What is Build to Print Manufacturing?

May 8, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Build to print manufacturing is a partnership where manufacturers create components based on client-provided designs and specifications.

- This approach offers advantages in specialized expertise, reduced overhead, faster production, and quality assurance.

- Engineers should evaluate potential build to print partners based on certifications, manufacturing capabilities, quality systems, and engineering support.

- Modus Advanced offers a unique engineering-first approach to build to print manufacturing with vertical integration capabilities.

- Companies using build to print manufacturing can focus their internal resources on core competencies while leveraging external manufacturing expertise.

In today's complex manufacturing landscape, engineering teams face mounting pressure to bring innovations to market faster while maintaining rigorous quality standards. This is particularly true in aerospace, defense, and medical device sectors where precision isn't just about performance — it's often about saving lives.

Build to print manufacturing offers a strategic solution to these challenges, allowing engineering teams to focus on design while leveraging specialized manufacturing expertise.

Definition

What is Build to Print Manufacturing?

Build to print manufacturing is a specialized partnership where manufacturers produce components or products according to engineering specifications provided by the client, maintaining the client's complete design control while leveraging the manufacturer's production expertise. This approach allows engineering teams to focus on innovation and core competencies while accessing specialized manufacturing capabilities without the overhead of developing these capacities in-house.

The Foundation: Understanding Build to Print Manufacturing

Build to print manufacturing represents a specialized manufacturing partnership where a manufacturer produces components, subsystems, or complete products according to engineering specifications provided by the client. Unlike design-build approaches, the client maintains complete control over design aspects while outsourcing the manufacturing expertise.

This approach creates a clear division of responsibilities: you own the intellectual property and design specifications, while your manufacturing partner executes production with precision. The manufacturer works from detailed technical specifications, CAD files, and quality requirements that you provide, translating your designs into physical reality.

Build to print manufacturing partnerships thrive on clear communication and comprehensive documentation. The effectiveness of this relationship depends on thorough documentation of specifications, tolerances, and quality requirements.

Strategic Benefits of Build to Print Manufacturing

Build to print manufacturing offers several strategic advantages for engineering teams in high-precision industries. Understanding these benefits helps determine when this approach aligns with your production needs and organizational goals.

Access to Specialized Manufacturing Expertise and Engineering Services

Working with a dedicated build to print manufacturing partner gives you access to specialized expertise that would be prohibitively expensive to develop in-house. This includes:

- Advanced manufacturing processes like CNC machining, form-in-place gaskets, and RF shielding

- Expertise in working with specialized materials like conductive elastomers or aerospace-grade metals

- Knowledge of industry-specific quality requirements and compliance standards

- Capabilities with specialized equipment and technologies

The right manufacturing partner has already invested millions in equipment, talent, and process development so you don't have to. This specialized focus results in higher quality outcomes and production efficiencies.

Reduced Overhead and Infrastructure Costs

Developing in-house manufacturing capabilities requires significant capital investment and ongoing operational costs. Build to print manufacturing allows you to:

- Eliminate capital expenditures for specialized manufacturing equipment

- Reduce facility requirements and associated overhead

- Minimize staffing requirements for manufacturing operations

- Convert fixed manufacturing costs to variable costs that scale with production needs

These financial advantages are particularly valuable for companies focusing resources on R&D and design innovation rather than manufacturing infrastructure.

Accelerated Time to Market

Speed matters in today's competitive landscape. Build to print manufacturing can significantly accelerate your production timeline through:

- Immediate access to manufacturing capacity without equipment acquisition delays

- Parallel processing of multiple production steps through vertical integration

- Elimination of learning curves associated with new manufacturing processes

- Ready scalability from prototype to production volumes

When your build to print partner already has the processes, equipment and expertise in place, you can achieve dramatic time savings compared to developing these capabilities internally.

Enhanced Quality Control and Compliance

Quality standards in aerospace, defense, and medical applications are exceptionally rigorous, with little margin for error. Specialized build to print manufacturers offer:

- Established quality management systems designed for high-precision manufacturing

- Experience with industry-specific certifications (AS9100, ISO 9001, ITAR)

- Dedicated quality engineering staff and advanced measurement equipment

- Documented procedures for validation, verification, and traceability

These quality capabilities aren't just about meeting technical specifications—they're about ensuring consistency across production runs and maintaining full compliance with regulatory requirements.

When to Choose Build to Print Manufacturing

Build to print manufacturing is particularly valuable in specific scenarios. Understanding these situations helps engineering teams make informed decisions about their manufacturing strategy.

Specialized Component Manufacturing

For components requiring specialized manufacturing processes, build to print manufacturing often provides the most efficient path forward. This approach is ideal when:

- Components require precision beyond standard manufacturing tolerances

- Production involves specialized materials with unique handling requirements

- Manufacturing processes require specialized equipment or technical expertise

- Components must meet rigorous industry-specific standards

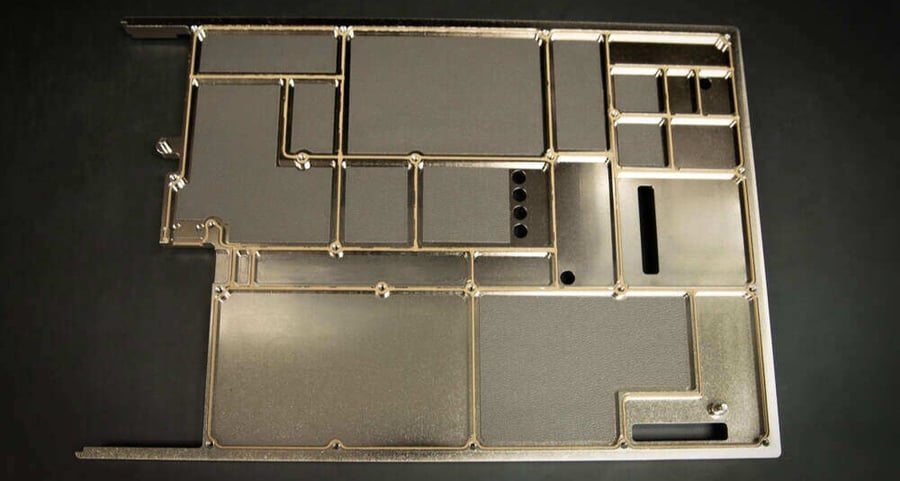

Examples include precision-machined RF shields, specialized gaskets, or complex electromechanical assemblies requiring multiple manufacturing processes.

Prototype to Production Transition

The transition from prototype to production represents a critical phase where build to print manufacturing offers significant advantages:

- Faster scaling without internal manufacturing constraints

- Consistent quality from prototype through production

- Reduced risk through proven manufacturing expertise

- Design feedback from manufacturing experts to optimize for production

A build to print partner with both prototyping and production capabilities ensures continuity through this critical transition without requiring you to manage multiple vendors.

Focus on Core Competencies

Companies focused on design innovation often benefit from outsourcing manufacturing to specialized partners:

- Engineering teams can concentrate on next-generation design

- R&D resources remain focused on competitive differentiation

- Management attention stays on strategic priorities rather than manufacturing operations

- Company resources align with value-creating activities

This strategic focus on core competencies often results in both better designs and better manufacturing outcomes through specialized expertise in each domain.

Regulatory-Intensive Applications

For products subject to rigorous regulatory oversight, build to print manufacturing with certified partners streamlines compliance:

- Partners maintain relevant certifications and compliance documentation

- Quality systems are designed for regulatory requirements

- Established processes ensure consistent documentation

- Experience with regulatory submissions and audits

This regulatory expertise is particularly valuable in aerospace, defense, and medical device manufacturing where compliance requirements are extensive and complex.

Selecting Your Build to Print Manufacturing Partner

The success of your build to print manufacturing strategy depends significantly on selecting the right manufacturing partner. This decision requires careful evaluation across multiple dimensions relevant to your specific requirements.

Essential Certification and Compliance Capabilities

Proper certifications serve as a baseline qualification for any build to print manufacturing partner. For aerospace, defense, and medical applications, key certifications include:

Certification | Relevance | Industries |

AS9100 | Aerospace quality management system standard | Aerospace, Defense |

ISO 9001 | General quality management system | All Industries |

ITAR | International Traffic in Arms Regulations compliance | Defense, Military |

ISO 13485 | Medical device quality management system | Medical Devices |

CMMC | Cybersecurity Maturity Model Certification | Defense, Government |

Beyond these formal certifications, your partner should demonstrate familiarity with industry-specific standards relevant to your product, such as MIL-SPEC requirements or FDA regulations.

These certifications reflect a demonstrated commitment to quality systems and compliance requirements in your industry.

Manufacturing Process Capabilities

A build to print manufacturing partner should offer the specific manufacturing capabilities required for your components. Evaluate potential partners based on:

- Core manufacturing processes (CNC machining, die cutting, FIP dispensing)

- Secondary operations (finishing, assembly, testing) and vertical integration capabilities

- Material expertise related to your application

- Equipment capabilities and technology level

- Capacity for your production volume requirements

The ideal partner offers all required manufacturing processes under one roof, reducing lead times and quality risks associated with moving parts between multiple vendors.

Quality Systems and Process Controls

Effective quality systems are essential for consistent, reliable manufacturing outcomes. Look for partners with:

- Comprehensive quality management systems with documented procedures

- Statistical process control and monitoring

- Advanced measurement and inspection capabilities

- Established non-conformance management processes

- Continuous improvement methodologies

Request specific information about quality metrics, such as first-pass yield, defect rates, and on-time delivery performance to assess quality capabilities objectively.

Engineering Support and Technical Expertise

While you maintain design ownership in a build to print relationship, manufacturing engineering expertise remains essential. Value-adding partners offer:

- Design for manufacturability (DFM) feedback

- Material selection guidance based on manufacturing considerations

- Process optimization recommendations

- Technical problem-solving capabilities

- Industry-specific manufacturing knowledge

Engineering support from your manufacturing partner helps identify potential issues before production begins, reducing costs and accelerating timelines.

The Modus Advanced Approach to Build to Print Manufacturing

At Modus Advanced, our approach to build to print manufacturing centers on being the OBVIOUS CHOICE for engineering teams in aerospace, defense, and medical device industries. This approach combines technical expertise, vertical integration, and a focus on critical applications where quality and reliability directly impact safety and performance.

Engineering-First Build to Print Manufacturing

With engineers comprising over 10% of our staff, we approach build to print manufacturing from an engineering perspective. This engineering-first approach enables:

- Technical collaboration with your design team

- Manufacturing feedback grounded in engineering principles

- Deep understanding of performance requirements beyond print specifications

- Problem-solving capabilities for manufacturing challenges

Our engineering team provides value throughout the manufacturing process, from initial design review through production and quality verification.

Submit a DesignVertically Integrated Manufacturing Capabilities

Our vertical integration strategy eliminates the complexity and delays associated with managing multiple vendors. For build to print manufacturing, this means:

- Multiple manufacturing processes under one roof

- Seamless transition between manufacturing steps

- Consistent quality control across all processes

- Reduced lead times and simplified project management

- Decreased shipping costs and handling risks

This approach is particularly valuable for complex components requiring multiple manufacturing processes, such as RF shields that combine machining, FIP gasket dispensing, and assembly operations.

Quality Systems Designed for Critical Applications

Our quality systems are designed for applications where failure is not an option:

- AS9100 and ISO 9001 certified quality management systems

- ITAR registration for defense applications

- Advanced measurement and inspection capabilities

- Statistical process control for consistent manufacturing outcomes

- Documented validation and verification procedures

These quality capabilities ensure that manufactured parts consistently meet design specifications and perform as intended in critical applications.

Visit the full resource center on all custom manufacturing services.

Frequently Asked Questions About Build to Print Manufacturing

Engineers often have specific questions about build to print manufacturing as they evaluate this approach for their projects. Here are answers to some of the most common questions we encounter.

What's the difference between build to print and design-build manufacturing?

Build to print manufacturing means the client provides complete design specifications and the manufacturer focuses solely on production according to those specifications. Design-build manufacturing, in contrast, involves the manufacturer participating in both the design and production processes. Build to print keeps all intellectual property and design control with the client, while design-build shares these responsibilities.

Who is responsible for design changes in a build to print arrangement?

In build to print manufacturing, the client maintains full responsibility for design changes. When design modifications are needed, the client updates specifications and documentation, then provides these updates to the manufacturing partner. The manufacturer implements these changes according to the revised specifications but doesn't initiate design modifications independently.

How detailed must specifications be for build to print manufacturing?

Specifications for build to print manufacturing should be comprehensive, including detailed technical drawings, material requirements, tolerance specifications, surface finish requirements, and quality standards. The most successful build to print relationships include clear documentation of all critical-to-function characteristics and inspection criteria to ensure the manufactured part meets performance requirements.

Can build to print manufacturers help optimize designs for manufacturability?

While build to print manufacturers don't modify designs without client approval, experienced partners often provide valuable design for manufacturability (DFM) feedback. This guidance highlights potential manufacturing challenges, cost reduction opportunities, or quality improvements that the client can incorporate into design revisions before production begins.

How are quality standards maintained in build to print manufacturing?

Quality in build to print manufacturing relies on three key elements: clear specifications from the client, robust quality systems from the manufacturer, and effective communication between both parties. The client defines quality requirements, while the manufacturer implements quality control processes, inspection protocols, and documentation systems to verify that specifications are consistently met.

What industries commonly use build to print manufacturing?

Build to print manufacturing is common in industries with complex components, specialized manufacturing requirements, and rigorous quality standards. Aerospace, defense, medical devices, telecommunications, and specialized electronics industries frequently leverage this approach for critical components and subsystems requiring precision manufacturing.

Is build to print manufacturing more expensive than in-house production?

While per-unit costs might appear higher with build to print manufacturing, the total cost of ownership is often lower when considering capital equipment investments, facilities, staffing, training, and overhead required for in-house manufacturing. Build to print manufacturing converts fixed manufacturing costs to variable costs and eliminates the need for specialized equipment and expertise development.

How does intellectual property protection work in build to print manufacturing?

In build to print relationships, the client retains all intellectual property rights to the design. Manufacturing partners typically sign non-disclosure agreements and confidentiality provisions to protect proprietary designs. For particularly sensitive applications, ITAR-registered or security-cleared manufacturers provide additional protection for controlled technical information.

These frequently asked questions provide a starting point for engineers considering build to print manufacturing. Each project has unique requirements, so consulting with an experienced manufacturing partner about your specific needs is always recommended.

Building Success Through Partnership

Build to print manufacturing represents more than just outsourced production—it's a strategic partnership that allows engineering teams to focus on innovation while leveraging specialized manufacturing expertise. By clearly understanding what build to print manufacturing offers, when to use it, and how to select the right partner, engineering teams can accelerate development, reduce costs, and ensure consistent quality.

One day matters when bringing life-changing innovations to market. The right build to print manufacturing partner helps you make the most of every day by providing manufacturing expertise, quality systems, and technical capabilities that complement your design innovation.

Speak with one of our engineers today to discuss how our build to print manufacturing capabilities can support your next project. Because when lives depend on your innovation, choosing the right manufacturing partner matters.