Custom RF Shield Manufacturing: Choosing the Right Manufacturing Partner

July 29, 2025

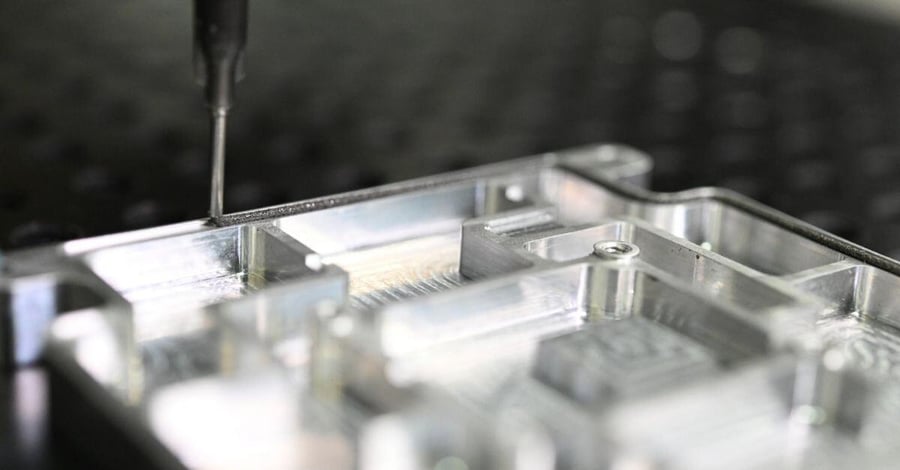

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Manufacturing partner selection is critical: The complexity of custom RF shield manufacturing requires specialized expertise, quality systems, and proven experience with RF applications

- Design collaboration improves outcomes: Working with manufacturers early in the design phase prevents costly redesigns and ensures manufacturability from the start

- Vertical integration reduces risk: Partners who can handle multiple processes under one roof minimize shipping delays, communication errors, and quality inconsistencies

- Quality certifications matter: Look for ISO 9001 and AS9100 certifications, plus demonstrated experience with RF-specific testing and validation requirements

- Engineering support is essential: Manufacturing partners with on-staff engineers can provide design feedback, material selection guidance, and troubleshooting throughout the project lifecycle

Custom RF shields protect critical electronic systems from electromagnetic interference that could compromise performance or even threaten lives. In aerospace applications, RF interference can disrupt navigation systems. In medical devices, it can cause life-support equipment to malfunction.

The stakes are high, which makes selecting the right custom RF shield manufacturing partner absolutely crucial. Custom RF shield manufacturing combines precision engineering, specialized materials knowledge, and advanced manufacturing processes that most general contractors simply cannot provide.

This guide will help you evaluate potential partners and establish the collaborative relationships needed to bring your custom RF shield designs from concept to production successfully.

Read our complete guide on RF shielding.

Understanding Custom RF Shield Manufacturing Complexity

Custom RF shields represent some of the most technically demanding components in modern electronics. These electromagnetic shielding devices must provide precise electromagnetic isolation while meeting strict mechanical, thermal, and environmental requirements.

The custom RF shield manufacturing process typically involves multiple disciplines working in concert. Metal housings require precision machining to maintain tight tolerances. Gaskets and O-rings need specialized elastomeric materials filled with conductive particles.

Surface treatments and platings must provide long-term corrosion resistance and electrical continuity. Each component must integrate seamlessly with others to create an effective electromagnetic barrier. A single gap or material inconsistency can compromise the entire RF shield's effectiveness, making manufacturing precision absolutely critical.

Essential Manufacturing Partner Qualifications

Industry Certifications and Standards for RF Shield Manufacturing

Quality certifications provide a baseline for evaluating custom RF shield manufacturing capabilities. ISO 9001 certification demonstrates commitment to quality management systems and continuous improvement processes. For aerospace and defense applications, AS9100 certification is essential.

This standard extends ISO 9001 requirements to address the additional quality, safety, and reliability requirements specific to aerospace manufacturing. ITAR registration becomes necessary when working on defense-related projects. This certification ensures proper handling of controlled technical data and compliance with export regulations.

Key certifications to verify:

- ISO 9001: Quality management system certification demonstrating process control

- AS9100: Aerospace quality management standard for critical applications

- ITAR: International Traffic in Arms Regulations compliance for defense projects

- CMMC: Cybersecurity Maturity Model Certification for defense contractors

Manufacturing Capabilities and Equipment

RF shield manufacturing requires specialized equipment and diverse processing capabilities across multiple material types and manufacturing processes. The complexity of RF shields demands partners who can handle both metallic housing components and elastomeric sealing elements with precision.

CNC machining provides the dimensional accuracy needed for complex metal housings and structural components. This process achieves standard tolerances of ±0.005" (±0.13 mm) for critical RF shield features. Form-in-place (FIP) gasket dispensing systems enable precise application of conductive elastomeric materials directly onto housings.

These automated systems achieve standard tolerances of ±0.0004" (±0.010 mm) for gasket placement and dimensional control. The precision of FIP dispensing makes it ideal for complex geometries where traditional gasket cutting methods would be impractical.

| Manufacturing Process | Material Applications | Standard Tolerances | Typical Applications |

|---|---|---|---|

| CNC Machining | Aluminum, steel, copper alloys | ±0.005" (±0.13 mm) | Metal housings, complex geometries |

| FIP Dispensing | Conductive elastomers | ±0.0004" (±0.010 mm) | Precision gaskets, custom seals |

| Custom Gasket Manufacturing | Various materials | Process-dependent | Intricate shapes, mixed materials |

Converting processes for elastomeric materials used in RF shield gaskets and seals follow established tolerance standards based on material type and thickness. These tolerances apply regardless of whether the parts are produced through die cutting, waterjet cutting, or CNC knife cutting methods.

| Material Thickness | Film Materials | Solid/Dense Materials | Sponge/Foam Materials |

|---|---|---|---|

| Up to 0.25" (6.3 mm) | ±0.010" (±0.25 mm) | ±0.015" (±0.38 mm) | ±0.025" (±0.63 mm) |

| 0.25" to 0.50" (6.3-12.7 mm) | N/A | ±0.030" (±0.76 mm) | ±0.040" (±1.02 mm) |

| Over 0.50" (12.7 mm) | N/A | N/A | ±0.050" (±1.27 mm) |

Note: Tolerances shown are for dimensions under 1.0". Larger dimensions and specific material requirements may require adjusted tolerances.

The choice of converting process depends on material properties, part complexity, and production volume requirements. For instance: die cutting excels for high-volume production of simple geometries, while waterjet cutting provides superior edge quality for intricate shapes and mixed-material applications.

Engineering Support and Design Collaboration

Manufacturing partners with dedicated engineering staff provide invaluable design support throughout the project lifecycle. These engineers understand both RF principles and manufacturing constraints, enabling them to identify potential issues before they become costly problems. Design for manufacturability (DFM) reviews should be standard practice.

During these reviews, manufacturing engineers evaluate designs for producibility, suggest material alternatives, and recommend process optimizations. This collaborative approach prevents expensive redesigns and ensures optimal manufacturing efficiency from project inception.

Engineering support services to expect:

- DFM reviews: Early design evaluation and optimization recommendations

- Material selection: Guidance on RF performance vs. manufacturability trade-offs

- Tolerance analysis: Realistic assessment of achievable dimensional accuracy based on actual process capabilities

- Process planning: Optimal manufacturing sequence and quality checkpoints

Read the complete Design for Manufacturability Guide.

Evaluating Custom RF Shield Manufacturing Partner Capabilities

Proven RF Shield Experience

Generic manufacturers may claim RF shield capabilities, but specialized experience makes a significant difference in project success. Look for partners who can demonstrate successful completion of similar custom RF shield projects in your industry. Request examples of previous RF shield work, including technical challenges overcome and performance results achieved.

Partners should be able to discuss specific materials used, testing methods employed, and lessons learned from past projects. Case studies and customer testimonials provide insight into the partner's problem-solving abilities and collaborative approach. Pay particular attention to how they handled unexpected challenges or requirement changes during project execution.

Quality Systems and Testing Capabilities

Custom RF shield performance depends on precise manufacturing execution and thorough validation testing. Quality systems must address both dimensional accuracy and electromagnetic performance requirements. Statistical process control (SPC) methods help maintain consistent manufacturing outcomes.

Partners should demonstrate their use of control charts, capability studies, and other statistical tools to monitor and improve processes. Testing capabilities should include both in-process quality checks and final validation testing. RF performance testing requires specialized equipment and expertise that not all manufacturers possess.

Quality System Element | Purpose | Implementation Level |

Statistical Process Control | Monitor process consistency | Real-time data collection |

Measurement Systems | Dimensional verification | Coordinate measuring machines |

RF Testing Equipment | Shielding effectiveness validation | Network analyzers, chambers |

Documentation Control | Traceability and records | Digital quality management |

Vertical Integration Advantages

Partners with multiple in-house capabilities offer significant advantages for custom RF shield manufacturing. Vertical integration reduces the number of vendors involved, minimizing communication errors and shipping delays. Single-source responsibility simplifies project management and accountability.

When issues arise, you work with one partner rather than coordinating between multiple suppliers with potentially conflicting priorities. Cost benefits often result from eliminating markup between processing steps and reducing freight expenses. Material waste decreases when multiple operations occur under one roof without intermediate packaging and shipping.

Design Collaboration Best Practices

Early Partner Engagement in RF Shield Development

Involving manufacturing partners during the design phase yields better outcomes than waiting until designs are finalized. Early engagement allows manufacturers to influence material selections, dimensional requirements, and processing approaches while changes are still relatively easy to implement. Preliminary design reviews help identify potential manufacturing challenges before detailed engineering begins.

These discussions can reveal alternative approaches that maintain performance while improving manufacturability. Regular design iterations with manufacturing input lead to optimized solutions. This collaborative approach balances performance requirements with practical manufacturing constraints to achieve the best overall results.

Material Selection Collaboration

Custom RF shield materials must balance electromagnetic performance, mechanical properties, environmental resistance, and manufacturability. This complex optimization benefits significantly from manufacturing partner expertise. Conductive elastomers require careful selection based on filler type, particle size, and base polymer characteristics.

Manufacturing partners understand how these material properties affect processing parameters and final performance. Metal housing materials involve trade-offs between RF performance, machinability, corrosion resistance, and cost. Experienced partners can recommend alternatives that meet specifications while optimizing manufacturing efficiency.

Material Category | RF Performance | Manufacturing Considerations | Cost Factors |

Nickel/Graphite Elastomers | 90+ dB attenuation | Moderate processing complexity | Economy option |

Silver/Copper Filled | 100+ dB attenuation | Requires careful handling | Premium performance |

Aluminum Housings | Good conductivity | Excellent machinability | Lower material cost |

Copper Alloys | Superior conductivity | More challenging machining | Higher material cost |

Tolerance and Specification Optimization

Unrealistic tolerances drive up manufacturing costs without necessarily improving performance. Collaborative tolerance analysis helps identify where tight control is essential and where relaxed requirements are acceptable. Manufacturing partners can provide guidance on achievable tolerances for different processes and materials.

This information helps optimize specifications for both performance and cost-effectiveness. Statistical tolerance analysis methods account for variation in multiple manufacturing steps. This approach provides more realistic assessments of final assembly performance than worst-case calculations.

Visit our RF Shielding Resource Center.

Establishing Successful Manufacturing Partnerships

Communication Protocols

Clear communication channels prevent misunderstandings and ensure timely resolution of issues. Establish regular review meetings to discuss progress, address concerns, and coordinate schedule changes. Technical communication should involve engineering personnel from both organizations.

This direct engineer-to-engineer interaction facilitates faster problem-solving and better technical decision-making. Documentation standards ensure consistent information sharing throughout the project. Establish agreed-upon formats for drawings, specifications, test reports, and other technical communications.

Project Management and Scheduling

Realistic project schedules account for design iterations, prototype testing, and potential manufacturing challenges. Experienced partners help establish achievable milestones based on similar project experience. Contingency planning addresses potential issues before they become critical problems.

Discuss alternative approaches for technical challenges and backup plans for supply chain disruptions. Regular progress reviews maintain project momentum and identify issues early. These reviews should include technical progress, schedule adherence, and quality metrics to ensure overall project health.

Quality Assurance Integration

Quality planning should begin during the design phase rather than after manufacturing starts. Collaborative development of quality plans ensures both parties understand requirements and acceptance criteria. Inspection and testing protocols require agreement on methods, frequency, and acceptance criteria.

These protocols should address both in-process controls and final acceptance testing. Corrective action procedures establish how nonconformances will be addressed. Quick resolution of quality issues prevents schedule delays and maintains project momentum.

Read our Guide to Working with Custom Manufacturing Partners.

Frequently Asked Questions About Custom RF Shield Manufacturing

What makes custom RF shield manufacturing different from standard shielding?

Custom RF shields require specialized materials, precise tolerances, and application-specific design optimization that standard shielding solutions cannot provide. Each application demands unique electromagnetic, mechanical, and environmental performance characteristics.

How long does custom RF shield manufacturing typically take?

Lead times vary based on complexity, but typical custom RF shield projects range from 3-12 weeks depending on design requirements, material availability, and testing needs. Early partner engagement can significantly reduce these timelines.

What certifications are most important for RF shield manufacturers?

ISO 9001 provides baseline quality assurance, while AS9100 is essential for aerospace applications. ITAR registration is required for defense projects, and industry-specific certifications may be needed based on your application.

Why Modus Advanced Excels in Custom RF Shield Manufacturing

Modus Advanced combines deep RF shielding expertise with comprehensive manufacturing capabilities to deliver superior results for aerospace, defense, and medical device applications. Our engineering team — representing more than 10% of our staff — provides the technical depth needed for complex custom RF shield projects. Our vertically integrated approach handles everything from initial design consultation through final testing and delivery.

This comprehensive capability eliminates the coordination challenges and quality risks associated with multiple suppliers. Quality is embedded in everything we do, supported by AS9100 and ISO 9001 certifications plus ITAR registration for defense applications. Our robust quality systems ensure consistent results that meet the most demanding performance requirements.

The complexity of custom RF shield manufacturing demands partners with specialized expertise, proven experience, and comprehensive capabilities. Success requires early collaboration, clear communication, and shared commitment to quality excellence. When your application demands reliable electromagnetic protection, choose a partner who understands both the technical challenges and the manufacturing precision required to meet them consistently.