Form-in-Place Seal Material Selection: Engineering Guide for Performance and Reliability

August 11, 2025

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- Material selection drives performance outcomes: Conductive fillers like silver/copper provide superior EMI shielding (>100 dB) while nickel/graphite options offer enhanced galvanic corrosion resistance for aluminum housings

- Curing method selection impacts production flexibility: Thermal curing enables same-day testing and shipping with better adhesion properties, while moisture curing accommodates temperature-sensitive substrates and cosmetic finishes

- Base elastomer properties determine environmental compatibility: Silicone elastomers provide -55°C to +125°C (-67°F to +257°F) temperature stability, while fluorosilicone formulations offer superior chemical resistance for harsh environments

- Compression requirements vary significantly by filler type: Silver-filled materials typically require 20-30% compression for optimal performance, while nickel/graphite formulations can achieve effective sealing at 10-50% compression ranges

- Particle size and distribution affect dispensing feasibility: Larger metallic particles in highly filled materials can restrict flow through small dispensing needles, particularly in extended-reach applications deeper than 6.35mm (0.25 inches)

What are Form-in-Place Seals and Why Material Selection Matters

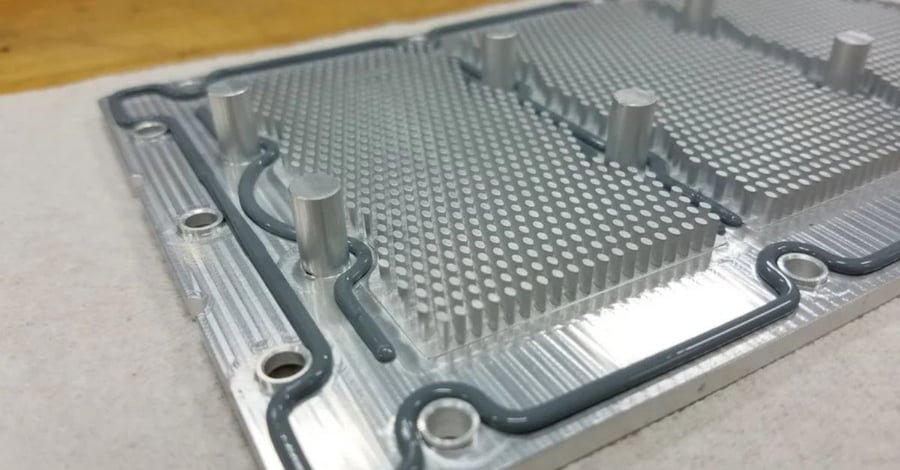

Form-in-place seals represent one of the most versatile sealing solutions available to engineers designing electronic enclosures, medical devices, and aerospace systems. Unlike traditional gaskets that require precise cutting and fitting, form in place seal technology creates custom seals by dispensing liquid elastomers directly onto component housings where they cure to form perfectly fitted barriers.

The success of any form-in-place sealing application depends heavily on selecting the right material formulation for your specific performance requirements. Engineers must balance electrical conductivity needs, environmental resistance, compression characteristics, and dispensing feasibility to achieve reliable long-term sealing performance.

Form-in-place seals are dispensed as liquids that cure in position, eliminating the dimensional variations and installation challenges associated with pre-cut gaskets. This precision becomes critical in applications where sealing failures could compromise patient safety, mission success, or system reliability.

Visit our Complete Form-in-Place Gasket Resource Center.

Understanding Form-in-Place Seal Material Architecture

Form-in-place seal materials consist of base elastomers combined with functional fillers that provide specific performance characteristics. The base elastomer determines fundamental properties like temperature resistance, chemical compatibility, and mechanical flexibility, while fillers add conductivity, flame retardancy, or specialized performance features.

Most industrial applications utilize silicone-based elastomers as the foundation material due to their exceptional temperature stability and chemical resistance. Silicone elastomers maintain their sealing properties across temperature ranges from -55°C to +125°C (-67°F to +257°F), making them suitable for both aerospace applications experiencing extreme temperature cycling and medical devices requiring autoclave sterilization.

The filler materials determine whether your form in place seal provides electrical conductivity for EMI shielding applications or remains non-conductive for environmental sealing. Conductive fillers include silver, copper, aluminum, nickel, and graphite particles, each offering different electrical and mechanical characteristics that affect both performance and cost.

Base Elastomer Selection Criteria for Form-in-Place Seals

Silicone elastomers dominate form-in-place seal applications due to their superior environmental resistance and temperature stability. These materials resist oxidation, ozone degradation, and UV exposure while maintaining flexibility across wide temperature ranges that would cause other elastomers to become brittle or soft.

Fluorosilicone formulations provide enhanced chemical resistance for applications exposed to fuels, solvents, or aggressive cleaning agents. These specialized elastomers maintain sealing integrity when exposed to jet fuels, hydraulic fluids, and industrial chemicals that would cause standard silicones to swell or degrade.

Synthetic rubber bases offer cost advantages for less demanding applications but typically sacrifice temperature range and chemical resistance. Engineers should carefully evaluate whether the cost savings justify the reduced performance envelope, particularly in aerospace and medical applications where failure consequences are severe.

Read the Parker Chomerics EMI Shielding Materials Guide.

Conductive Filler Systems for EMI Shielding Applications

Conductive form-in-place seals rely on metallic filler particles to provide electrical pathways that attenuate electromagnetic interference. The selection of filler material significantly impacts shielding effectiveness, galvanic compatibility with housing materials, and dispensing characteristics.

Silver-based fillers deliver the highest electrical conductivity and superior shielding performance, typically achieving >100 dB attenuation across broad frequency ranges. Silver/copper combinations provide excellent conductivity while reducing material costs compared to pure silver systems. These formulations work well with most metal housing materials and provide reliable long-term performance.

Silver/aluminum fillers offer outstanding shielding effectiveness with enhanced galvanic compatibility for aluminum housings. The aluminum particles help prevent galvanic corrosion that can occur when dissimilar metals are in electrical contact, making these formulations ideal for lightweight aerospace enclosures and telecommunications equipment.

Nickel and Graphite Filler Characteristics

Nickel/graphite filler systems provide robust EMI shielding performance with excellent galvanic corrosion resistance, particularly valuable for aluminum housing applications. These materials typically achieve >90 dB shielding effectiveness while offering superior environmental stability in harsh conditions including salt spray exposure and temperature cycling.

The graphite component contributes to electrical conductivity while the nickel coating provides corrosion resistance and improved particle dispersion throughout the elastomer matrix. This combination creates materials that maintain consistent electrical properties even after extended exposure to humidity, temperature extremes, and chemical environments.

Filler System | Typical Shielding Effectiveness | Volume Resistivity | Primary Advantages |

Silver/Copper | >100 dB | 0.002-0.004 Ohm-cm | Highest conductivity, broad frequency response |

Silver/Aluminum | >100 dB | 0.003-0.005 Ohm-cm | Aluminum compatibility, weight reduction |

Silver/Nickel | >100 dB | 0.005 Ohm-cm | Corrosion resistance, stability |

Nickel/Graphite | >90 dB | 0.03 Ohm-cm | Cost effectiveness, aluminum compatibility |

Curing System Selection and Process Implications

The curing mechanism determines both manufacturing flexibility and final material properties. Thermal curing systems offer superior performance characteristics and faster production turnaround, while moisture curing provides compatibility with temperature-sensitive substrates and specialized application requirements.

Thermal curing occurs when form-in-place seal materials are exposed to elevated temperatures, typically 100-150°C (212-302°F) for 30-60 minutes depending on material formulation and section thickness. This controlled curing process enables same-day testing and shipping while producing materials with superior adhesion properties and lower compression set characteristics.

The controlled thermal environment eliminates variability associated with ambient humidity and temperature conditions, ensuring consistent curing across all parts in a production batch. Thermally cured materials typically exhibit adhesion strengths double that of moisture-cured equivalents, providing enhanced reliability for demanding applications.

Moisture Curing for Specialized Applications

Moisture curing systems cure at room temperature when exposed to ambient humidity, typically requiring 24 hours at 22°C (72°F) and 50% relative humidity for complete cross-linking. These systems accommodate substrates that cannot withstand elevated temperatures, including plastic housings with external cosmetic finishes and temperature-sensitive electronic components.

Moisture curing enables dispensing onto conductive painted surfaces and plated plastic housings where thermal curing temperatures would damage finish quality or dimensional stability. This flexibility makes moisture curing systems valuable for consumer electronics and medical devices where aesthetic requirements are critical.

The extended curing time requires careful production planning and adequate work-in-process storage, but eliminates the need for oven capacity and reduces energy consumption. Engineers must account for the longer lead times when planning production schedules and prototype development timelines.

Curing Method | Cure Temperature | Cure Time | Substrate Compatibility | Key Benefits |

Thermal | 100-150°C (212-302°F) | 30-60 minutes | Heat-resistant materials | Same-day testing, superior adhesion |

Moisture | 22°C (72°F) | 24 hours | Temperature-sensitive substrates | Low energy, aesthetic finishes |

UV Light | Room temperature | 5-15 minutes | UV-transparent housings | Rapid cure, precise control |

Dual-cure | Variable | 2-stage process | Complex geometries | Shadow area curing, flexibility |

Material Performance Specifications and Selection Guidelines

Selecting the optimal form in place seal material requires understanding how different formulations perform under specific operating conditions. Engineers must evaluate electrical requirements, environmental exposure, compression characteristics, and dispensing feasibility to identify the best material for their application.

Compression set resistance determines how well a seal maintains its sealing force after prolonged compression. Materials with low compression set values retain their original thickness and sealing pressure throughout the product lifecycle, while high compression set materials gradually lose sealing effectiveness as they take a permanent set under load.

Volume resistivity specifications indicate the electrical conductivity of conductive formulations, with lower values indicating higher conductivity and better shielding performance. However, the relationship between volume resistivity and practical shielding effectiveness depends on gasket geometry, compression levels, and housing design characteristics.

Temperature Performance and Environmental Resistance

Operating temperature range defines the service envelope where materials maintain their sealing and electrical properties. Standard silicone-based formulations typically operate reliably from -55°C to +125°C (-67°F to +257°F), covering most aerospace, medical, and telecommunications applications.

Specialized high-temperature formulations can extend the upper operating limit to +200°C (+392°F) for applications near engine compartments or high-power electronics, while low-temperature variants maintain flexibility down to -65°C (-85°F) for space applications and arctic operations.

Chemical resistance varies significantly between base elastomer types and filler systems. Standard silicone formulations resist most common solvents and cleaning agents, while fluorosilicone variants provide superior resistance to fuels, hydraulic fluids, and aggressive chemicals commonly found in aerospace and industrial applications.

Read our Complete Form-in-Place Gasket Guide.

Dispensing Considerations and Material Compatibility

Material viscosity and particle size distribution directly affect dispensing feasibility and production efficiency. Highly filled conductive materials with large metallic particles can create flow restrictions in small dispensing needles, particularly for extended-reach applications where gasket paths are located deep within housing pockets.

Low-viscosity formulations enable faster dispensing cycles and better flow into complex geometries, but may exhibit more slump on vertical surfaces or three-dimensional dispensing paths. Engineers must balance dispensing speed requirements with the need for dimensional stability during curing.

Particle size becomes critical when bead dimensions approach the size of individual filler particles. Gasket heights below 0.76mm (0.030 inches) with highly filled materials can exhibit surface irregularities where individual particles create visible texture effects that may affect sealing performance or visual appearance.

Dispensing Equipment and Process Optimization

CNC dispensing systems provide the precision required for consistent form-in-place seal application, with positioning accuracy typically within ±0.025mm (±0.001 inches). These systems accommodate materials with varying viscosity and particle loading through adjustable pressure, flow rate, and needle size selections.

Material handling considerations include:

- Temperature control: Maintaining consistent material temperature prevents viscosity variations that affect dispensing accuracy

- Mix ratio precision: Two-component systems require accurate ratio control to ensure proper curing and final properties

- Needle selection: Larger particles require correspondingly larger needle diameters to prevent clogging

- Dispensing pressure: Higher-viscosity materials need increased pressure while maintaining flow rate consistency

Advanced Material Formulations for Specialized Applications

Aerospace and defense applications often require specialized form-in-place seal materials that combine multiple performance characteristics. Jet fuel resistant formulations maintain electrical conductivity and sealing performance after prolonged exposure to aviation fuels including Jet A, JP-5, JP-8, and specialized military formulations.

These advanced materials resist fuel-induced swelling, shrinkage, and embrittlement while continuing to provide consistent EMI/RFI shielding effectiveness greater than 60 dB from 200 MHz to 10 GHz. The materials maintain their properties across temperature ranges from -54°C to +125°C (-65°F to +257°F) with UL 94 V-0 flammability ratings.

Medical device applications

may require materials that meet USP Class VI biocompatibility standards while providing environmental sealing for life-support equipment. These formulations undergo extensive testing to ensure they do not leach harmful substances that could affect patient safety or device performance.

Quality Standards and Certification Requirements

Manufacturing form-in-place seals for critical applications requires adherence to stringent quality standards including AS9100 for aerospace applications and ISO 13485 for medical devices. These standards ensure consistent material properties, dimensional accuracy, and performance reliability through documented quality management systems.

Key quality considerations include:

- Material traceability: Complete documentation of material lot numbers and certification data

- Process validation: Demonstrated repeatability of dispensing parameters and curing conditions

- Performance testing: Verification of shielding effectiveness, compression set, and environmental resistance

- Statistical process control: Ongoing monitoring of critical dimensions and material properties

The combination of certified materials and validated processes ensures form-in-place seals meet the demanding requirements of mission-critical applications where failure is not acceptable.

Optimizing Material Selection for Project Success

Successful form in place seal implementation

begins with clearly defining performance requirements and operating conditions. Engineers should establish minimum shielding effectiveness levels, operating temperature ranges, chemical exposure profiles, and compression loading conditions before evaluating material options.

Material cost represents only a small fraction of total project cost when development time, quality assurance, and potential failure consequences are considered. Selecting proven materials with comprehensive technical support typically provides better overall project economics than attempting to minimize material cost through unproven alternatives.

Early engagement with manufacturing partners during material selection helps identify potential dispensing challenges and processing requirements that could affect lead times or production feasibility. This collaborative approach prevents costly redesign cycles and ensures selected materials are compatible with available production capabilities.

Frequently Asked Questions About Form-in-Place Seal Materials

What is the difference between form-in-place seals and traditional gaskets?

Form-in-place seals are dispensed as liquids directly onto the component surface where they cure in position, creating a custom-fitted seal that eliminates the tolerances and installation challenges associated with pre-cut gaskets.

How do I choose between conductive and non-conductive form-in-place seal materials?

Select conductive materials when EMI shielding is required, typically achieving >90 dB attenuation. Non-conductive materials are suitable for environmental sealing where electrical isolation is needed.

What compression levels work best for form-in-place seals?

Compression requirements vary by material type: silver-filled formulations typically require 20-30% compression, while nickel/graphite materials can achieve effective sealing at 10-50% compression ranges.

Can form-in-place seals withstand autoclave sterilization?

Yes, properly formulated silicone-based materials can withstand repeated autoclave cycles at 121°C (250°F) and maintain their sealing and electrical properties.

Engineering Excellence in Form-in-Place Seal Applications

When your innovations protect lives or enable mission-critical systems, material selection becomes fundamental to your success. Form-in-place seal technology offers unmatched versatility for creating reliable barriers in the most demanding applications, but achieving optimal performance requires deep understanding of material science and manufacturing processes.

Modus Advanced combines comprehensive material expertise with vertically integrated manufacturing capabilities, helping engineers navigate complex material selection decisions while ensuring production feasibility. Our engineering team — more than 10% of our staff — provides technical guidance on material compatibility, dispensing optimization, and quality requirements that accelerate your development timeline.

From rapid prototyping through production scaling, we deliver form-in-place seal solutions that meet your exact performance requirements while maintaining manufacturing efficiency. Our AS9100, ISO 9001, and ITAR certifications ensure your critical applications receive the quality and security standards they demand.

Ready to optimize your form-in-place seal material selection for your next project? Contact our engineering team for comprehensive material guidance and quotes within 24-48 hours.