Educational Resources

Complete Design for Manufacturability Resource Center

Browse all of our educational resources about Design for Manufacturability.

Guide Articles Case Study.png?width=1024&height=768&name=www.modusadvanced.comhubfsDFM%20Pillar%20Hero%20(1).png)

Design for Manufacturability

What is Design for Manufacturability?

Design for manufacturability (DFM) is a systematic approach to product design that optimizes parts for efficient, cost-effective manufacturing processes. Also known as design for manufacturing, DFM integrates manufacturing considerations directly into the design process from the beginning rather than designing parts and then figuring out how to make them.

Guide

Download the Design for Manufacturability Guide

When your designs safeguard frontline missions, enable safe aerospace operations, or support patient outcomes, manufacturability is not just about meeting specifications—it is about delivering performance where failure is not an option. Read everything right on page (no form fill required), or get a PDF to keep!

Read the GuideFeatured Articles About RF Shielding

DFM Guidelines for Aerospace: Engineering for Mission Success

Learn how aerospace manufacturing constraints impact component design, tolerance specifications, and material selection for successful space and defense applications.

Design for Manufacturability Principles Every Engineer Should Know

Expert engineering guidance for optimizing designs across industries from aerospace to medical devices.

5 Manufacturing Methods for Shielding RF Signals

Learn how design for manufacturing (DFM) cost reduction strategies can slash production expenses by 15-30% through smart tolerance management, geometry optimization, and strategic material selection without compromising quality.

.jpg?width=1200&height=627&name=Design%20for%20Manufacturability%20in%20Medical%20Device%20Development%20Engineering%20Excellence%20Where%20Lives%20Depend%20on%20Precision%20(1).jpg)

The Best Process for Building a Custom RF Shield

This article explains how Design for Manufacturability (DFM) helps medical device teams meet strict regulatory standards, avoid costly redesigns, and ensure reliable performance.

.jpg?width=1200&height=627&name=Material%20Selection%20for%20Manufacturability%20Engineering%20Guidelines%20(1).jpg)

Material Selection for Manufacturability: Engineering Guidelines

Learn how to select materials for optimal manufacturability in engineering applications.

.jpg?width=1200&height=627&name=Design%20for%20Assembly%20Reducing%20Manufacturing%20Complexity%20and%20Cost%20(1).jpg)

Design for Assembly: Reducing Manufacturing Complexity and Cost

This article explores proven strategies to minimize complexity, streamline production, and enhance efficiency so you can deliver reliable products faster and more competitively.

Tolerance Design and Manufacturing Feasibility: Engineering Precision into Practice

Learn how tolerance design and manufacturing feasibility intersect to optimize product development.

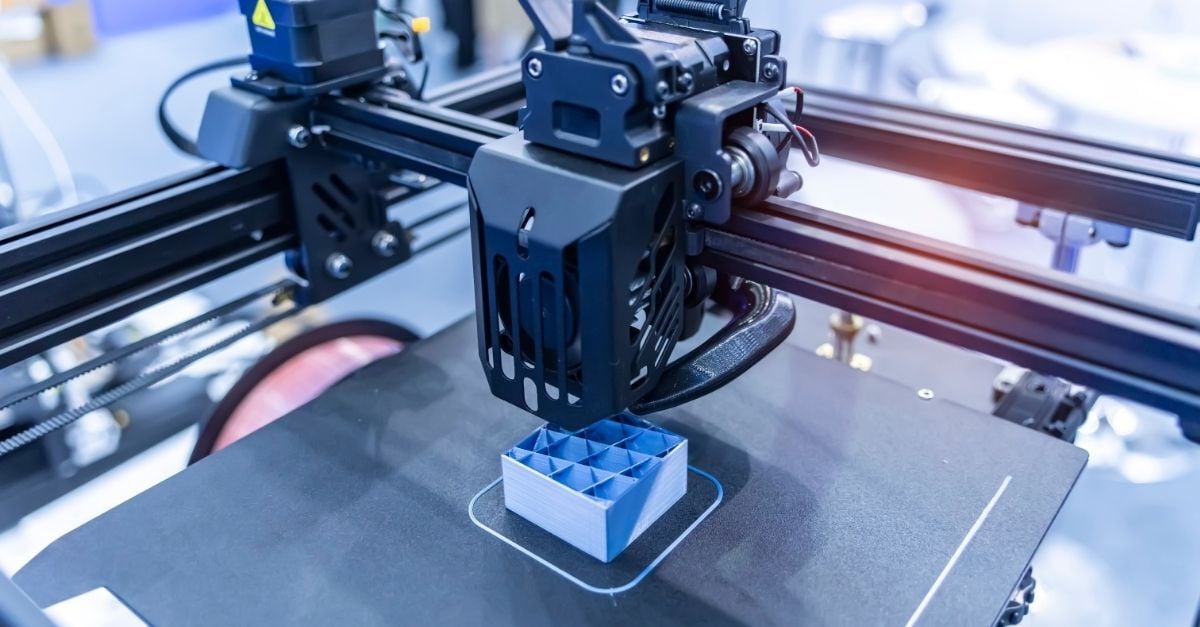

Design for Manufacturability in Rapid Prototyping: Engineering Your Path from Concept to Production

Master DFM principles for rapid prototyping success. Learn how material selection, tolerance optimization, and geometry simplification accelerate your path from concept to production while avoiding costly redesigns.

.jpg?width=1200&height=627&name=Design%20for%20Manufacturing%20Checklist%20Manufacturing%20Readiness%20Assessment%20for%20Critical%20Applications%20(1).jpg)

Design for Manufacturing Checklist: Manufacturing Readiness Assessment for Critical Applications

Learn how to conduct manufacturing readiness assessments with our comprehensive Design for Manufacturing checklist.

Designing for Manufacturing: When Casting Meets Machining in Production Strategy

Engineers developing new products face a critical decision that impacts both prototype development and long-term production success. Understanding the design differences between cast and machined parts can dramatically reduce lead times and manufacturing costs.

Design for Manufacturability: CNC Machined Metal Parts - Complete Engineering Guide

This comprehensive guide examines the most common design challenges encountered in CNC machined parts and provides actionable strategies to optimize your designs for faster, more cost-effective manufacturing without compromising functionality.

Design for Manufacturability: Form-in-Place (FIP) Dispensing

Form-in-place gasket design for manufacturability centers on optimizing both the metal housing design and gasket path specifications to reduce lead times and manufacturing complexity.

Design for Manufacturability: Optimizing Converted Parts and Custom Gaskets for Modern Manufacturing

Learn how design for manufacturability optimizes converted parts and custom gaskets manufacturing costs, lead times, and quality. Expert guidance on tolerance specifications, geometry complexity, material selection, and inspection requirements for aerospace, defense, and medical device applications.

![FIP4[v1]](https://www.modusadvanced.com/hs-fs/hubfs/2025%20Images/FIP4%5Bv1%5D.jpg?width=1920&height=1080&name=FIP4%5Bv1%5D.jpg)

Design for Manufacturability: How Quality Requirements Determine Lead Times & Costs

Learn how quality requirements impact manufacturing lead times and costs in this comprehensive guide to design for manufacturability (DFM).

.jpg?width=1200&height=627&name=CNC%20Machining%20Design%20Guidelines%20Why%20Your%20Beautiful%20CAD%20Model%20Costs%2010x%20More%20to%20Machine%20(1).jpg)

CNC Machining Design Guidelines: Why Your Beautiful CAD Model Costs 10x More to Machine

Learn why your CAD model costs 10x more to machine than expected. Discover CNC machining design guidelines that reduce costs by 300-500% through smart geometry choices, radius optimization, and manufacturing-focused design decisions.

Sharp Corners on CNC Machined Parts: The Impossible Feature That's Killing Your Timeline

The size of the radius you specify for your CNC machined parts has cascading effects throughout the entire manufacturing process. Each decision about corner geometry impacts programming time, machining efficiency, and quality control procedures.

CNC Machining Design Guidelines: Five-Axis vs. Three-Axis CNC Machined Parts

Learn how feature alignment determines whether your CNC machined parts require three-axis or five-axis manufacturing.

Custom RF Shield Manufacturing: Choosing the Right Manufacturing Partner

Custom RF shields protect critical electronic systems from electromagnetic interference that could compromise performance or even threaten lives.

The Hidden Cost of Tight Tolerance: Why 'Tighter' Isn't Always Better in Manufacturing

Learn why engineers' default to tight tolerances can increase manufacturing costs by 2-24x without functional benefit.

Tolerance in Product Design: How to Avoid Stack-Up Nightmares and Manufacturing Failures

Tolerance in Product Design: How to Avoid Stack-Up Nightmares and Manufacturing Failures

Case Study

Building a 10-Year Partnership with a DOD‑Telecom Partner

Learn how investment in building strong relationships and robust quality processes, systems and technology have driven a long-term relationship and supported the strategic growth of this telecommunications company.

See HowSubmit Your Design

Get Design Feedback from Our Team

Have a design that needs feedback? Get in touch with our engineering team today to get real-time feedback on how to make your design more effective and manufacturable.

Submit a Design

Get Started

Speak to an Engineer Today

Don’t take our word for it. Reach out and speak to one of our engineers about your part today and see the benefits for yourself. We strive to turn all quotes around 48 hours or less to get your part moving as quickly as possible.

Submit a Design