Selecting the Right Build to Print Manufacturer: Your Complete Guide to Partnership Success

June 12, 2025

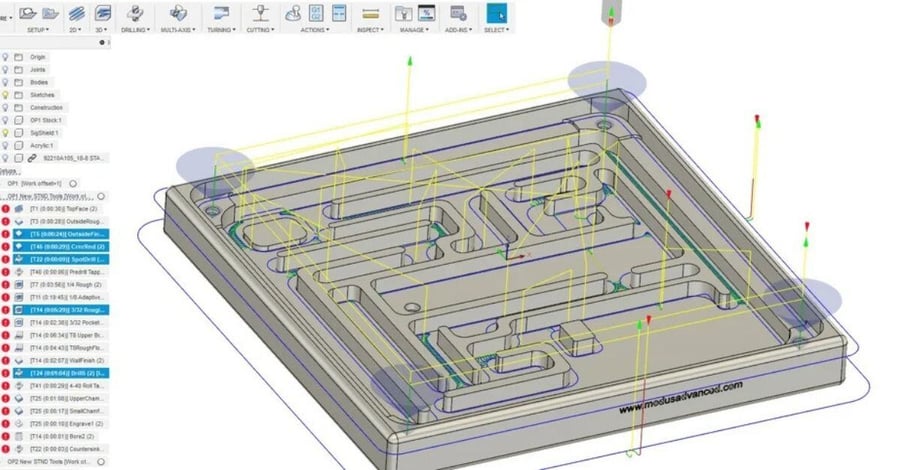

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Build to print manufacturers must demonstrate relevant industry certifications, with AS9100 for aerospace/defense and ISO 13485 for medical devices being essential baseline qualifications

- Manufacturing capabilities should include both primary processes and secondary operations under one roof to reduce lead times and quality risks

- Quality systems require statistical process control, advanced measurement capabilities, and documented procedures for validation and traceability

- Engineering support from your build to print manufacturer should include design for manufacturability feedback and technical problem-solving capabilities

- Regulatory compliance expertise becomes critical for ITAR, FDA, and other industry-specific requirements that impact your final product approval

Engineering teams in aerospace and defense, and medical device industries face a critical decision when selecting manufacturing partners. The stakes are high — these components often protect lives, ensure mission success, or enable breakthrough medical treatments. Choosing the wrong build to print manufacturer can result in costly delays, quality failures, or regulatory compliance issues that derail entire programs.

The right build to print manufacturer becomes an extension of your engineering team, translating your designs into precision components while maintaining the quality standards your applications demand. This selection process requires careful evaluation across multiple technical and operational dimensions.

definition

What is a Build to Print Manufacturer?

A build to print manufacturer produces components according to client-provided specifications and designs, maintaining complete client control over intellectual property while leveraging specialized manufacturing expertise and capabilities.

Essential Certification Requirements for Mission-Critical Applications

Industry certifications serve as the foundation for evaluating any build to print manufacturer in regulated industries. These certifications demonstrate a manufacturer's commitment to quality systems and their ability to meet stringent regulatory requirements.

The certification landscape varies significantly between industries, with each sector having specific requirements that directly impact your ability to bring products to market. Understanding these requirements helps narrow your search to qualified manufacturers from the start.

Certification | Industry Focus | Key Requirements | Typical Audit Frequency |

Aerospace/Defense | Quality management, risk management, configuration management | Annual surveillance | |

Medical Devices | Design controls, risk management, post-market surveillance | Annual surveillance | |

Defense/Military | Export control compliance, security protocols | Periodic compliance reviews | |

General Manufacturing | Quality management system fundamentals | Annual surveillance | |

CMMC Compliance | Defense Contractors | Cybersecurity controls, data protection | Triennial assessment |

AS9100 Certification for Aerospace and Defense

AS9100 certification represents the gold standard for aerospace and defense manufacturing. This certification builds upon ISO 9001 foundations while adding aerospace-specific requirements including configuration management, risk management, and product safety considerations.

When evaluating a build to print manufacturer's AS9100 certification, verify the scope covers your specific manufacturing processes. A certificate covering only assembly operations won't suffice if you need precision machining or specialized material processing.

Medical Device Specific Requirements

Medical device manufacturing requires ISO 13485 certification, which emphasizes design controls, risk management, and post-market surveillance. This certification ensures your build to print manufacturer understands the unique requirements of medical device production.

Additionally, evaluate their experience with FDA regulations, particularly if your components will be incorporated into Class II or Class III devices requiring premarket approval.

These certifications provide the regulatory foundation necessary for successful partnerships in mission-critical applications.

Manufacturing Capabilities: Beyond Basic Production

Manufacturing capabilities extend far beyond simple production capacity. The right build to print manufacturer offers comprehensive capabilities that eliminate the complexity of managing multiple vendors while ensuring consistent quality across all processes.

Vertical integration becomes particularly valuable when components require multiple manufacturing steps. Managing separate vendors for machining, coating, assembly, and testing introduces quality risks and extends lead times significantly.

Core Manufacturing Processes

Your build to print manufacturer should demonstrate expertise in the primary manufacturing processes required for your components:

- CNC Machining: Multi-axis capabilities, tight tolerance control, and material expertise

- Precision Cutting: Waterjet, laser, and die cutting for complex geometries

- Specialized Processes: Form-in-place dispensing, RF shielding, thermal management

- Assembly Operations: Component integration, testing, and validation

- Surface Treatments: Plating, coating, and finishing operations

Material Expertise and Handling

Specialized applications often require exotic materials with unique handling requirements. Your build to print manufacturer should demonstrate experience with materials relevant to your application, including proper storage, handling, and processing protocols.

For medical applications, this includes USP Class VI and FDA-approved materials. Aerospace applications may require titanium, Inconel, or specialized composites. Defense applications often involve materials with specific electromagnetic properties.

Secondary Operations and Value-Added Services

Secondary operations capability reduces your project management burden while improving quality consistency:

- Testing and validation services

- Packaging and logistics coordination

- Documentation and traceability systems

- Supplier management for specialized components

- Engineering change management

Comprehensive manufacturing capabilities enable your build to print manufacturer to serve as a true extension of your engineering team.

Quality Systems: Ensuring Consistent Excellence

Quality systems in mission-critical manufacturing must go beyond basic inspection and documentation. Advanced quality systems provide statistical process control, predictive quality management, and comprehensive traceability throughout the manufacturing process.

The sophistication of quality systems directly impacts your confidence in manufactured components, particularly for applications where failure is not an option. Evaluating these systems requires understanding both the technology and processes your build to print manufacturer employs.

Statistical Process Control and Monitoring

Advanced build to print manufacturers implement statistical process control (SPC) to monitor manufacturing processes in real-time. Key elements include real-time data collection, automated alerts for process variations, and control charts for trending analysis.

Measurement and Inspection Technology

Precision manufacturing requires advanced measurement capabilities that match your component tolerances. Critical capabilities include coordinate measuring machines (CMM), optical measurement systems, and proper calibration programs.

Documentation and Traceability Systems

Comprehensive documentation and traceability become essential for regulated industries. Effective traceability systems enable rapid response to quality issues while providing documentation necessary for regulatory compliance and customer requirements.

Case Study

How Flory Industries Maintains Quality from Suppliers and Simplifies Purchasing

Learn more about how Flory Industries has focused on a strategic sourcing model to build stronger, more fruitful relationships with core suppliers.

See HowEngineering Support: Adding Value Beyond Manufacturing

Engineering support from your build to print manufacturer should complement your internal design capabilities while providing manufacturing expertise you may lack internally. This collaborative approach often results in better designs and more efficient manufacturing processes.

The best build to print manufacturers assign dedicated engineering resources to your projects, creating a true partnership that extends beyond simple production services. This engineering support becomes particularly valuable during design optimization and manufacturing problem-solving phases.

Design for Manufacturability (DFM) Expertise

Effective DFM feedback from your build to print manufacturer can significantly impact both product cost and quality. This feedback should address manufacturing considerations while respecting your design intent and performance requirements.

Valuable DFM feedback includes:

- Tolerance optimization for manufacturing efficiency

- Material selection guidance based on manufacturing processes

- Geometry modifications to improve manufacturability

- Cost reduction opportunities without performance compromise

- Quality risk identification and mitigation strategies

Technical Problem-Solving Capabilities

Manufacturing challenges inevitably arise during production, particularly for complex or innovative designs. Your build to print manufacturer should demonstrate technical problem-solving capabilities that address these challenges efficiently.

Strong engineering support teams provide:

- Root cause analysis for manufacturing issues

- Alternative process development when needed

- Fixture and tooling design expertise

- Material compatibility assessments

- Process optimization recommendations

Industry-Specific Knowledge

Engineering support becomes most valuable when your build to print manufacturer understands the unique requirements of your industry. This knowledge enables proactive identification of potential issues and optimization opportunities.

Industry-specific engineering expertise ensures your manufacturing partner understands the full context of your component requirements and performance expectations.

Visit the full resource center on all custom manufacturing services.

Regulatory Compliance: Navigating Complex Requirements

Regulatory compliance in aerospace, defense, and medical device manufacturing involves multiple layers of requirements that directly impact your ability to bring products to market. Your build to print manufacturer must demonstrate both understanding and implementation of relevant regulatory requirements.

Compliance failures can result in significant delays, costly remediation, or complete program cancellation. Selecting a build to print manufacturer with proven regulatory expertise reduces these risks significantly.

ITAR and Export Control Compliance

Defense applications often require ITAR compliance, which governs the export and handling of defense-related technologies. Your build to print manufacturer must demonstrate proper ITAR registration and implementation of required security controls.

Key ITAR compliance elements include:

- Proper facility security and access controls

- Personnel screening and citizenship verification

- Technical data protection and handling procedures

- Export documentation and approval processes

- Audit trail and documentation requirements

FDA Regulations for Medical Devices

Medical device manufacturing involves complex FDA regulations that vary based on device classification and intended use. Your build to print manufacturer should understand these requirements and maintain appropriate quality systems.

Critical FDA compliance areas include:

- Quality system regulations (21 CFR Part 820)

- Biocompatibility testing and documentation

- Risk management according to ISO 14971

- Clinical data requirements for device approval

- Post-market surveillance and reporting

Cybersecurity Requirements

Defense contractors increasingly face cybersecurity requirements under the Cybersecurity Maturity Model Certification (CMMC) framework. Your build to print manufacturer should implement appropriate cybersecurity controls to protect sensitive technical information.

Regulatory compliance expertise ensures your manufacturing partnership supports rather than complicates your path to market approval.

Evaluating Manufacturing Capacity and Scalability

Production capacity and scalability considerations ensure your build to print manufacturer can support your program from prototype through full production. Understanding these capabilities prevents future bottlenecks and ensures consistent supply chain performance.

Capacity evaluation extends beyond simple production volume to include surge capability, lead time management, and supply chain resilience. These factors become critical for programs with aggressive timelines or variable demand patterns.

Production Volume Capabilities

Your build to print manufacturer should demonstrate capacity for your expected production volumes while maintaining quality standards. This includes both current capacity and planned expansion capabilities.

Key capacity considerations include:

- Current production capacity across relevant processes

- Equipment availability and utilization rates

- Staffing levels and skill availability

- Facility space and expansion potential

- Supply chain capacity for materials and components

Lead Time Management

Consistent lead time performance becomes critical for program success, particularly when your components are on the critical path for system integration. Your build to print manufacturer should demonstrate proven lead time management capabilities.

Effective lead time management includes:

- Realistic scheduling based on capacity constraints

- Buffer management for unexpected demand variations

- Priority handling for urgent requirements

- Communication systems for schedule visibility

- Contingency planning for supply chain disruptions

Supply Chain Resilience

Recent global events have highlighted the importance of supply chain resilience. Your build to print manufacturer should demonstrate robust supply chain management that minimizes disruption risks.

Strong supply chain management includes multiple supplier relationships, inventory management strategies, and contingency planning for critical materials and components.

Technology Integration and Industry 4.0 Capabilities

Modern manufacturing increasingly relies on digital integration and Industry 4.0 technologies that improve quality, efficiency, and traceability. Your build to print manufacturer should demonstrate investment in relevant technologies that support your program requirements.

Technology integration becomes particularly important for complex components requiring precise process control and comprehensive documentation. These capabilities often differentiate leading manufacturers from traditional production shops.

Digital Manufacturing Integration

Digital manufacturing technologies enable seamless integration between design and production while providing real-time visibility into manufacturing processes. Your build to print manufacturer should leverage these technologies effectively.

Key digital manufacturing capabilities include:

- AD/CAM integration for direct programming

- Manufacturing execution systems (MES) for process control

- Digital quality management systems

- Real-time production monitoring and reporting

- Predictive maintenance for equipment reliability

Data Management and Analytics

Advanced data management enables continuous improvement and predictive quality management. Your build to print manufacturer should collect, analyze, and act upon manufacturing data to improve outcomes continuously.

Effective data management provides insights into process optimization opportunities while ensuring complete traceability for regulatory compliance requirements.

Technology investment demonstrates your build to print manufacturer's commitment to continuous improvement and competitive manufacturing capabilities.

Making the Final Selection: A Strategic Partnership Decision

Selecting the right build to print manufacturer requires balancing multiple technical, operational, and strategic factors while considering your specific program requirements. This decision impacts not just component quality and cost, but your ability to bring innovations to market successfully.

The evaluation process should include site visits, reference checks, and pilot projects that demonstrate actual capabilities rather than relying solely on presentations and documentation. A structured evaluation framework ensures consistent assessment across potential partners.

The right build to print manufacturer becomes a strategic partner that accelerates your innovation while ensuring the quality and compliance your applications demand. When lives depend on your innovation, choosing a manufacturing partner who understands what's at stake makes all the difference.

Partner with Modus Advanced to bring your mission-critical innovations to market with confidence. Because when precision matters and time counts, you need a build to print manufacturer who delivers excellence every time.