SigShield™ Turnkey Machined RF Shields – Wait, What?

May 5, 2021

Manufactured with Speed and Precision

The manufacturing capabilities you need and the engineering support you want, all from a single partner.

Submit a DesignKey Points

- SigShield™ is a product realization process that delivers machined aluminum RF shields with Nolato Trishield form-in-place gaskets, manufactured entirely at Modus Advanced's Livermore, CA facility.

- The vertical integration model of SigShield™ reduces typical lead times to just 2-3 weeks, approximately half the time of traditional multi-vendor approaches.

- SigShield™ is especially valuable for engineers with tight deadlines who require AS9100 quality systems and ITAR compliance for their RF shields.

- By handling all manufacturing processes under one roof (machining, plating, gasket dispensing, and optional thermal pads/microwave absorbers), Modus can anticipate issues early and make course corrections before they impact timelines.

- SigShield™ was developed specifically to address challenges in the quick-turn RF shield market, where traditional multi-vendor approaches often led to delays and complications.

Blogs, white papers, videos and pillar pages talking about machined RF shields - the idea is or was to start creating inbound content in 2019 to attract more people to our website. It’s my understanding that if we did a good job publishing content, our engineering friends would somehow just get it and start specifying our products and services. In case you didn’t know, our customers are supposed to be 60% sold by the time someone from Modus™ actually talks with them! I absolutely love the idea, but in today’s content overloaded world, I’m not convinced the model works.

How about we skip the sales pitch and just go straight to educating our internal teams and customers using the same basic content? I know, some of you would prefer we try to sell something! I just find it hard to believe that customers are actually absorbing the materials we’re publishing when our reports tell us the average time on recent blog posts is a blazing 10 seconds! I know we work with some seriously intelligent customers, so there’s no doubt in my mind they’re absorbing 4 pages of content in 10 seconds. Sure, they are!

I’ve probably already lost many of you, so I’m going to assume, if you’re still reading this post, you are probably a Modus™ employee who would like to be able to say you are one who actually reads our content. Excellent! Since I’m a man of few words, let’s get down to it!

As many of you know, we officially launched SigShield™ earlier this year. The purpose of this post is to give you a high-level overview of SigShield™. We’re going to cover the who, what, when, where, why and how. We will also sprinkle in some talking points. I just want to make sure we’re all on the same page.

SigShield: So Much More than RF Shielding.

Let's get a few of the basics out of the way:

- SigShield™ is a product realization process that results in a physical product.

- The product is a machined aluminum RF shield with a Nolato Trishield form-in-place gasket.

- Modus Advanced, Inc. manufacturers the RF shields in Livermore, CA.

- SigShield™ was originally developed to serve the needs of engineers looking for turnkey shields in two to three weeks.

Who might be interested in SigShield™?

Shoot, I already let the cat out of the bag! We have identified a few typical candidates. They’re going to be an engineer or buyer working for a company manufacturing electronic test equipment (spectrum analyzers) or communications equipment. Of course, there are others who are going to be interested as well. We would love to hear from them!

What is SigShield™?

SigShield™ is a product realization process. The SigShield™ process is the combination of the Modus™ Idea to Ignition™ methodology, Nolato Trishield form-in-place gaskets and the resulting benefits to our customers. We will leave the what conversation at a high level for now.

When does the SigShield™ product realization process make sense?

We’ve heard a lot of opinions on this, but the common thread is when 'time is of the essence'. If you’re an engineer with tight deadlines, our two to three-week lead times will probably be attractive. If there’s a requirement for the machined shields to be made by a company who has an AS9100 quality system, even better. If you combine the shorter lead times and AS9100 quality requirements with ITAR, well, enough said!

Where does the SigShield™ product realization happen?

Where should probably be approached in the context of the physical manufacturing location. The SigShield™ product realization process physically takes place in Livermore, CA. Machining of the aluminum, dispensing of the form-in-place gasket and die cutting of the optional thermal pads and microwave absorbers are all done under one roof.

Visit the Modus RF Shielding Resource Center

Why did we create the SigShield™ product realization process?

Thanks for asking! The quick answer is, prior to developing SigShield™, we were having a difficult time helping our customers execute on their promises to their end-customers. Probably the most common issue we ran into was trying to help our machine shop friends deliver quick-turn projects. Prior to the introduction of SigShield™, Modus™ always batted last.

Shields manufactured by outside shops would arrive via UPS overnight freight and inevitably, we would get a request the same morning to expedite the dispensing process. We love the phrase, “Come on man, it’s only a gasket. Can’t you just dispense it today and ship tonight?” I'm laughing while I’m writing this because it’s very true. It’s only a gasket! A gasket that requires a fair amount of programming time and processing time to apply correctly. Oh yeah, and then there’s the little fluid dynamics hurdle we address on each and every job.

How does the SigShield™ product realization process happen in about half the lead time of the typical multi-vendor model?

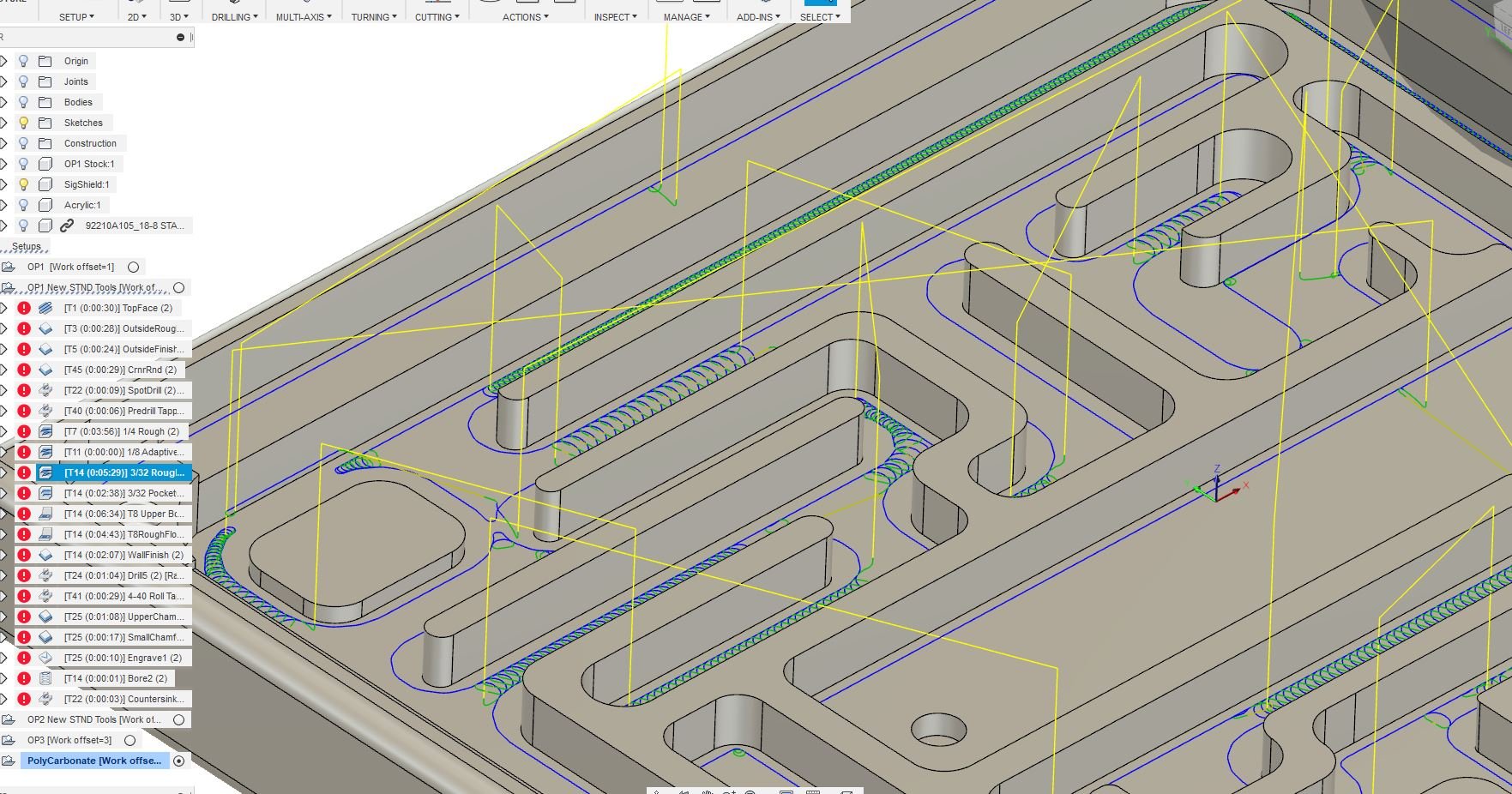

Let’s stick with our general strategy of keeping it pretty high-level today. The quick answer is a simple vertical integration model. We’re using both horizontal and vertical milling machines to manufacture the aluminum RF shields. In case you’re wondering, yes, they’re name brand machines.

After the shields are plated to the customer’s specification, we install threaded inserts if needed, and then dispense the electrically conductive EMI shielding gasket. Manufacturing the complete shield in one location gives us the ability to look ahead and address issues in advance. The built-in look-ahead helps us make course corrections well in advance and this leads to better project outcomes.

While we’re educating, a few more bullets regarding how we use the SigShield™ brand name. SigShield™ is a product realization process. In short, it’s a process that results in a product.

Read Everything You Need To Know About RF Shielding

This is how we would like to use SigShield™ in conversation:

- “The SigShield™ product realization process.”

- “Have you heard about SigShield™? It's a product re…”

- “What are the chances of getting 5 quick-turn machined RF shields made with Nolato Trishield gaskets? Can you put them through your SigShield™ product realization process?”

- “We're able to satisfy your demand by machining the RF shields in house and dispensing a Nolato Trishield form-in-place gasket using our SigShield™ product realization process.”

The following doesn't really work:

- “Would you please pass me the SigShield™?” SigShield™ is a process, not a product.

- “Sorry, what? Oh yes, I would like to order 2 SigShields and a side of fries please!” It's not a food or something you might smoke!

- “My SigShields™ were lost in transit. Can I get two more?”

Since we're doing a SigShield™ A to Z, let's cover some options!

Options as in, would you like cheese with that Impossible Burger? No, well maybe.

When installed in an electronic box, some RF shield (or machined chassis) assemblies require thermal pads to help conduct heat away from a heat source. As the Nolato Production Partner in North America, Modus Advanced, Inc. stocks Nolato Compatherm sheets and also performs the secondary function of cutting thermal pads to size.

Microwave absorbing pads are also commonly used as part of RF shield assemblies. Modus stocks our own brand of HiHag microwave absorbers. As with the Compatherm pads, HiMag absorbers can be manufactured to your specification right here in Livermore, CA.

What did I miss?

Let's see; we covered inbound, the WWWWW&H, ways to use SigShield™ in conversation and a few options. Future content will include deeper dives to help our internal teams, and maybe a few folks on the outside understand how we're able to help — looking forward to your comments!