Test Equipment

Get your part manufactured to your specifications in half the typical lead time.

We strive to respond to all quotes within 24 hours or less

We UnderstandTest Equipment

One Day Matters

We believe that one day matters. That each day sooner we can help you bring an innovative new product to market, the more lives you can affect.

Our processes, and our team, are dedicated to helping you get your products to market as fast as humanly possible.

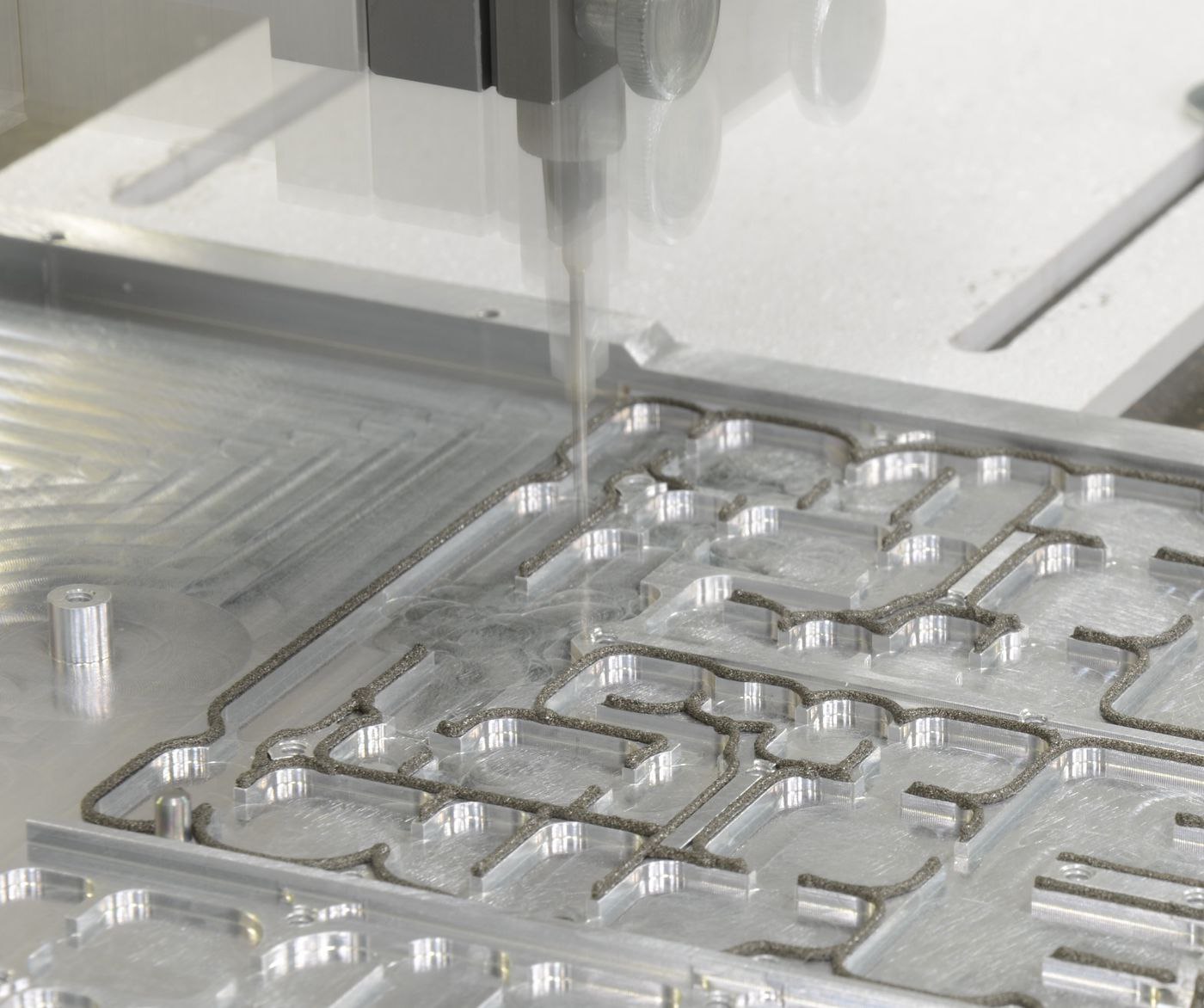

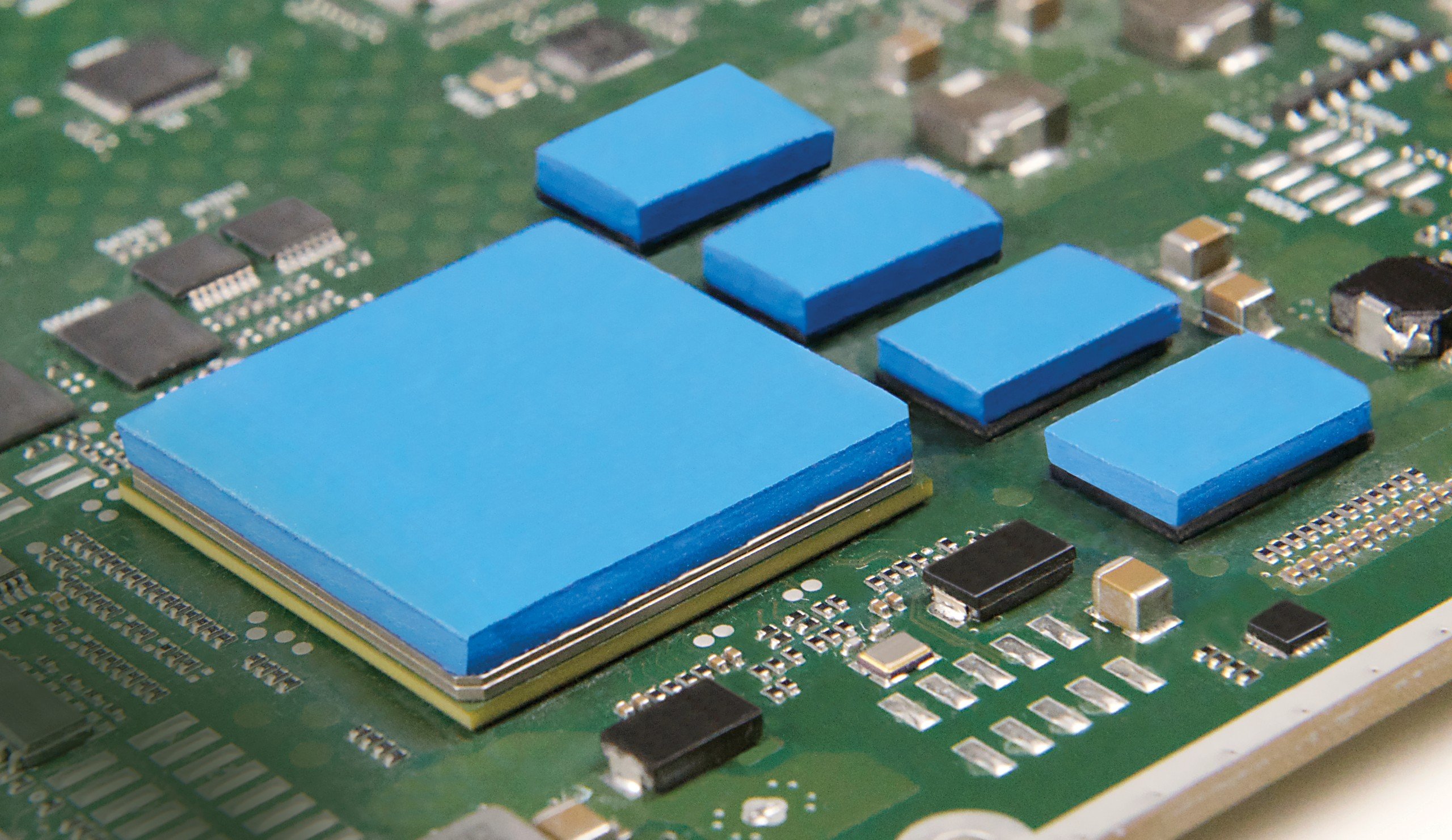

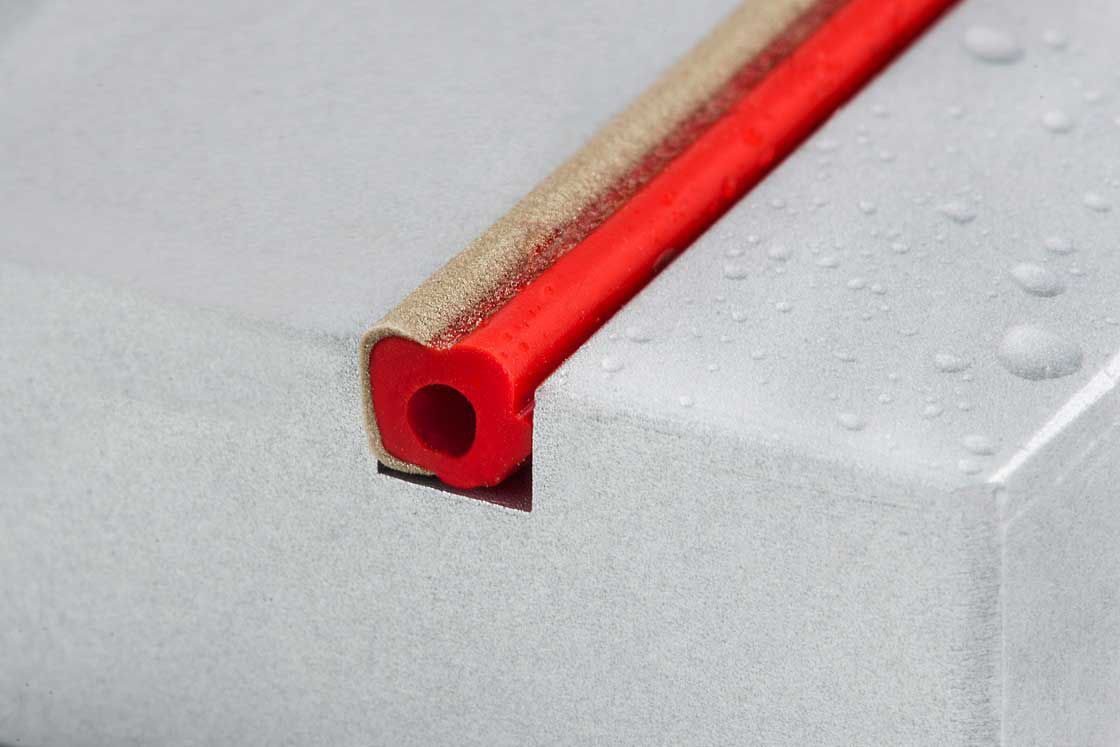

With eight core manufacturing processes under one roof, we are able to support the volumes you need from prototype to production. We can also support you across a breadth of different needs, including gasketing, machining, EMI/RF shielding, vibration isolation, sound dampening, and thermal management.

We want to be involved in helping shape your product from day one. Helping with quick turn or prototype work is one of our specialties.

.jpg)

Vertical Integration

We've taken steps to help provide our customers more concurrent manufacturing processes under one roof. Rather than sending a part to multiple different vendors for each step in manufacturing (e.g. CNC machining, platings and coatings, form-in-place dispensing, and the addition of thermal materials), you get it all from one partner, under a single roof.

You get to work with one manufacturing partner and benefit from shorter lead times and higher quality.

The SigShieldTM process is meant to simplify your life, by providing you more manufacturing steps from a single vendor.

Learn More

.jpg)

Speak to an Engineer Today

We strive to get every quote turned around in 24 hours or less to make sure you get the information you need faster.

Certifications and Standards to Meet Your Needs

A Few of Our Partners

We have a long history serving the test equipment industry.

“You can see Modus’ dedication to quality all the way down to the packaging they use to send our finished parts. Everything they do speaks to how much they care about delivering something perfect.”

Solutions for Test Equipment

Helping you build products that can stand up to the harshest conditions, performing in the situations when it matters most. We can help you meet your needs across a wide range of solutions, including gasketing, machining, EMI/RF shielding, vibration isolation, sound dampening, and thermal management.

With thousands of different materials and eight in-house processes, we pride ourselves on being your obvious choice for satellite and communication applications.

Signal Hound Improves Production

Learn how Signal Hound was able to overcome six months of production delays by finding a partner who offered vertical integration.

Read the Case Study

.png)

More Resources

Looking for more? Here are some great resources that will help you from design to ongoing procurement.

Custom RF Gasket Design for Missile Guidance Systems

What is Galvanic Compatibility? Definition and FAQs

RF Gasket Maintenance and Replacement in Long-Term Defense Contracts

Speak to an ENGINEER today.

We strive to get every quote turned around in 24 hours or less to make sure you get the information you need faster.