dies. Waterjet cutting handles materials challenging for other methods using high-pressure water mixed with abrasive particles. CNC cutting provides flexible prototyping without physical tooling delays.

Converting Process | Typical Tolerances | Best Volume Range |

Die Cutting | ±0.25 mm to ±0.63 mm | High volume (1000+ units) |

Waterjet Cutting | ±0.38 mm | Low to high volume |

CNC Cutting | ±0.38 mm | Prototype to medium volume |

Form-in-Place | ±0.15 mm (bead height) | Prototype to medium volume |

Security and Compliance for Defense Applications

Hypersonic programs involve sensitive design data and classified performance specifications. Hypersonic missile defense component manufacturing programs require manufacturing partners to protect mission-critical information through comprehensive cybersecurity programs and facility access controls.

CMMC Level 2 and DFARS Requirements

Cybersecurity Maturity Model Certification Level 2 implements the 110 security controls specified in NIST SP 800-171. CMMC Level 2 certification requires assessed compliance by authorized third-party assessors.

Compliance requirements include:

- Access controls: Strong authentication and audit logging for engineering workstations

- Network segmentation: Manufacturing execution systems isolated with intrusion detection

- Data protection: Encryption and backup procedures for quality management systems

- Physical security: Badge-controlled entry and visitor escort requirements

Defense Federal Acquisition Regulation Supplement clauses mandate safeguarding of covered defense information. International Traffic in Arms Regulations controls export of defense articles and technical data.

Compliance Standard | Key Requirements | Manufacturing Impact |

CMMC Level 2 | 110 NIST controls, third-party assessment | Cybersecurity infrastructure, access controls |

DFARS 252.204-7012 | CUI safeguarding, incident reporting | Information system security, response capabilities |

ITAR Registration | U.S. persons only, data protection | Facility access controls, employee screening |

AS9100 | Aerospace quality management | Process controls, configuration management |

Visit the full resource center.

Quality Systems for Mission Success

AS9100 certification establishes aerospace-specific quality management requirements beyond ISO 9001 standards. First article inspection processes validate that manufacturing procedures produce components meeting all specifications before production begins.

Quality infrastructure includes:

- Coordinate measuring machines: Three-dimensional inspection of machined components

- Vision systems: Verify gasket placement and bead dimensions on FIP assemblies

- Statistical process control: Monitors dimensional characteristics throughout production

Material certification accompanies every production lot. Metal lot numbers trace back to mill certifications. Elastomer batch numbers link to material data sheets. Each manufactured component carries identification enabling tracking through production.

Frequently Asked Questions About Hypersonic Manufacturing

What temperatures must hypersonic components withstand?

Hypersonic components must survive surface temperatures from cryogenic conditions to 1648°C (3000°F) or higher, with sustained operation between 538°C and 1093°C (1000°F to 2000°F) across most surfaces. Leading edges experience the most extreme thermal conditions.

What manufacturing processes are essential for hypersonic systems?

Essential hypersonic manufacturing processes include precision CNC machining for metal components (±0.25 mm tolerances), form-in-place gasket dispensing for electromagnetic shielding, advanced coatings for thermal management, and converting capabilities for elastomeric materials. Vertically integrated facilities that combine these processes reduce supply chain complexity.

Why is CMMC Level 2 certification important for hypersonic manufacturing?

CMMC Level 2 certification ensures manufacturers implement the 110 security controls from NIST SP 800-171, protecting Controlled Unclassified Information (CUI) and sensitive design data throughout the hypersonic development process. This certification is increasingly required for defense contractors working on classified programs.

How do form-in-place gaskets differ from die-cut gaskets for hypersonic applications?

Form-in-place gaskets conform to complex three-dimensional surfaces with automated dispensing systems that maintain ±0.15 mm (±0.006") bead height tolerances. Die-cut gaskets work well for flat mating surfaces but cannot follow intricate contours required in many hypersonic assemblies.

What materials can withstand hypersonic flight environments?

Hypersonic-capable materials include superalloys for structural components, ultra-high temperature ceramics (UHTCs) for leading edges, carbon-carbon composites for thermal protection, and specialized high-temperature elastomers rated to 260°C (500°F) for sealing applications. Material selection depends on specific temperature, vibration, and electromagnetic requirements.

What quality certifications should hypersonic manufacturing partners have?

Critical certifications include AS9100 for aerospace quality management, ISO 9001 for general quality systems, ITAR registration for handling controlled technical data, and CMMC Level 2 for cybersecurity. These certifications demonstrate capability to handle sensitive programs and maintain quality throughout production.

How does vertical integration benefit hypersonic component manufacturing?

Vertical integration consolidates multiple processes — CNC machining, plating, form-in-place dispensing, coating, and converting — under one quality system. This reduces supply chain complexity, eliminates quality hand-off risks, shortens lead times, and ensures consistent process control throughout manufacturing.

Next Steps:

- CMMC Compliance in Manufacturing: What prime contractors need to know when selecting subcontractors

- Missile Defense Component Manufacturing: Compliance and quality standards for defense contractors

- Vertical Integration at Modus Advanced: Learn how consolidated manufacturing reduces complexity and risk

- Form-in-Place Gasket Engineering Guide: Deep dive into FIP design, materials, and implementation

Partner with Modus Advanced for Hypersonic Manufacturing

Hypersonic component manufacturing demands expertise across multiple disciplines. At Modus Advanced, we combine precision machining, advanced converting, form-in-place dispensing, thermal management, and specialized coatings under one quality system.

Our capabilities include:

- CMMC Level 2 certification: Protects your sensitive program information

- ITAR registration: Authorized handling of controlled technical data

- AS9100 and ISO 9001: Aerospace manufacturing excellence

- Engineering team: More than 10% of workforce provides DFM guidance

- Vertical integration: Machining, plating, FIP, and converting under one roof

See It In Action:

- RF Shield Manufacturing Partner Selection: See how engineers evaluate manufacturing partners for mission-critical RF shielding

- Choosing the Right Metal Manufacturing Partner: Real-world guidance on partner evaluation for precision metalwork

- Space Critical Components Case Study: Learn how Modus delivers precision components for extreme environments

- Custom Aerospace Manufacturing: Discover our complete capabilities for mission-critical aerospace applications

Vertically integrated manufacturing eliminates supply chain complexity. Your shield housings receive CNC machining, plating, form-in-place gasket dispensing, and converted material assembly within our facility. When service members' lives depend on your hypersonic systems, choose a manufacturing partner who understands what's at stake.